System 450™ Series Control Module with Ethernet Communications Installation Instructions 11

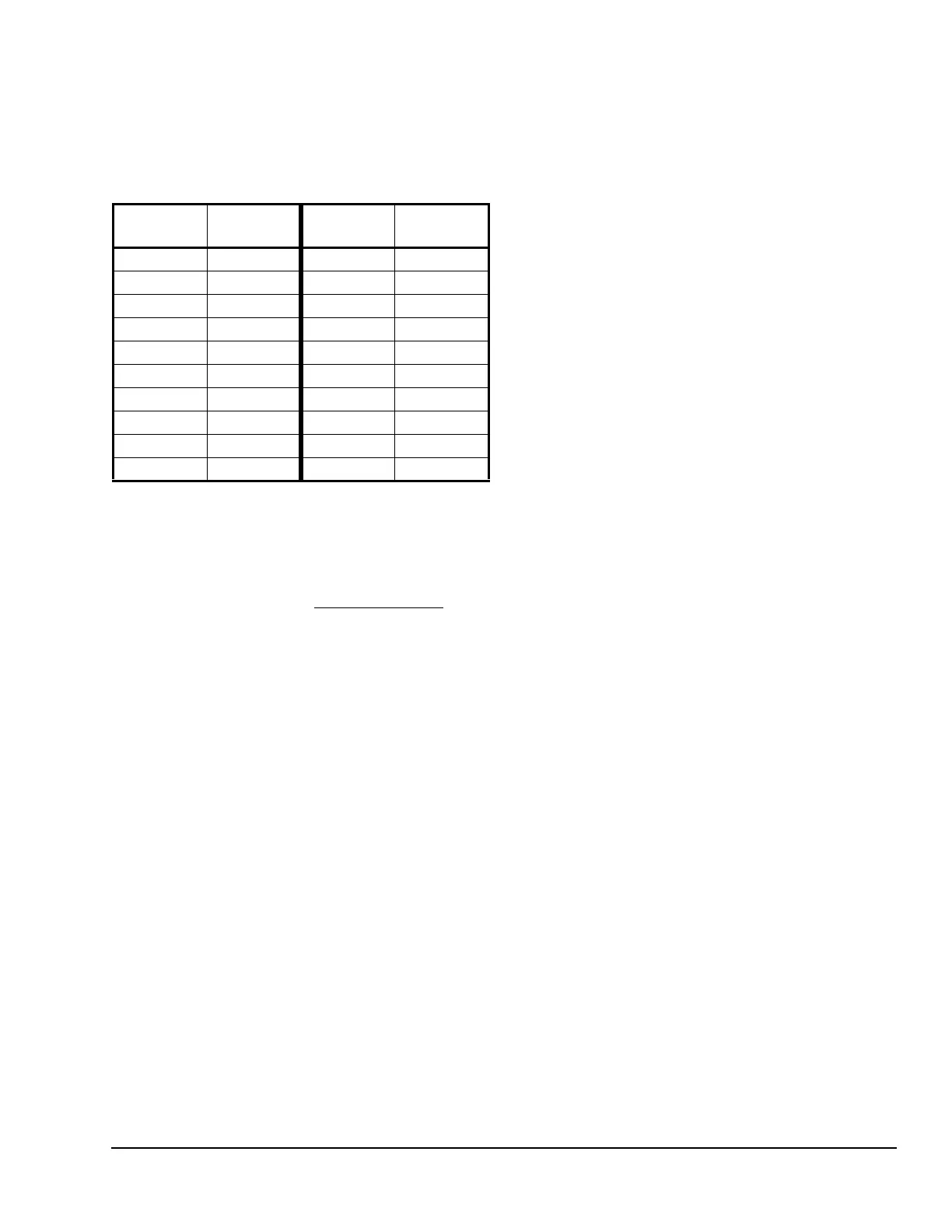

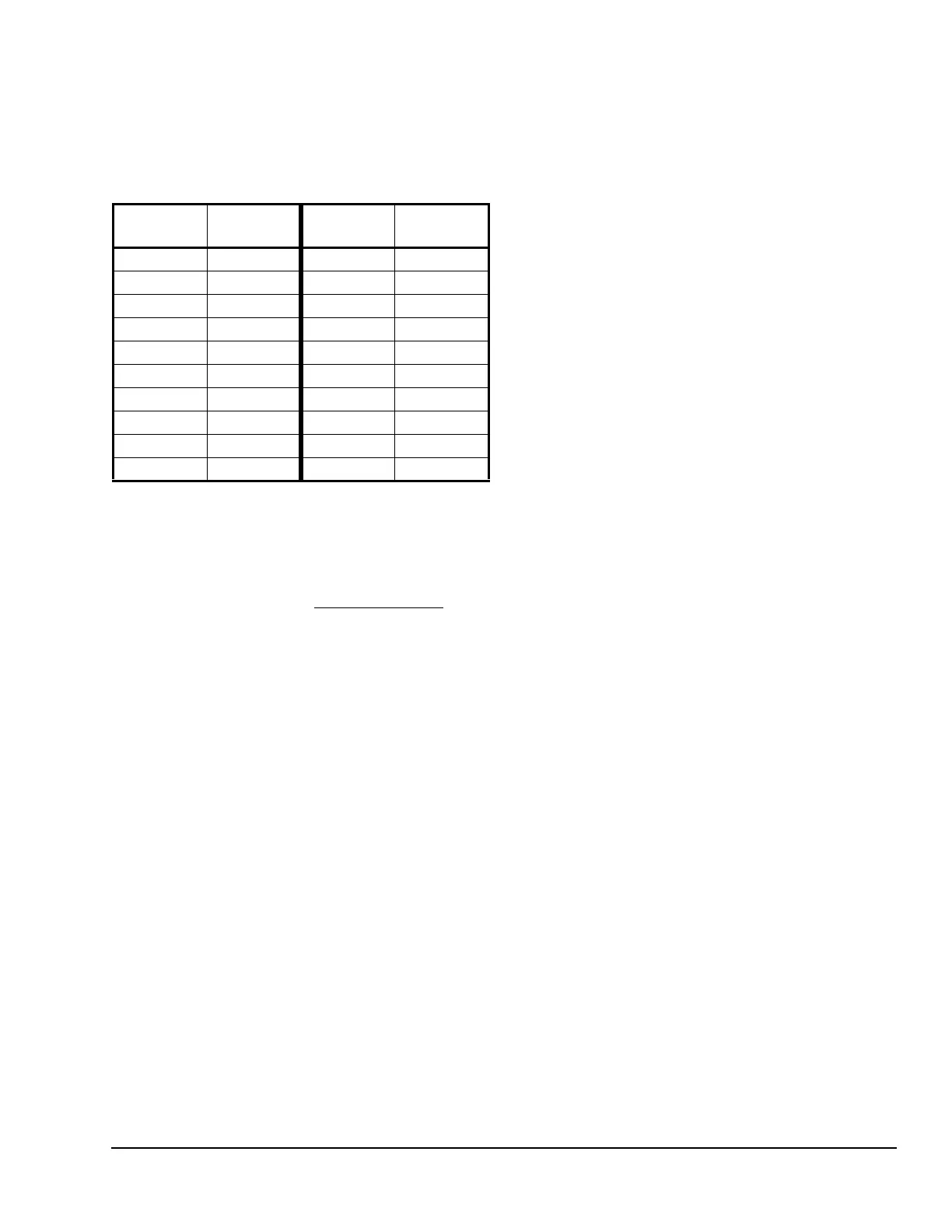

Use Table 5 to determine the negative PSI setup value

that corresponds to your InHg target value. For

example, if you want a relay output to go off when the

sensed pressure reaches 7 InHg, you select the value

-3.5 (psi) in the output’s Relay OFF Selection screen.

