JPK Instruments NanoWizard

®

Handbook Version 2.2a

9

The mass of a cantilever strongly influences its resonant frequency and spring

constant. A light cantilever with a high spring constant will have high resonant

frequency. The higher the resonance frequency, the better the high spee

d

response of the cantilever in air.

For intermittent contact mode in liquid, the capillary force is not a problem, and

softer cantilevers are often used. “Contact mode” cantilevers are often used for

intermittent contact mode in

liquid conditions. The resonant frequencies are much

lower, and the damping of the liquid around the cantilever has a strong effect on

the resonance. The resonance of typical soft cantilevers in liquid is usually a few

kilohertz, but in fact the cantilev

er is often driven at a resonance of the liquid cell or

acoustic cavity in this frequency range rather than the actual cantilever resonance.

The spring constant of a cantilever can be estimated from its geometry and the

properties of the material it is m

ade from. The spring constant depends very

strongly on the thickness of the cantilever, however, and this can be difficult to

measure accurately. If a calibrated reference cantilever is available, then the

cantilevers can be pushed against one another to

compare the deflection of one

cantilever by the other. For soft cantilevers another option is to measure the

thermal noise and calculate the spring constant. This is an attractive option, since

the cantilever is not damaged by the measurement, and no ex

tra equipment is

required. These methods are discussed further in Section 4.5

2.5 Phase imaging

During an AFM experiment in intermittent contact mode the cantilever is driven at

some frequency in the kilohertz ra

nge (a few kHz in liquid, or a few hundred kHz in

air typically). The whole cantilever vibrates with the same frequency, but depending

on the condi

tions of the tip and sample there will be some phase shift between the

drive signal and the cantilever movement measured by the lock-in-

phase shift can be measured and displayed in a phase image.

The phase signal is sensitive to properties of the tip-

sample interaction, and may

show up mechanical information about the sample. Adhesion between th

e tip and

sample or other dissipation of the cantilever energy by a viscoelastic response of

the sample are two mechanisms that may cause a large phase shift of the

resonance. This means that sometimes in phase images two different components

embedded on

a topographically flat sample can be distinguished, as in the example

shown here.

