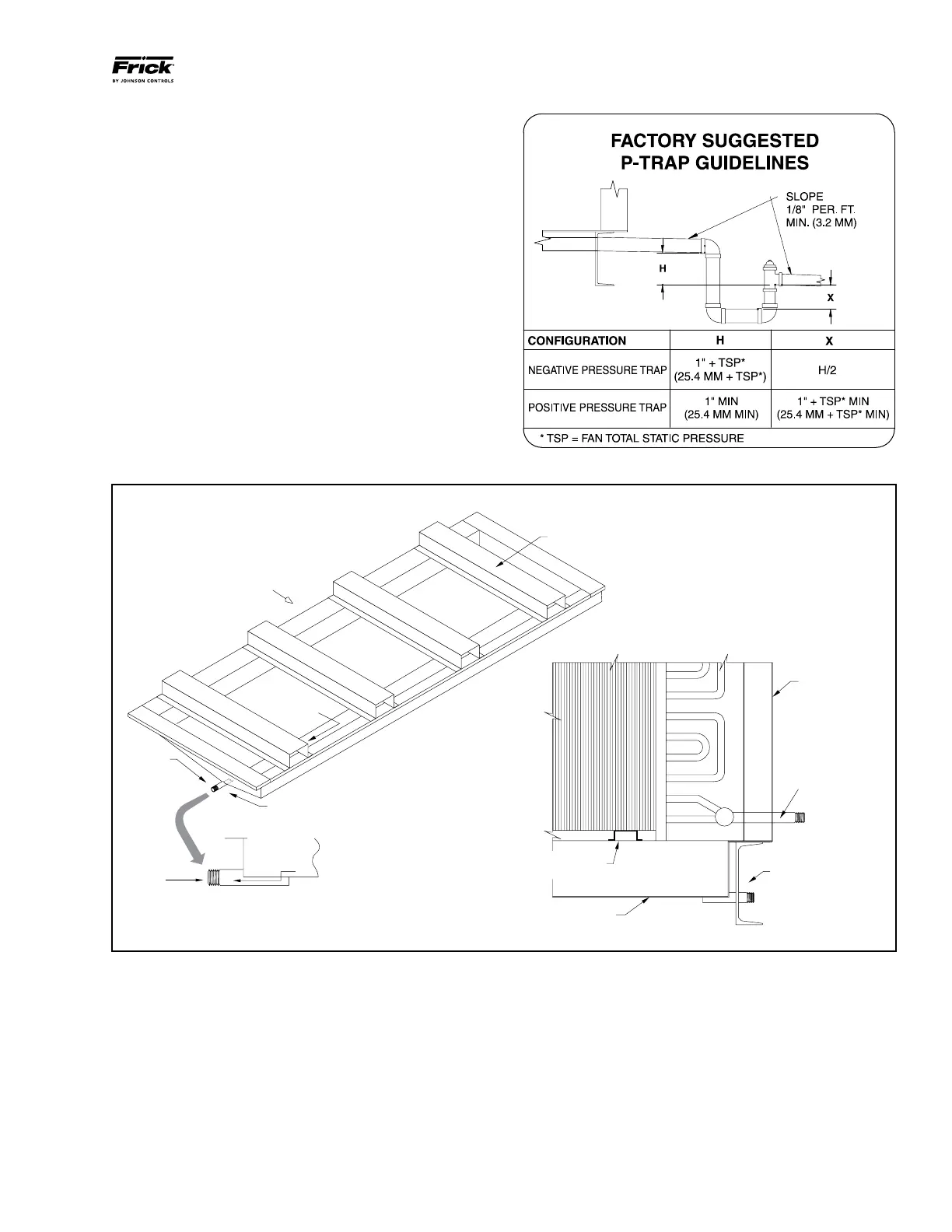

All condensate drain connections and oor drains must be

trapped at the job site location. Failure to properly trap a drain

will result in ooding of the drain pan and potential water

damage to the air-handling unit and other building facilities.

To design the drain traps, reference Figure 28 as well as the

total static pressure (TSP) associated with the main fan and

motor as indicated on the applicable AcuAir data drawing.

