THESE ITEMS HAVE BEEN SPECIFICALLY DESIGNED FOR LO-NOISE EMISSIONS AND FITTING

OF ALTERNATIVE ITEMS COULD CAUSE AN INCREASE IN THE OPERATIONAL NOISE OF THE

MACHINE.

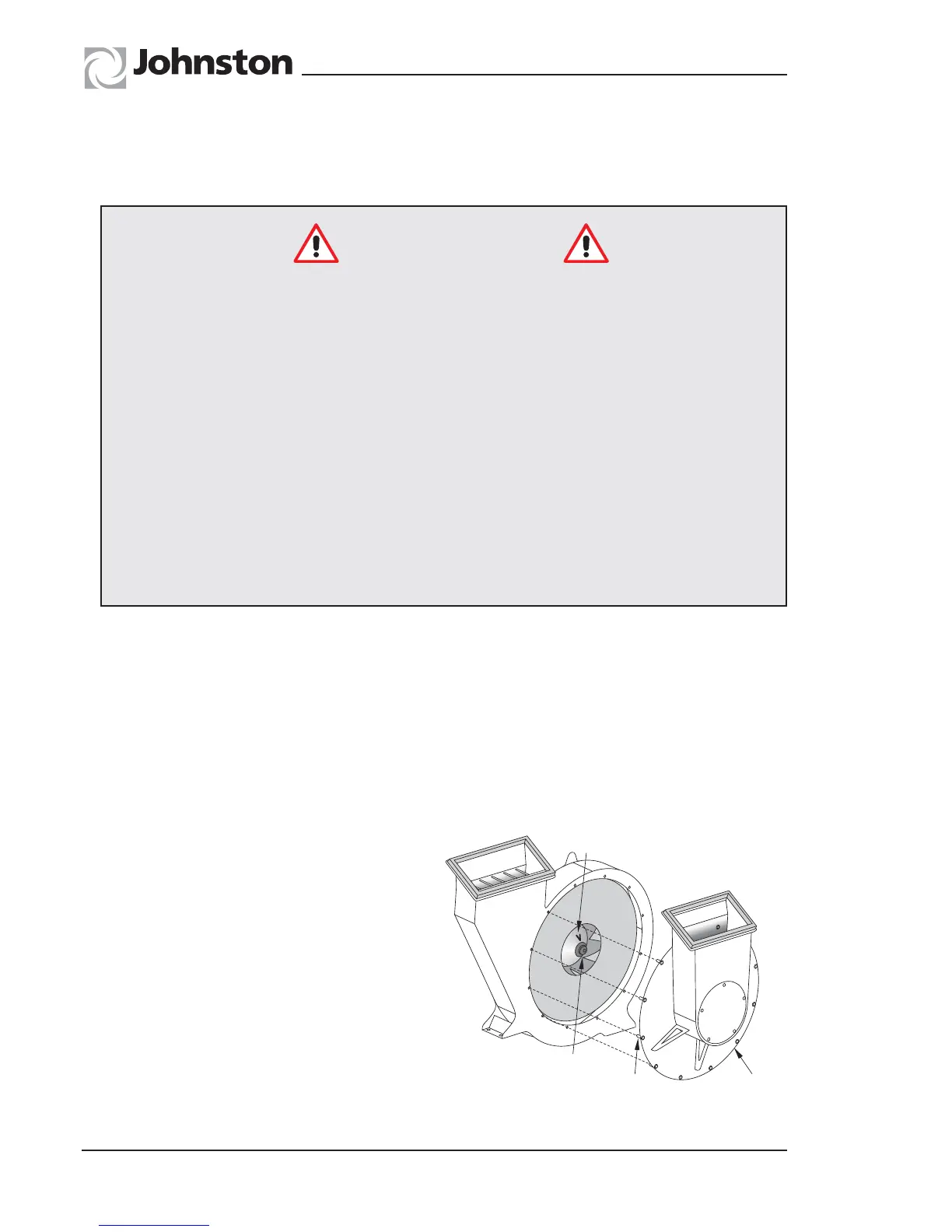

FAN IMPELLER

INSPECTION -This should be on a regular basis as outlined in the routine maintenance. The impeller

should be replaced as soon as the blade thickness is less than 2mm or the blades have visible signs of

wear/damage.

REMOVAL

1. Raise the body and ensure the body prop is

engaged in the rack.

2. Isolate the battery.

3. Remove the 12 bolts (A) holding on the fan

cover and remove cover (B).

4. Remove the capscrew (C) in the centre of the

fan.

5. The fan impeller should slide off the shaft, a

bearing puller 437-2 can be used if required.

Page Issue 01Chapter - Wearing Items12:2

VT551 - Maintenance

WEARING PARTS REPLACEMENT INSTRUCTIONS

It is important that the following safety precautions are observed when working on the machines.

Ensure the machine is standing on firm, level ground and there are no obstructions above or

to the rear before raising the body.

Ensure the safety prop is engaged at all times when working under the body.

Ensure operators are fully conversant with the controls and operation.

Isolate the air in the systems locker before working on any pneumatically operated or

controlled equipment.

Disconnect or isolate the vehicle battery when working on the electrical system.

Do not approach the fan inlet while the fan is running.

Do not grasp any part of the engine or exhaust system without first ascertaining whether it

has cooled sufficiently to avoid scalding.

Be aware of the safety instructions relative to the suction fan given in the equipment

maintenance notes.

Keep hands, loose clothing, hair etc. well clear of moving parts.

Do not climb on the engine walkways unnecessarily or approach the fan inlet whilst the engine

is running.

Do not use ill-fitting tools such as spanners that may slip and cause injury.

Always get a second person to check periodically that all is well when only one person is

working on the machine or inside the body.

Safety Precautions

93MA. 015-2

(A)

(B)

(C)

(D)

Loading...

Loading...