39

FORM 145.32-IOM5

ISSUE DATE: 08/30/2018

2

SECTION 2 – STARTUP AND OPERATION

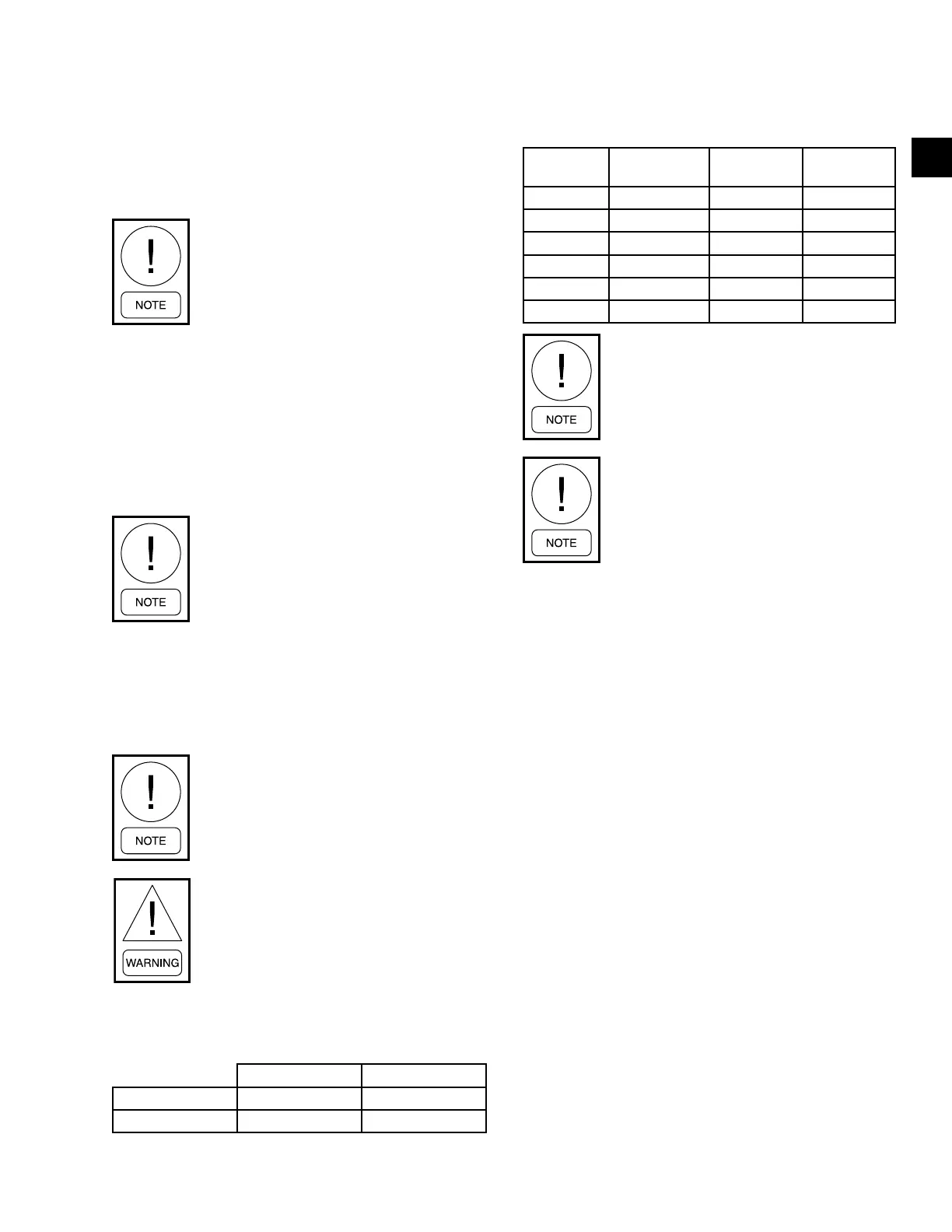

TABLE 24 - REFRIGERANT CHARGE (LBS)

UNIT

NUMBER OF

CIRCUITS

CIRCUIT 1 CIRCUIT 2

DSH024C 1 7.7 -

DSH036C 1 8.9 -

DSH048C 1 11.8 -

DSH060C 1 12.2 -

DSH096C 2 11.4 11.65

DSH120C 2 16 16.2

Factory split and charged units are

charged with two-thirds in condenser and

one-third in evaporator module.

Always charge with liquid when adding

R-410A refrigerant. Failure to do so com-

promises the properties of the refrigerant

being added to the rooftop unit and results

in substandard performance of the unit.

Checking Superheat and Subcooling

R-410A temperature charts list the associated satura-

tion temperature in one column and the associated pres-

sure in another column. See Table 25 on page 40.

Subcooling

When the refrigerant charge is correct, there is no va-

por in the liquid sight glass with the system operating

under full load conditions.

The subcooling temperature of each system can be

calculated:

1. Record the temperature of the liquid line at the

outlet of the condenser.

2. Subtract it from the saturation temperature listed in

Table 25 for the corresponding discharge pressure.

3. If the rooftop unit lacks an access port for liquid ac-

cess, subtract the condenser coil pressure drop value

from Table 25 from the discharge pressure to deter-

mine the equivalent saturation temperature.

For example, when the discharge pressure is 388 psig

and the liquid line temperature is 95.0°F:

• Liquid Pressure = Discharge Pressure (388 psig)

minus 33 psig = 355 psig

• Saturation Temperature for 355 psig = 108.0°F

Start the unit and check the rotation of fans and com-

pressors. Scroll compressors only compress in one

rotational direction. Refer to the Startup and Perfor-

mance Checklist (Form 145.13-CL1).

Prior to startup, it is important to ensure

proper compressor and fan rotation di-

rection is achieved when the system is

installed and operated.

To ensure proper unit operation, monitor the microproces-

sor board for any fault codes. Verify the proper compres-

sor direction by observing that, when the compressor

energizes, the refrigerant suction pressure drops and

the refrigerant discharge pressure rises. Reverse com-

pressor rotation also results in an elevated sound level

and a substantially reduced current draw. Both refriger-

ant pressures are close to equal pressure.

Ensure evaporator motor rotation is cor-

rect upon unit start-up. Switch any two

wires at contactor if blower rotation is

not correct.

If opposite rotation is noticed, disconnect and reverse

any two leads of the three phase supply. Reconnect the

power. If one component is operating in the wrong di-

rection, then all other three phase components on the

unit may be operating in the same phase.

Observe unit operation and check for

unusual noise or vibration.

The air conditioning section of this

equipment is charged with R-410A, a high

pressure refrigerant. Only qualied techni-

cians, using appropriately pressure rated

test instruments, should perform trouble-

shooting or service on this equipment.

TABLE 23 - PRESSURE SWITCH SETTINGS – ALL

MODELS

HIGH LOW

Cut Out (psig) 600 68

Cut In (psig) 450 107

Loading...

Loading...