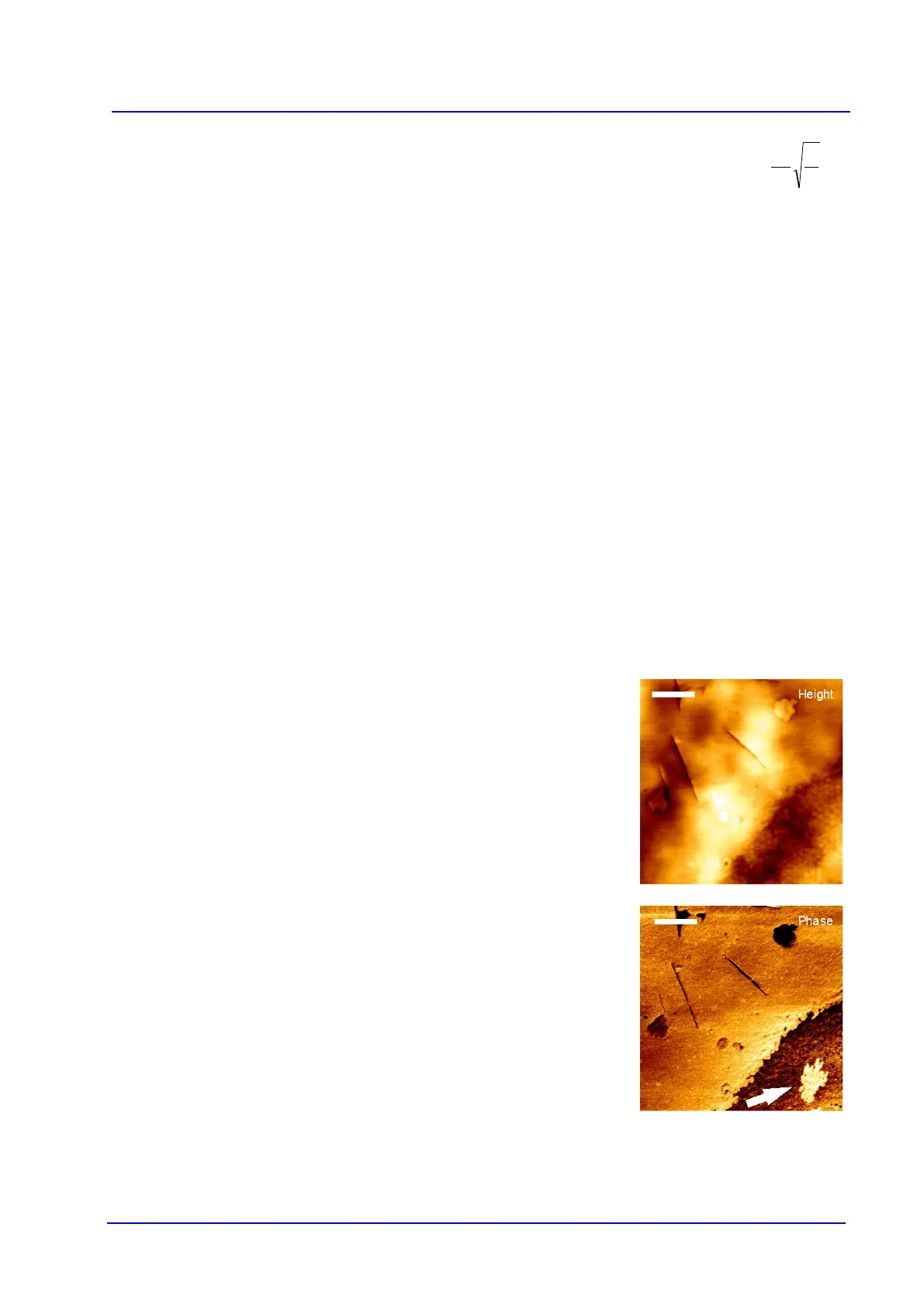

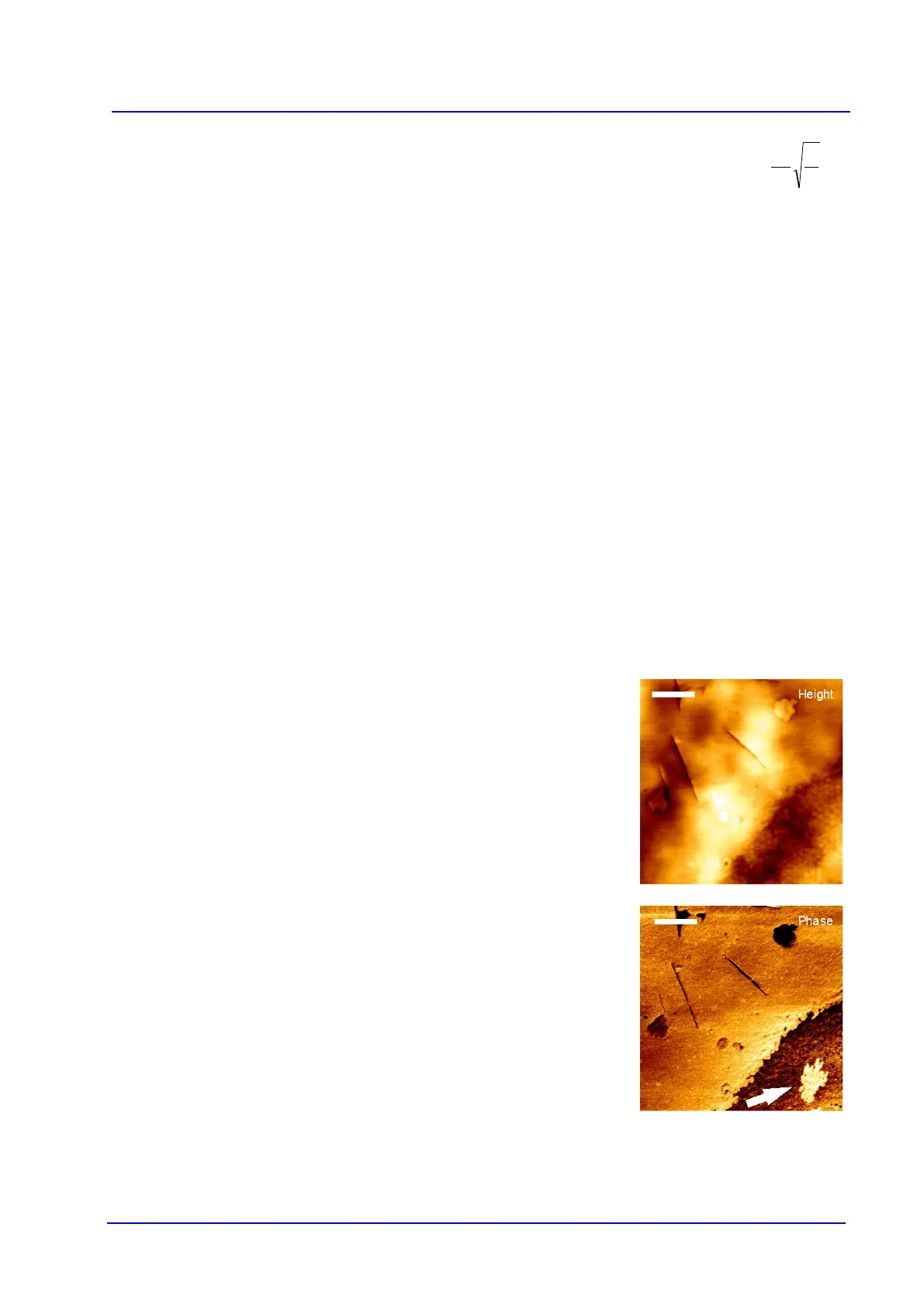

Height and phase images of the same area are shown, with the scale bar of 1

micron in each case. In the height image, there is an area in the lower right hand

corner where

the texture is different. The height changes smoothly, however, and

different regions can not be distinguished within it. In the phase image, there is a

sharp change of phase shift at the edge of the textured area, and there is a sharply

contrasting regi

on within it. This feature is marked with an arrow in the phase

image. This is typical of the case where material property differences show up in

the phase, independently of the height.

Loading...

Loading...