–

82

–

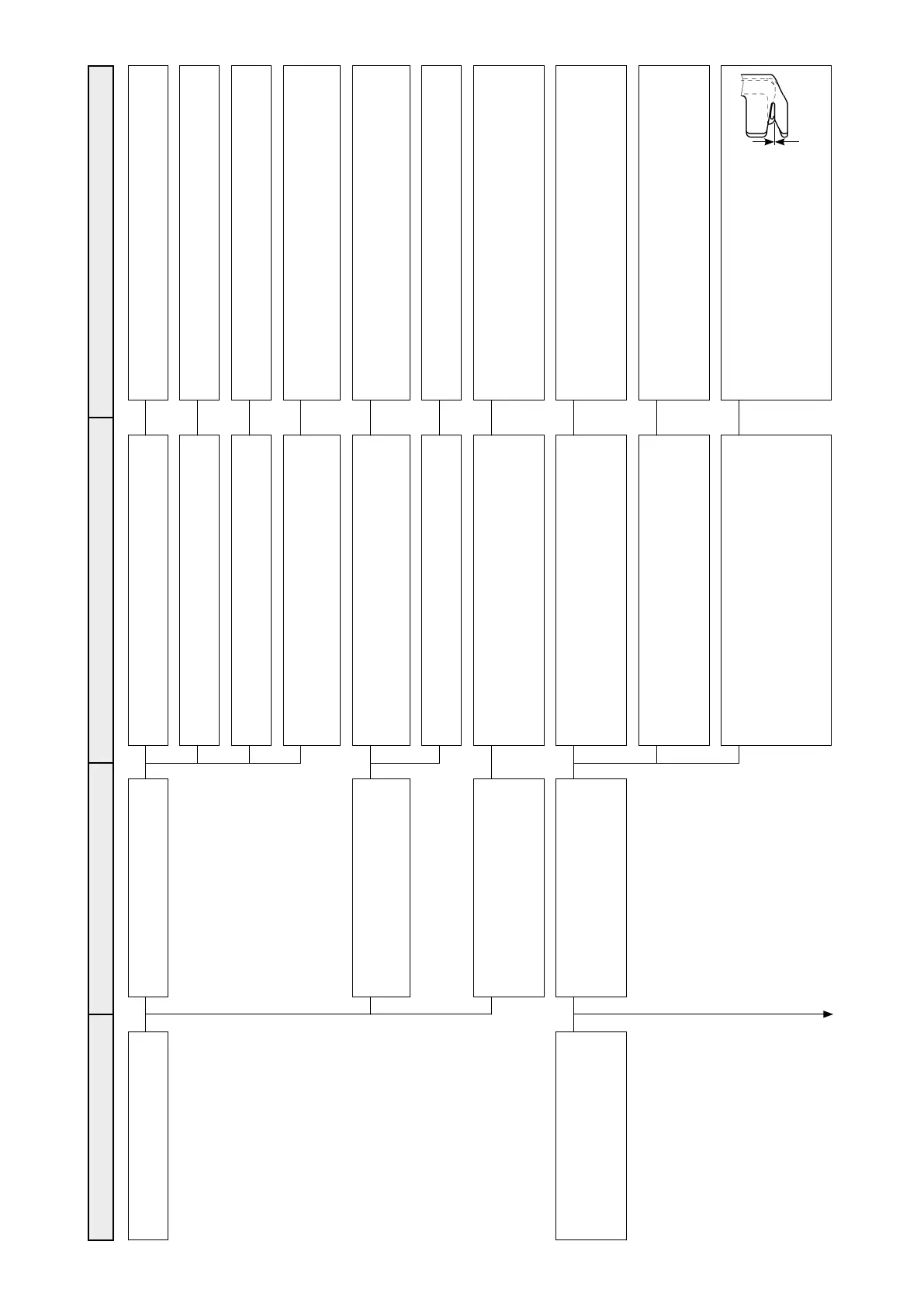

Trouble Case (1) Case (2) Check and Corrective measures

16. The looper thread cannot

be passed.

16-1) Thread path pipe 1-A) The pipe is clogged with dust. Remove dust with a threader supplied with the

machine.

1-B) Scratches inside the pipe Pull the thread from the looper by hand to check

whether it is caught by any part.

1-C) The pipe is lubricated due to malopera-

tion.

Pass a thick thread (cotton thread count of which

is #20 or lower) through the pipe to remove oil.

1-D) The piston lip of the pump is applied

with an excessive amount of grease. As

a result, the grease enters the pipe.

Take the aforementioned corrective measure.

16-2) The pump pressure is

too low. No air ows

inside the pump.

2-A) The pump piston does not move

smoothly.

Apply a small amount of grease to the periphery of

the piston lip. If the piston lip has worn out, replace

it with a new one.

2-B) The air tube has crushed. Pull out the tube from the pump. Twist it to correct

the bend.