Note: When an output references the P 110 Sensor

Type and the output is set up for Differential Control

(Sn-1 and Sn-2 are P 110 Sensor Type), the negative

pressure values displayed in the differential pressure

System Status screen (dIFP) appear as negative psi

values, not InHg values. See Differential Control

for

more information.

Binary Input Control for Relay Outputs

You can connect a binary input (dry contacts) to any of

the three System 450 communications control module

inputs (Sn1, Sn2, or Sn3) and control the output relays

in your control system based on the binary input’s state

(open or closed).

A sensor (Sn-1, Sn-2, or Sn-3) set up as a binary input

can only be referenced by a relay output. Sensors set

up as binary inputs are not available for selection on

analog outputs.

When a relay output references a sensor that is set up

as a binary input, the On and OFF parameter screens

are not available as you set up the output. The relay

output’s On/Off state is controlled by the binary input’s

Closed/Open state and any of the timer parameters

(ONT, OFFT, ONd, or OFFd) that you set up for the

relay output. Refer to the Binary Input Control for Relay

Outputs section on page18 of the System 450 Series

Modular Control Systems with Communications

Control Modules Technical Bulletin (LIT-12011826) for

more information.

High Input-Signal Selection

System 450 control modules with communications

include the High Input-Signal Selection control feature.

The High Input-Signal Selection feature enables a

System 450 control system to monitor a condition

(temperature, pressure, or humidity) with two or three

sensors (of the same type) and control relay and/or

analog outputs based on the highest condition value

sensed by the two or three referenced sensors.

In two sensor applications (HI-2), Sn-1 and Sn-2 must

be the same Sensor Type. In three sensor applications

(HI-3), Sn-1, Sn-2, and Sn-3 must be the same Sensor

Type.

A System 450 control system, using High Input-Signal

Selection, can monitor the outlet pressures of two

condenser coils in a multi-circuit condensing unit using

two pressure sensors of the same type; one connected

to each coil outlet.

Differential Control

System 450 control modules with communications

include the Differential Control feature. Differential

control is used to monitor and maintain a given

difference in a condition (temperature, pressure, or

humidity) between two sensor points within a system,

process, or space.

The Differential Control feature enables a System 450

control system to monitor the temperature, pressure, or

humidity differential between two sensors of the same

type (Sn-1 and Sn-2) and control relay and/or analog

outputs based on the sensed differential value relative

to user-selected differential values (dON, dOFF, dSP,

and dEP).

When a Differential Control sensor (Sn-d) is set up, the

displayed differential sensor value is a calculated

variable value: (Sn-d) = (Sn-1) – (Sn-2).

The Sn-d value appears in the System Status screens

as either a temperature differential value (dIFT),

pressure differential value (dIFP), or humidity

differential value (dIFH). The unit of measurement

associated with the displayed differential value is

determined by the Sn-1 and Sn-2 Sensor Type. See

Table 3 on page 8 for Sensor Types and their units of

measurement.

The relay output setup values dON and dOFF are

condition differential values. When a relay output is set

up for differential control, System 450 controls the relay

state (On or Off) based on the difference between Sn-1

and Sn-2 (Sn-d) relative to the user-selected

differential On (dON) and differential Off (dOFF)

values.

Table 5: InHg Target Values and PSI Setup Values

InHg

Value

psi Setup

Value

InHg

Value

psi Setup

Value

1 -0.5 11 -5.5

2 -1.0 12 -6.0

3 -1.5 13 -6.5

4 -2.0 14 -7.0

5 -2.5 15 -7.5

6 -3.0 16 -8.0

7 -3.5 17 -8.5

8 -4.0 18 -9.0

9 -4.5 19 -9.5

10 -5.0 20 -10.0

Loading...

Loading...