Page Issue 01

Chapter - Wearing Items

12:3

VT551 - Maintenance

REFITTING

1. Replacement is the reverse of removal.

2. Lightly grease the fan motor spline using grease part number 94-24 before fitting the impeller.

3. Fit a new Tuflok capscrew and torque up to 101 Nm (75lbf. ft.).

4. Refit fan case cover with a suitable silicone sealant between the mating surfaces.

From July 2009 all impellers have a ‘’V’’ mark (D) at Top Dead Centre (TDC) applied when they are

manufactured. When fitting a replacement impeller it should be rotated so this mark is at the 12 o’clock

(TDC) position before the retaining bolt is tightened to the prescribed torque.

INTAKE DUCT FLAP

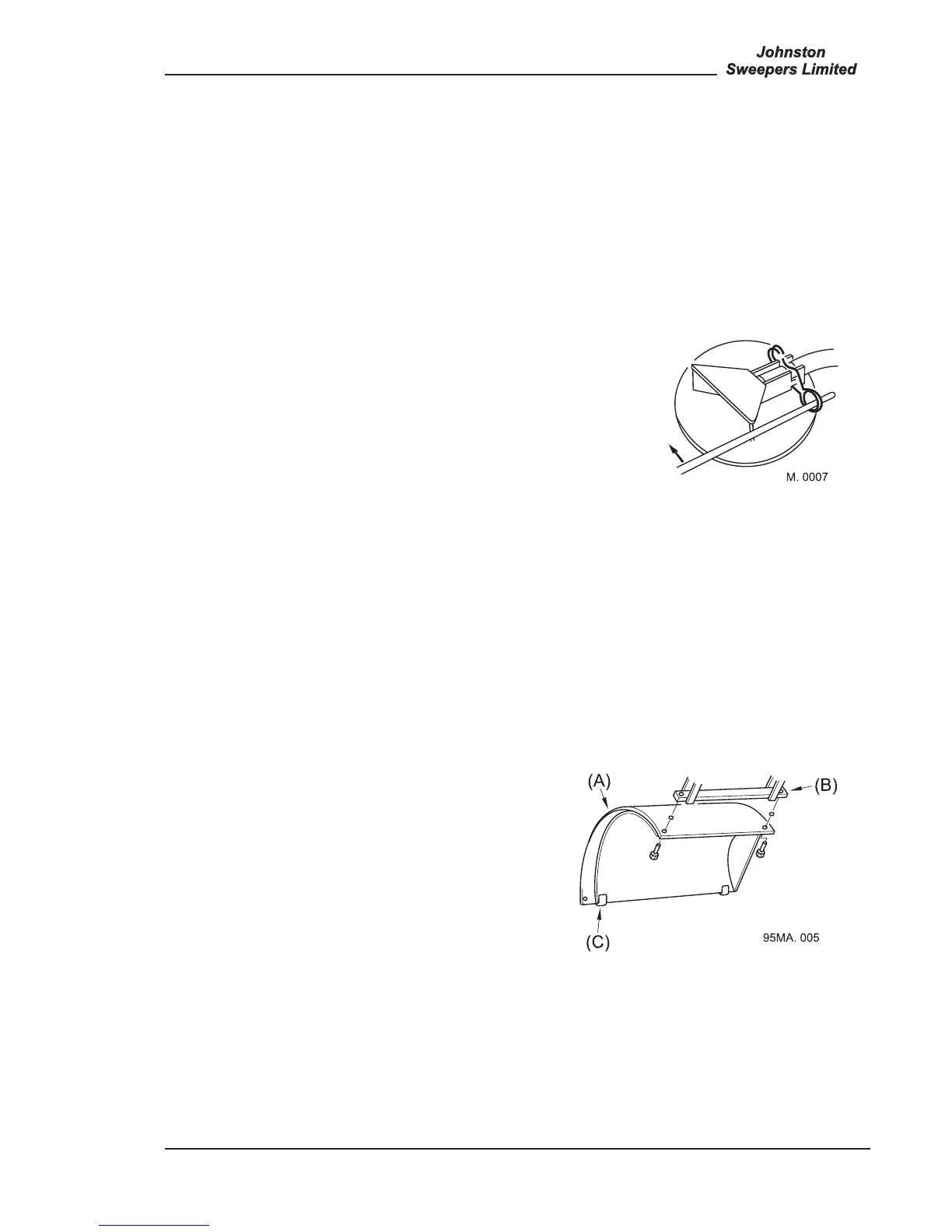

When the flap plate is in the open position, it is abraded by the material

discharging from the intake duct into the body. The flap should be

inspected periodically and replaced when worn. To inspect one must

first open the rear door and suitably prop open, then depressurise the air

system in the systems locker, this will allow the flap to be opened and

closed manually from the interior of the body. Enter body and inspect

the flap valve plate which is secured to actuating fingers by a pair of

spring clips.