16-3) The lever does not move

if it is operated. (It does

not move to the looper

side.)

3-A) An extra force is applied to the lever to

deform the sheet metal.

Correct the deformed part of the lever, or replace it

with a new one.

17. Faulty needle threader 17-1) The needle cannot be

threaded.

1-A) The hook has bent and lost its lateral

center. As a result, the needle threader

cannot enter the needle eyelet.

Correct the hook so that it is positioned equidis-

tantly from the right and left needle guide plates. If

this corrective measure cannot be taken, replace

the needle threader with a new one.

1-B) The hook radius has increased. As a re-

sult, the thread slips o the hook before

the needle threader enters the needle

eyelet.

Replace the needle threader with a new one.

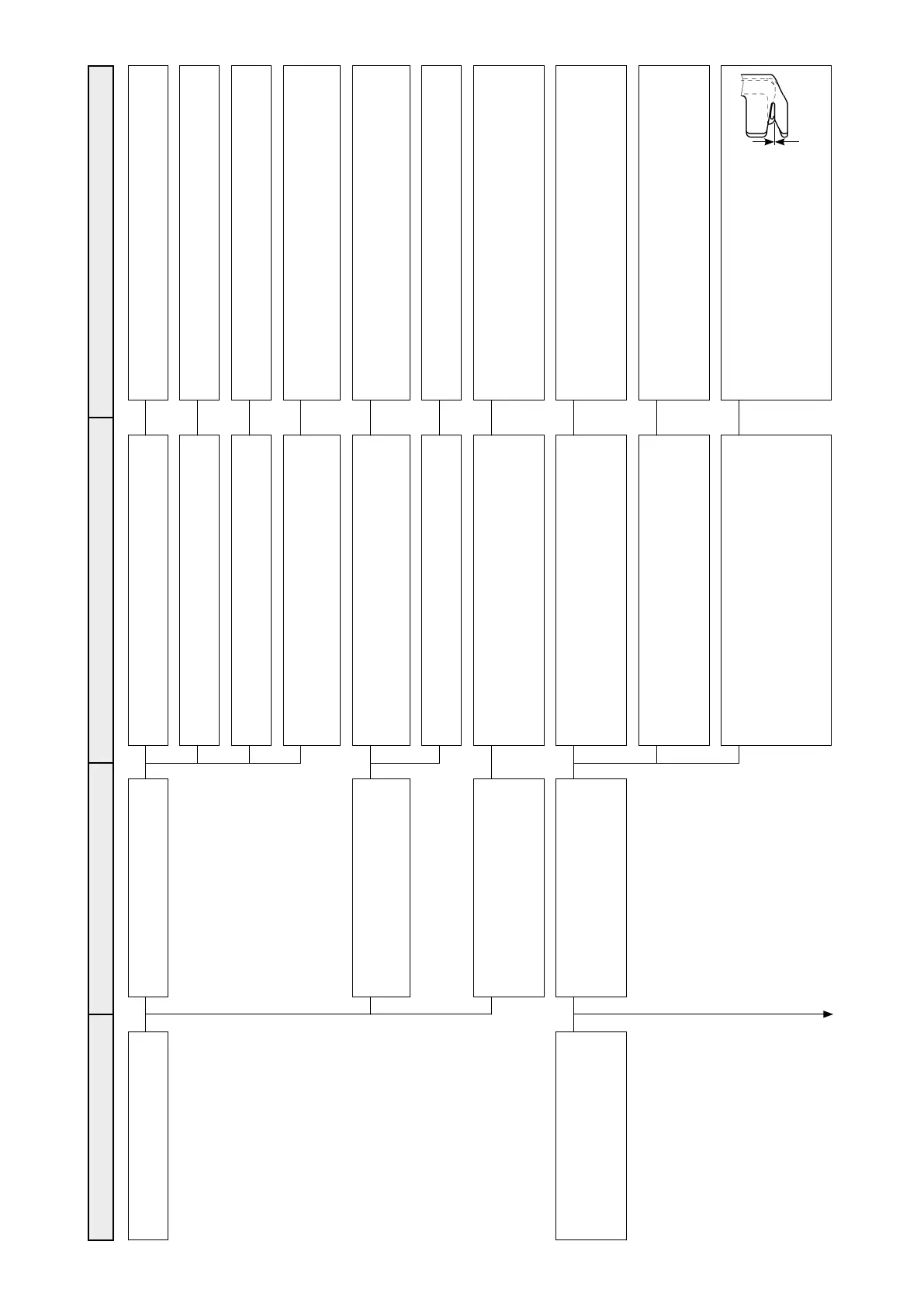

1-C) The hook has bent downward and pre-

vents the needle from being passed to

the end.

When the hook is correctly posi-

tioned, the lower side of the hook

is aligned with the lower side of the

needle guide plate. If the corrective

measure is hard to be taken, replace

the needle threader with a new one.

0 to 0.1

to the next page

Loading...

Loading...