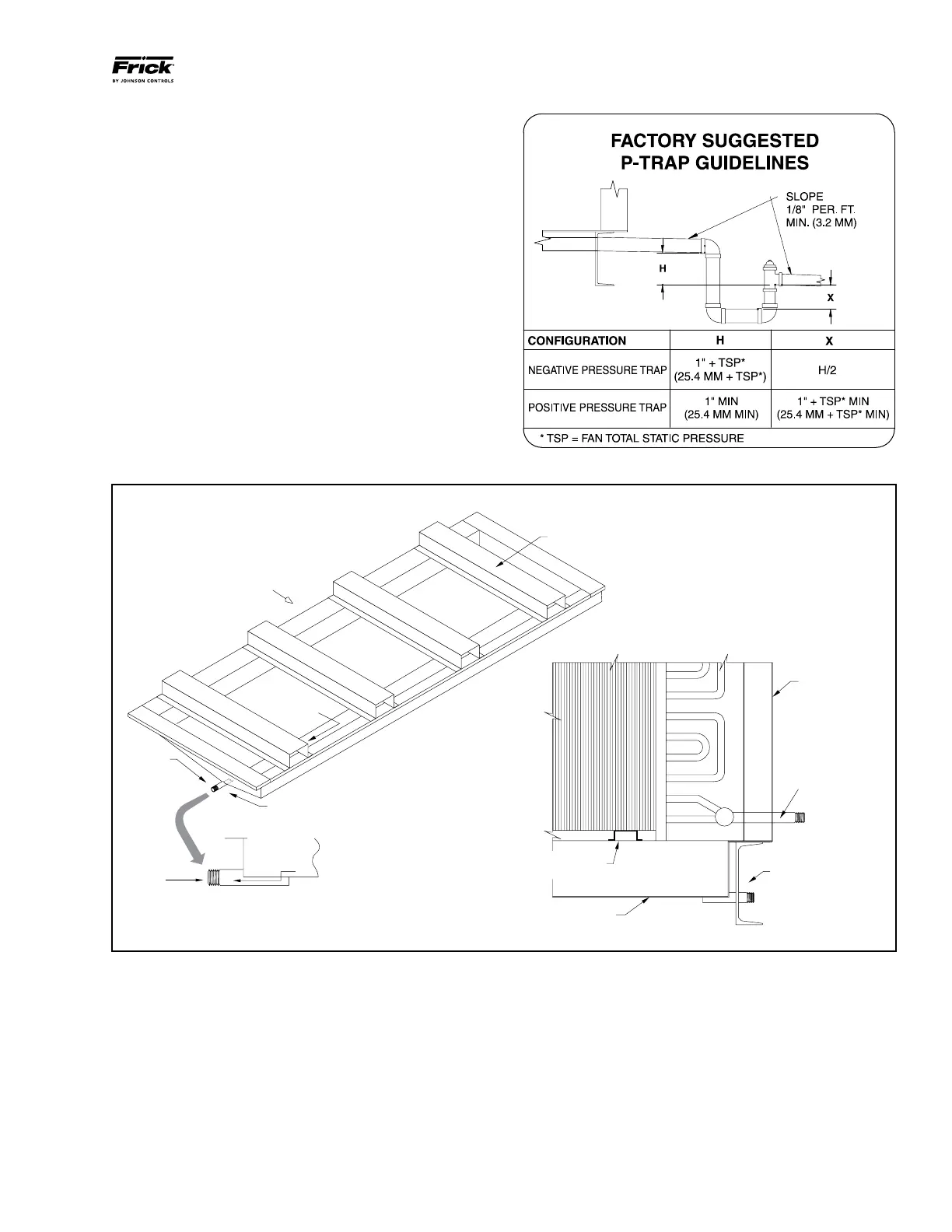

AcuAir recessed hygienic drain pans are triple sloping and

have a minimum depth of 3” at the drain connection. Drain

pans and pipe stub outlet connection are constructed of 304

stainless steel unless specied otherwise. The cooling coil

supports are constructed of material similar to the air unit

interior liner and may not be stainless steel.

SLOPE

RECESSED HYGIENIC OUTLET

SLOPE

MPT

SLOPE

AIRFLOW

ACUAIR UNIT

HOUSING

REFRIGERANT

CONNECTION

STUB DRAIN

DRAIN PAN

HOT CHANNEL

COIL SUPPORT

COIL SUPPORTS

– Every effort must be made in eld piping to keep

the stresses to a minimum on the coil connections.

a. Allow for thermal expansion and contraction of all eld

piping.

b. Do not rely on the coil connections to support the weight

of the eld piping.

c. Design piping to minimize transmittal of vibration through

the piping to the unit coils.

– When a steam coil is supplied, the steam

piping must be installed in accordance with state and local

codes and accepted industry practices. Please refer to the

supplied piping diagram for specic information.

Prior to shipment, steam coils are pressure tested for a

maximum operating pressure of 150 PSI. It is recommended

that the steam pressure be reduced to 15-50 PSI or lower

for maximum steam coil life and optimum control operation.

Loading...

Loading...