REMOVAL

To remove a flap plate the springs must be withdrawn using a suitable tool or bar. Notice how the springs

were fitted from each side of the finger guide and around the groove in the finger assembly. Once the

springs are removed the flap plate can be detached from the finger.

REFITTING

Before refitting or fitting a new flap plate, ensure the springs are in good condition and the finger adjustment

areas have been cleaned, then locate flap on the finger and replace springs. Ensure the flap plate seats

correctly on top of the inlet tube, if not, check for excessive wear on the inlet tube/flap, or adjustment of

the flap operating mechanism.

WEAR PLATE

REMOVAL

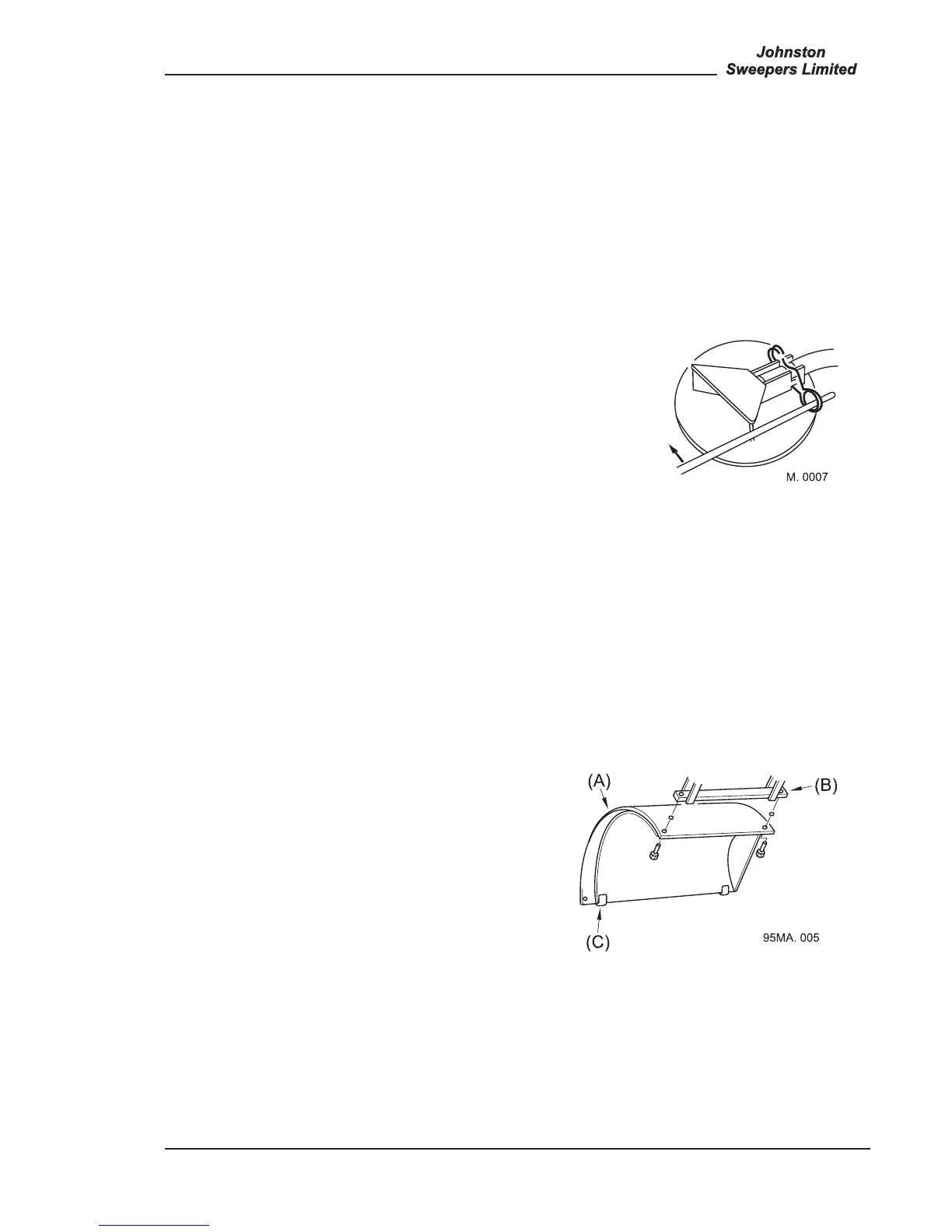

Enter the body after carrying out precautions as for intake

duct flap. The wear plate (A) is secured by two screws and

a clamp bar (B). It is a wise precaution to prop the wear

plate before attempting to remove these screws. Once the

screws are removed, support the wear plate and remove

the prop. Allow the wear plate to fall slightly and unhook

from the hooks (C) attached to the body outer skin, and

remove. Help may be required in removal as this unit weighs

approximately 36kg.

Loading...

Loading...