48

JPK Instruments NanoWizard

®

Handbook Version 2.2

Detergent treatment

Where biological material has adsorbed to the tip (for example after imaging living

cells or sticky protein aggregates), detergent treatment can be

useful to remove

material from the tip. Either a pure detergent can be used (for example, triton or

SDS), or a special mixture for cleaning cell culture glassware (e.g. Hellmanex, for

instance as a 2% solution). Often the best results are achieved by lea

ving the

cantilevers for a long time and heating. For example, leave the cantilevers

overnight at 40 or 50 ˚C in a petri dish on a hotplate.

Mild cleaning, particularly suitable for

biological contamination.

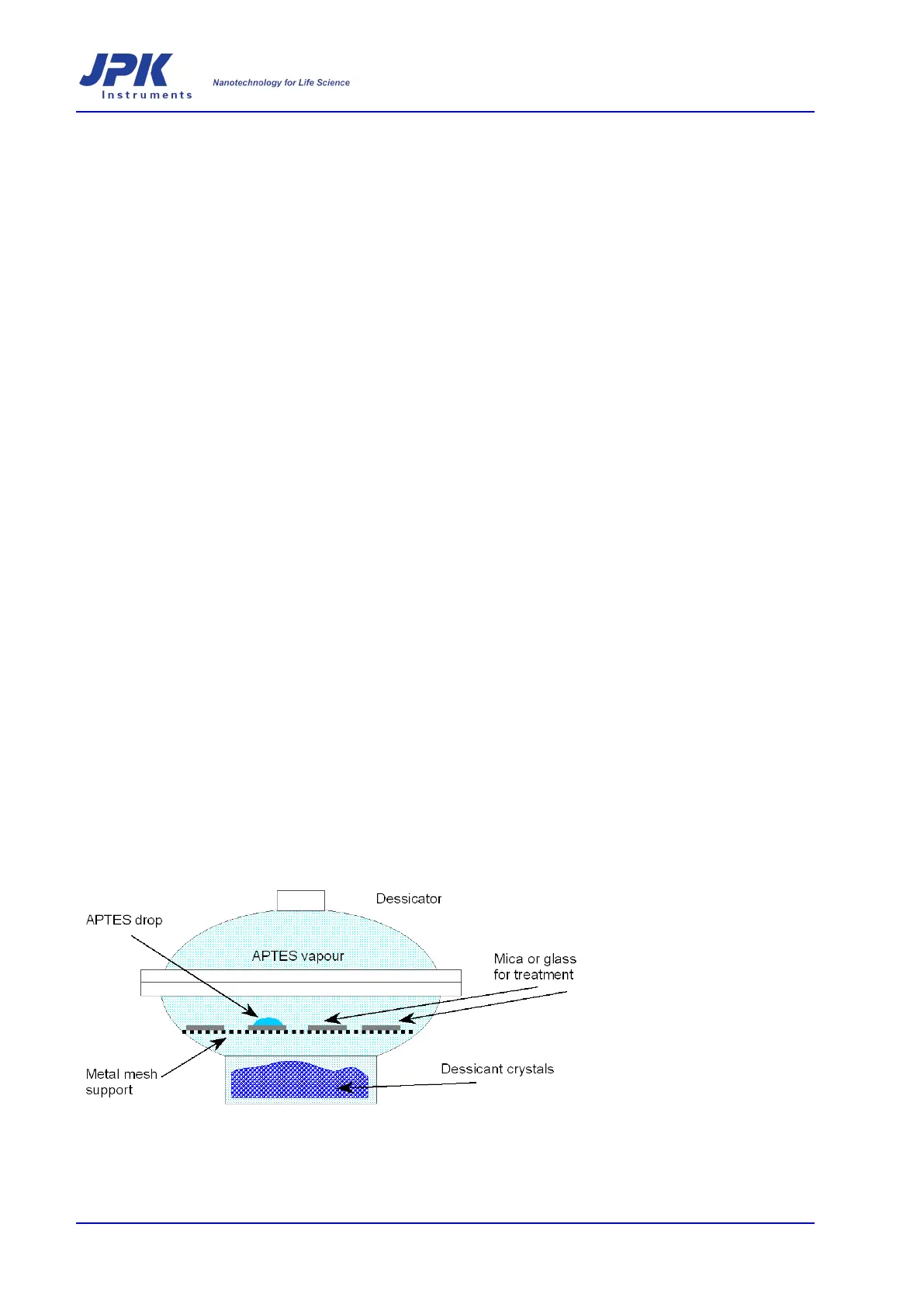

9.2 Silanization and APTES treatment

Silane treatment can be used to change the surface properties, different treatments

can be used on glass, mica, and also cantilevers . Either a solution or vapor

treatment can be used, the vapor method usually gives cleaner results.

Aminopropyltriethoxysilane (APTES) can be used to make the surface of glass or

mica both more hydrophobic and positively charged. After tre

will have amine –

NH2 groups that are positively charged in aqueous solutions. The

chemical needs to be high quality (high purity) or the surface contamination will be

larger than the proteins or other sample to be imaged. The chemical

is rather toxic,

so should generally be used in a fume cupboard.

The reaction should be done in small clean desiccator; this is the vapor

coating, so you need an enclosed space for the vapor

to react with the surface.

The dry conditions are i

mportant to prevent the APTES crosslinking to form large

aggregates. Freshly cleave several pieces of mica, or placed cleaned glass

coverslips on the metal mesh support in the desiccator

. Put one extra piece of mica

for the APTES liquid – note this must al

so be freshly cleaved! Place a droplet of

APTES on this mica. For a smallish (around 20 cm diameter) desiccator

, 20

microlitres APTES is enough.

Leave for around 2 hours to treat a freshly cleaved mica surface. The reaction is

rather faster with gla

ss, if coverslips are treated for example, clean them first and

try a treatment for 15-30 minutes.

At the end, the droplet of APTES will have turned into a whitish silicate solid, this is

not used, and the mica can be cleav

ed again to remove the reacted APTES. The

other pieces of mica should now have reacted with the vapor. The surface is best

Loading...

Loading...