– 26 –

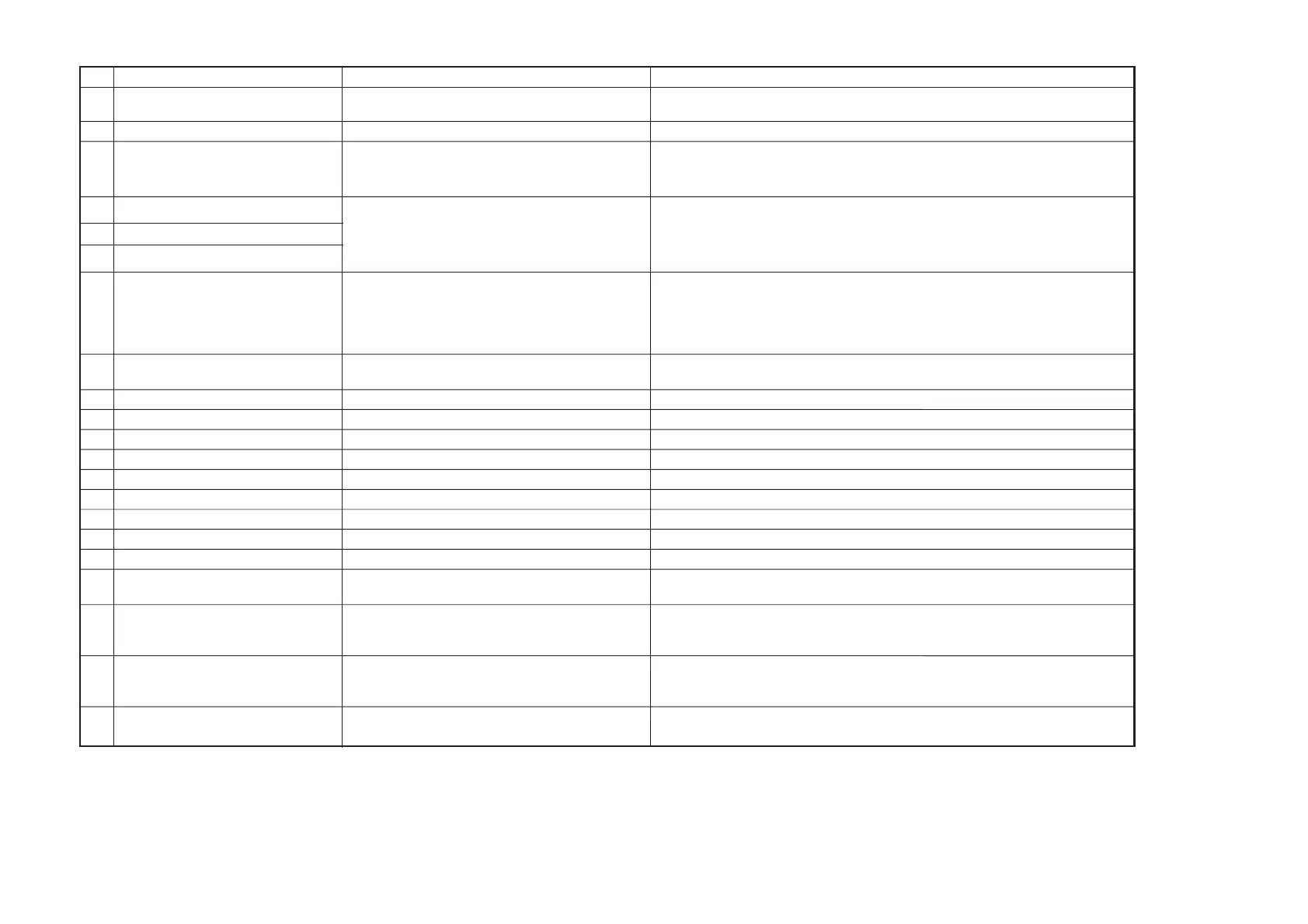

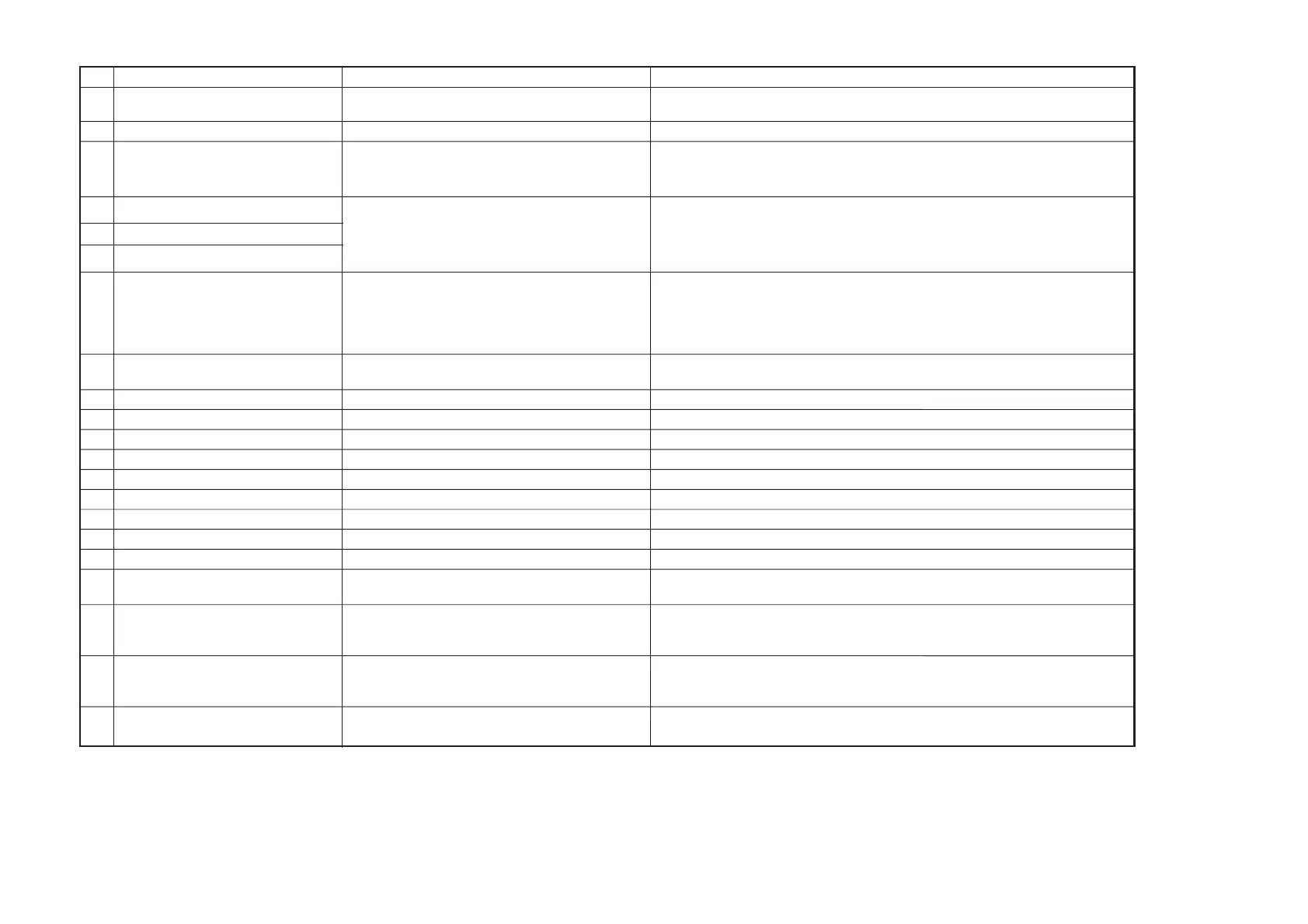

2) Error code list (Error display in panel)

There are the following error codes in this device. These error codes interlock (or limit function) and inform the

problem so that the problem is not enlarged when any problem is discovered. When you request our service, please

confirm the error codes.

— UP position detection error when turn- 1. When needle position is not UP position at the 1. Set to UP position by turning handwheel by hand.

ing ON the power time of turning ON the power. 2. Connect synchronizer connector.

— Media cover open 1. Lid of media slot is open. Close the lid.

E000 Execution of data initialization 1. EEPROM initialization is executed. —

(Not error) 2. Resistor pack is replaced.

3. When machine head is replaced.

E003 Disconnection of synchronizer connector 1. When position detection signal is not inputted from 1. Check the synchronizer connector (CN30) for loose connection and disconnection.

the sewing machine head synchronizer.2.Check whether the synchronizer cord has broken since the cord is caught in the

2. When the synchronizer has broken. machine head or the like.

E005 Synchronizer upper position sensor failure

E007 Overload of motor 1. When the machine head is locked. 1. Check whether the thread has been entangled in the motor pulley.

2. When sewing extra-heavy material beyond the 2. Check the motor output connector (4P) for loose connection and disconnection.

guarantee of the machine head. 3. Check whether there is any draw when turning motor by hand.

3. When the motor does not run.

4. Motor or driver is broken.

E008 Machine head connector failure When the machine head connector is not properly read. Check the machine head connector (CN31) for loose connection and disconnection.

(Resistance pack)

E011 Compact flash (TM) not inserted Compact flash (TM) is not inserted. Return after reset operation.

