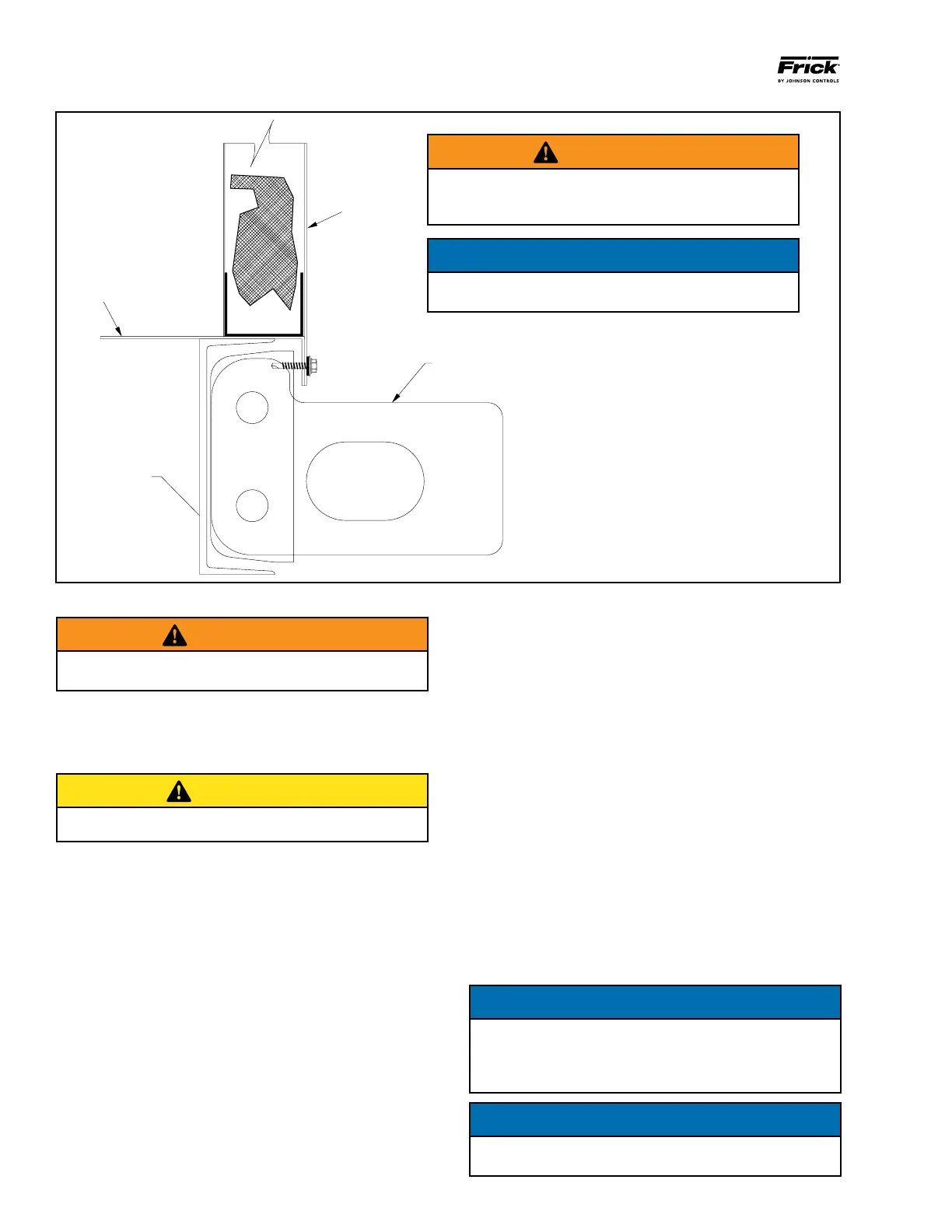

LD07923A

HOUSING

BASE SKIN

LIFTING LUG

PERIMETER

CHANNEL

Do not lift non-base units or subassemblies by attaching clevis,

hooks, pins, bolts, etc. to casing, casing hardware, angles, tabs

or anges.

Lift the air unit only in an upright

position. Never lift or move a unit on its side or upside-down.

AcuAir

®

systems may be shipped in two or more sections.

These sections must be anchored to a suitable support

structure - concrete pads, concrete piers, or structural steel,

capable of supporting the total system operating weight plus a

signicant safety margin as determined by a qualied structural

engineer. The weight the support structure must support and

the anchoring requirements will vary with live loads (expected

snow/ice buildup) seismic, and wind loading. See Figures 6

and 7 for AcuAir unit support methods.

If the support structure is in the form of two or more parallel

steel beams, the beams should be sized in accordance with

standard engineering practices. The structure must be capable

of supporting the shipping weight of the unit as provided on

the order related documents. In addition it must also be able

to carry any operating-duty-related loads such as: water

or refrigerant within the cooling and heating coils; possible

frost on the cooling coils; any applicable ooded refrigerant

surge vessel and associated piping; snow loads that could

accumulate on the roof; horizontal wind loads; etc.

It is recommended that the structure be designed for at least

110% of the operating weight of the system distributed as

a uniform load over the longitudinal beams, allowing for a

maximum deection of 1/360 of the length, not to exceed 1/2".

The support structure, whether concrete pads, concrete piers,

or structural steel, on which the units are to be located should

be rigid and level (shim if required).

Shims should be placed at intervals no greater than 5 feet apart

and should not be used to compensate for signicant surface

slope. The sum total of any individual stack of shims should

not exceed ½” and are to be used to compensate for surface

irregularities only. On units more than 150 inches wide the

foundation shall support not only the perimeter base channel,

but also the midpoint of each unit split. (Reference Figure 6)

Consult factory if housekeeping pad is not continuous.

The AcuAir unit must be secured to the Support structure. It

is the installer’s responsibility to be sure the unit is secured

in accordance with applicable building and earthquake codes.

Loading...

Loading...