JOHNSON CONTROLS

35

FORM 160.75-O1 (211)

SECTION 7 - PREVENTIVE MAINTENANCE

It is the responsibility of the owner to provide the nec-

essary daily, monthly and yearly maintenance require-

ments of the system.

IMPORTANT – If a unit failure occurs

due to improper maintenance during the

warranty period; Johnson Controls will

not be liable for costs incurred to return

the system to satisfactory operation.

In any operating system it is most important to pro-

vide a planned maintenance and inspection of its func-

tioning parts to keep it operating at its peak efficiency.

Therefore, the following maintenance should be per-

formed when prescribed.

COMPRESSOR

1. Oil Filter – When oil pump VSD frequency in-

creases to 55 hz to maintain target oil pressure.

When the oil filter is changed, it should be inspect-

ed thoroughly for any aluminum particles which

would indicate possible bearing wear. If alumi-

num particles are found this should be brought

to the attention of the nearest Johnson Controls

office for their further investigation and recom-

mendations.

2. Oil Changing – The oil in the compressor must

be changed annually or earlier if it becomes dark

or cloudy. However, quarterly oil analysis can

eliminate the need for an annual change provided

the analysis indicates there is no problem with the

oil.

COMPRESSOR MOTOR

1. Check motor mounting screws frequently to in-

sure tightness.

2. Meg motor windings annually to check for dete-

rioration of windings.

GREASED BEARINGS

Motor Operation and Maintenance manuals are sup-

plied with the chillers providing maintenance sched-

ules and instructions for the specific motors. The fol-

lowing are lubrication schedules for the most common

motors:

RAM Motor Lubrication

Frame 143T thru 256T are furnished with double

sealed ball bearings, pre-lubricated prior to installa-

tion. Grease fittings are not supplied and bearings are

designed for long life under standard conditions.

Frames 284T thru 587UZ are furnished with double

shielded or open ball or roller bearings. It is necessary

to re-lubricate anti-friction bearings periodically. (Re-

fer to Table 3 on Page 35.)

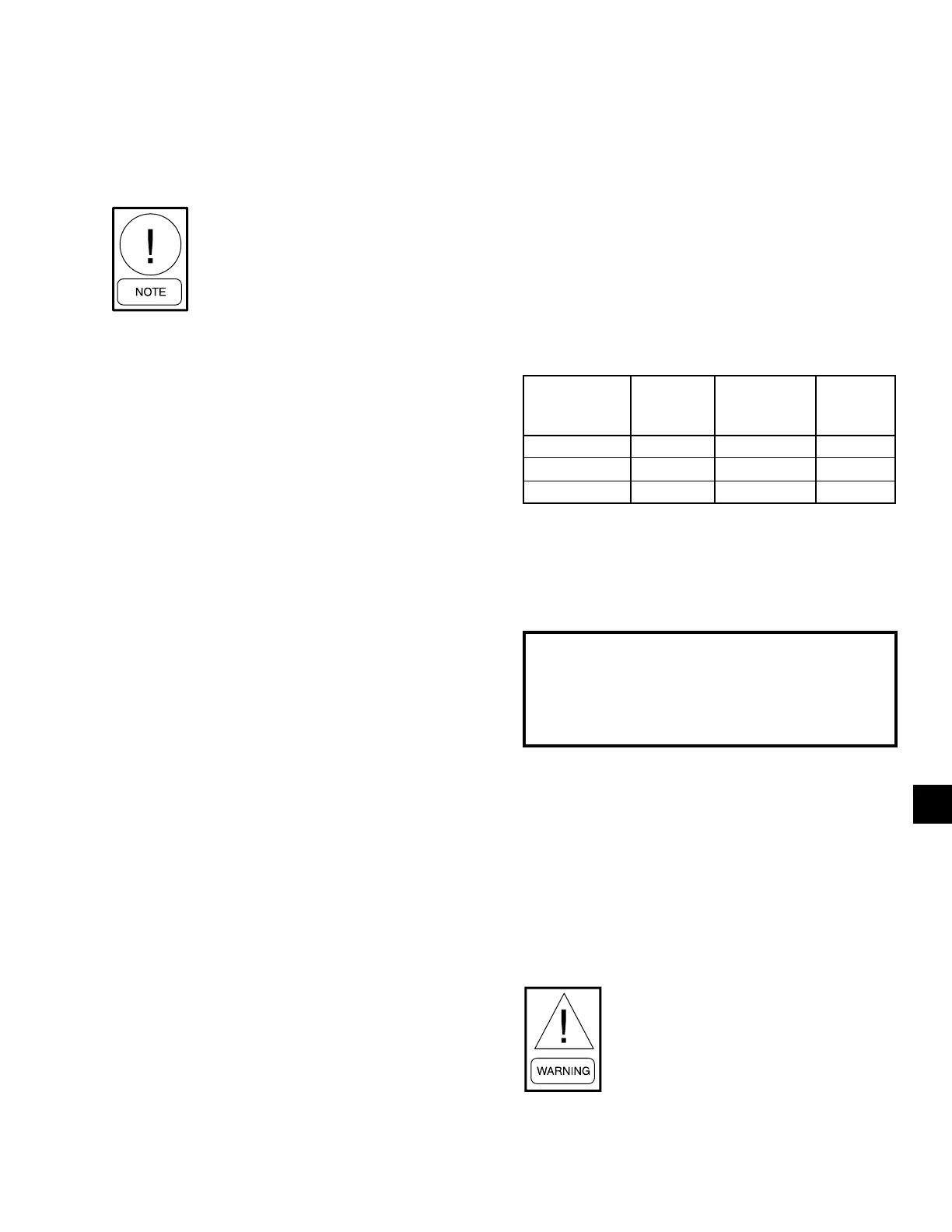

TABLE 3 - BEARING LUBRICATION

FRAME

SIZE

STANDARD

8HR/DAY

CONTINUOUS

24HR DAY

GREASE

QUANTITY

OZ.

143T-256T *7 Years *3 Years *1

284TS-286TS 210 Days 70 Days 1

324TS-587USS 150 Days 50 Days 2

* On frame sizes 143T - 256T, changing bearings at these

intervals is recommended. However, removing the seal, clean-

ing and relling the bearing and the cavity with recommended

grease can re-lubricate these bearings.

Recommended greases for standard applications:

OPERATING AMBIENT TEMP. -30ºC to 50ºC

Chevron SRI (Chevron)

Exxon Unirex #2 (Exxon Corp.)

Exxon Polyrex (Exxon Corp.)

Shell Dolum R (Shell Oil Co.)

Westinghouse Motor Lubrication:

• Re-greasing should occur at 1000 operating hour

intervals.

• Westinghouse recommends using Westinghouse

Grease No. 53701.

• Motors with shaft diameters less than 2 3/8 inch

require 1 oz of grease per bearing while motors

with shaft diameters between 2 3/8 and 3 inches

require 1.5 oz.

Mixing different greases is not recom-

mended

7

Loading...

Loading...