E012 Read error Data read from compact flash (TM) is not possible. Return after reset operation.

E013 Write error Data write to compact flash (TM) is not possible. Return after reset operation.

E014 Write protect Compact flash (TM) is in write prohibition state. Return after reset operation.

E015 Format error Formatting cannot be performed. Return after reset operation.

E016 External media capacity over Media capacity of compact flash (TM) is short. Return after reset operation.

E019 File size over File is too big. Return after reset operation.

E021 Access error Abnormality of access of file Return after reset operation.

E032 File compatibility error There is not file compatibility.Turn OFF the power.

E046 Both-needle lock When the power supply is turned on, both needles are 1. Check whether the right or left needle position origin sensor is broken.

(When LH-4168, 4188 is selected) locked. (Needles are located in rising positions.) 2. Check whether the sensor connector wire is broken or disconnected.

E053 Execution of panel backup data When model code of panel does not agree with that Turn OFF the power.

initialization. (Not error) of control box.

When executing initialization operation when the panel.

E220 Grease fill-up time information When grease fill-up time to the specified place has After turning OFF the power, perform grease fill-up, and set Function No. 118 to “1”.

come. When grease fill-up cannot be performed during sewing, release of error can be

performed with the reset key of the panel.

E221 Grease-up error LH-41** Machine head greasing alarm Replenish the specified grease and execute resetting operation.

(Grease replenishment alarm after the lapse of specified time)

No. Description of error detected Cause Item to be checked or corrective measure

E004 Synchronizer upper position sensor failure

Loading...

Loading...