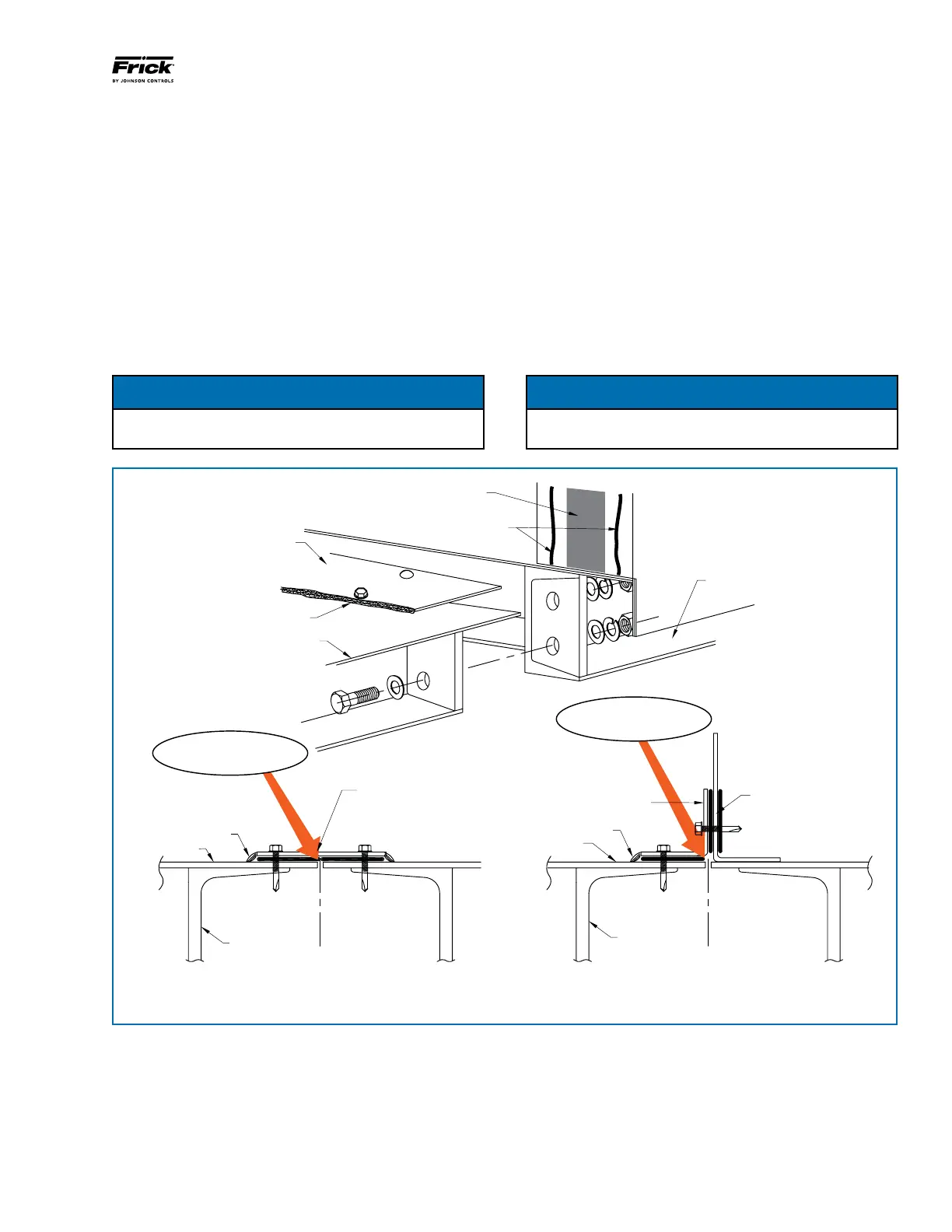

When two AcuAir unit sections are drawn together the base

channels of the two sections form an uninsulated cavity that

under certain conditions could produce condensation. AcuAir

provides a ship loose foam insulation kit to ll this cavity as

part of the reconnect procedure.

The insulation may be injected either from the top of the

cavity prior to installing the reconnect split cover strip, or

from underneath the unit provided the reconnect joint is not

positioned directly over a support structure cross member.

BASE CHANNEL

SPLIT COVER

BASE SKIN

CAULK EDGE OF COVER

AFTER ANCHORING

CAULK

CAULK

BASE SKIN

BASE CHANNEL

INTERNAL WALL

C

L

SPLIT

GASKET

SPLIT COVER

SIDE VIEW WHEN INTERNAL WALL

IS AT A SPLIT.

