JOHNSON CONTROLS

27

FORM 160.75-O1 (211)

SECTION 6 - MAINTENANCE

RENEWAL PARTS

For any required Renewal Parts, refer to the Renewal

Parts – Unit (Form 160.75-RP1).

CHECKING SYSTEM FOR LEAKS

Leak Testing During Operation

The refrigerant side of the system is carefully pressure

tested and evacuated at the factory.

After the system has been charged, the system should

be carefully leak tested with a R-134a compatible leak

detector to be sure all joints are tight.

If any leaks are indicated, they must be repaired im-

mediately. Usually, leaks can be stopped by tighten-

ing flare nuts or flange bolts. However, for any major

repair, the refrigerant charge must be removed. (Refer

to Handling Refrigerant For Dismantling And Repairs

on Page 30)

CONDUCTING R-22 PRESSURE TEST

With the R-134a charge removed and all known leaks

repaired, the system should be charged with a small

amount of R-22 mixed with dry nitrogen so that a ha-

lide torch or electronic leak detector can be used to de-

tect any leaks too small to be found by the soap test.

To test with R-22, proceed as follows:

1. With no pressure in the system, charge R-22 gas

into the system through the charging valve to a

pressure of 2 PSIG (14 kPa).

2. Build up the system pressure with dry nitrogen to

approximately 75 to 100 PSIG (517 to 690 kPa).

To be sure that the concentration of refrigerant has

reached all part of the system, slightly open the oil

charging valve and test for the presence of refrig-

erant with a leak detector.

3. Test around each joint and factory weld. It is im-

portant that this test be thoroughly and carefully

done, spending as much time as necessary and us-

ing a good leak detector.

4. To check for refrigerant leaks in the evaporator

and condenser, open the vents in the evaporator

and condenser heads and test for the presence of

refrigerant. If no refrigerant is present, the tubes

and tube sheets may be considered tight. If refrig-

erant is detected at the vents, the heads must be

removed, the leak located (by means of soap test

or leak detector) and repaired.