SPLIT COVER

CAULK

BASE SKIN

BASE CHANNEL

C

L

SPLIT

TYPICAL JOINT OF TWO SECTIONS

WITH FLAT SURFACES

Inject Foam Prior to

Installing Cover

Inject Foam Prior to

Installing Cover

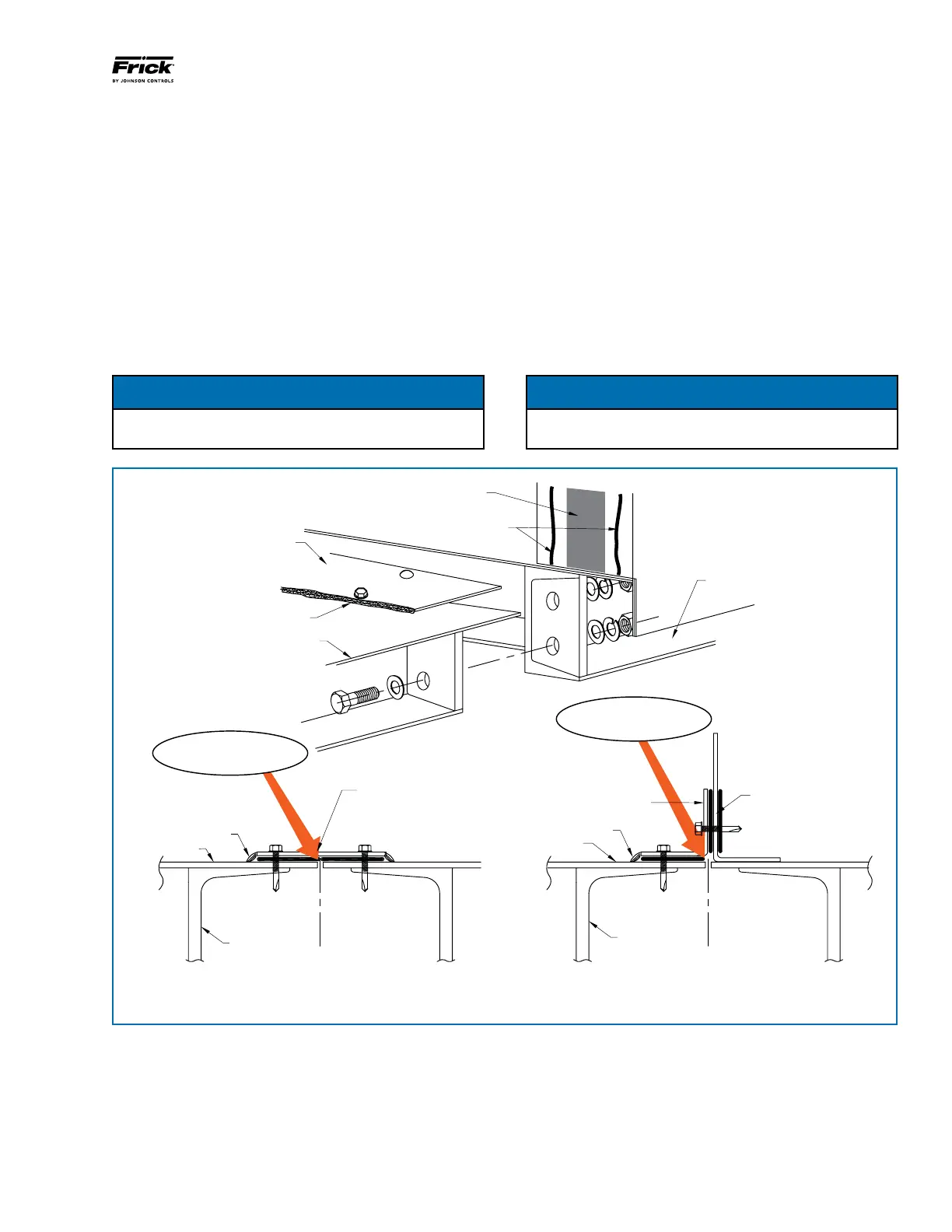

Follow the instructions provided by the foam manufacturer

for preparing the two part foam mixture and the injection kit.

Take special note of the 30 second inactivity limit after which

the injection nozzle may become permanently clogged.

Foam should be injected into the cavity at a rate of 3-4 brd-

ft per linear foot of seam. This will mean a 15 brd-ft can of

expanding foam will ll between 4-5 linear feet of AcuAir

reconnect seam.

When lling the reconnect seam from the top (inside the

AcuAir unit), it may be advisable to cover the bottom of the

opening with duct tape to prevent the foam from dropping

out before it has a chance to expand and attach itself to the

cavity walls.

Loading...

Loading...