6

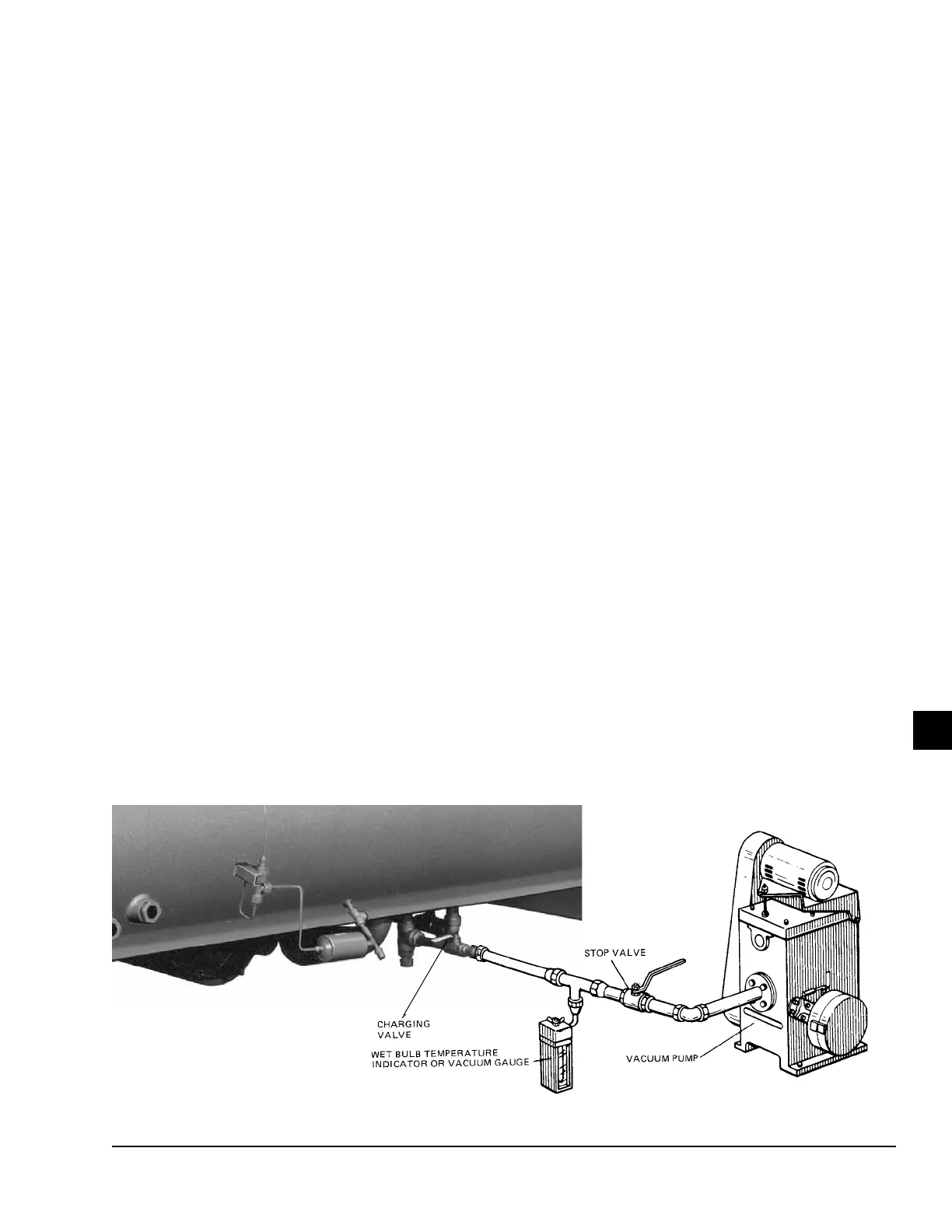

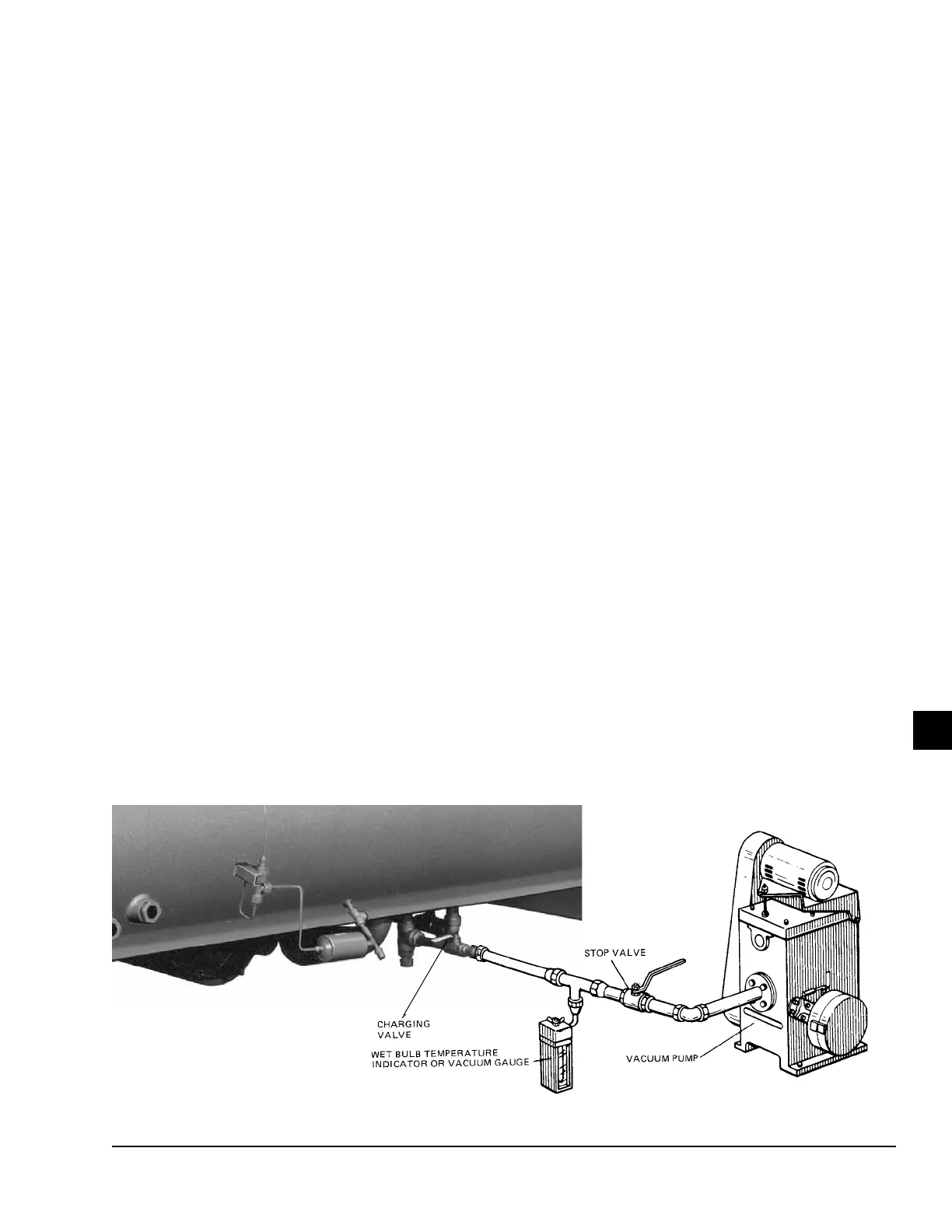

EVACUATION AND DEHYDRATION OF UNIT

FIGURE 14 - EVACUATION OF CHILLER

27385A(D)

LD00949

Loading...

Loading...