– 83 –

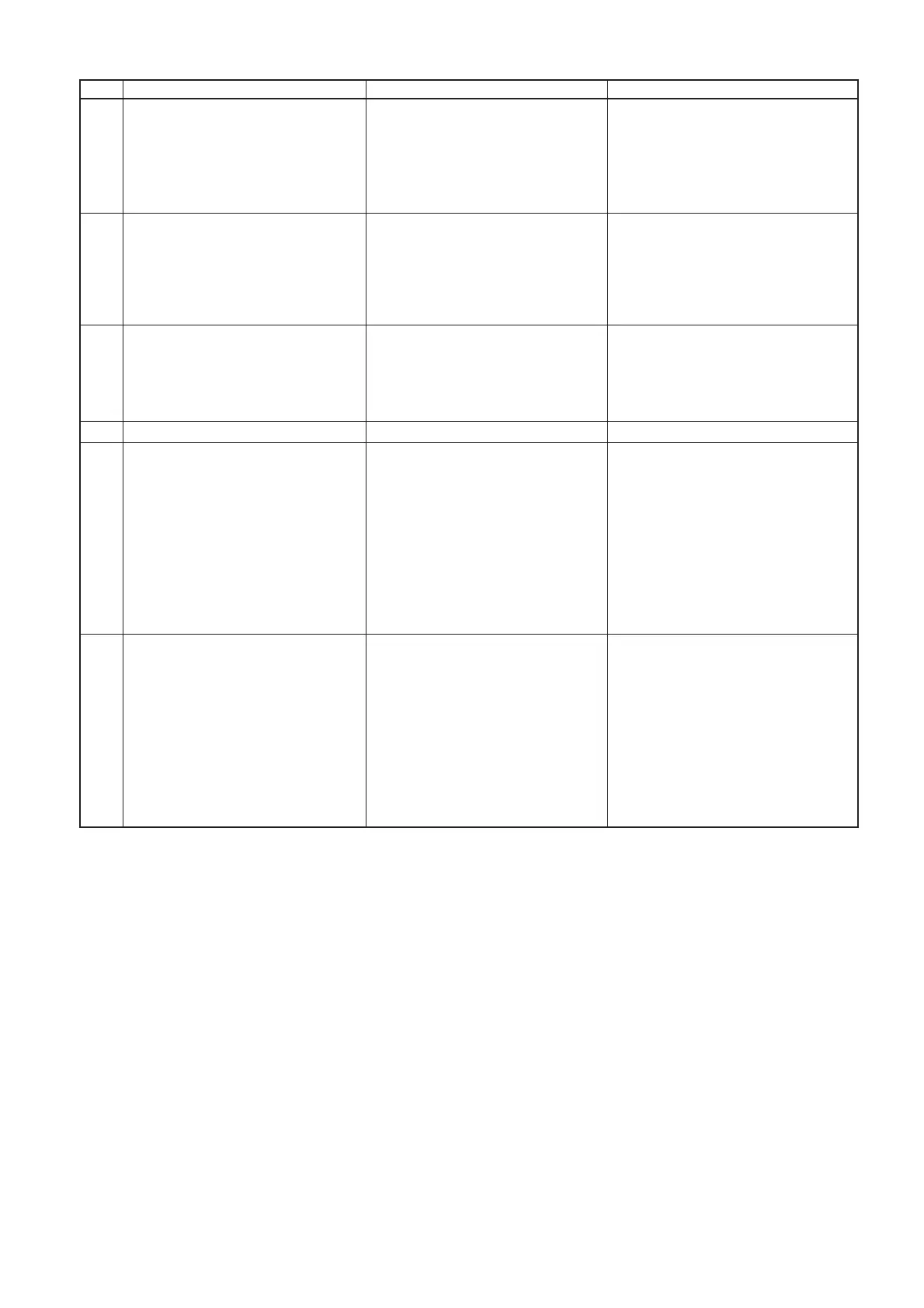

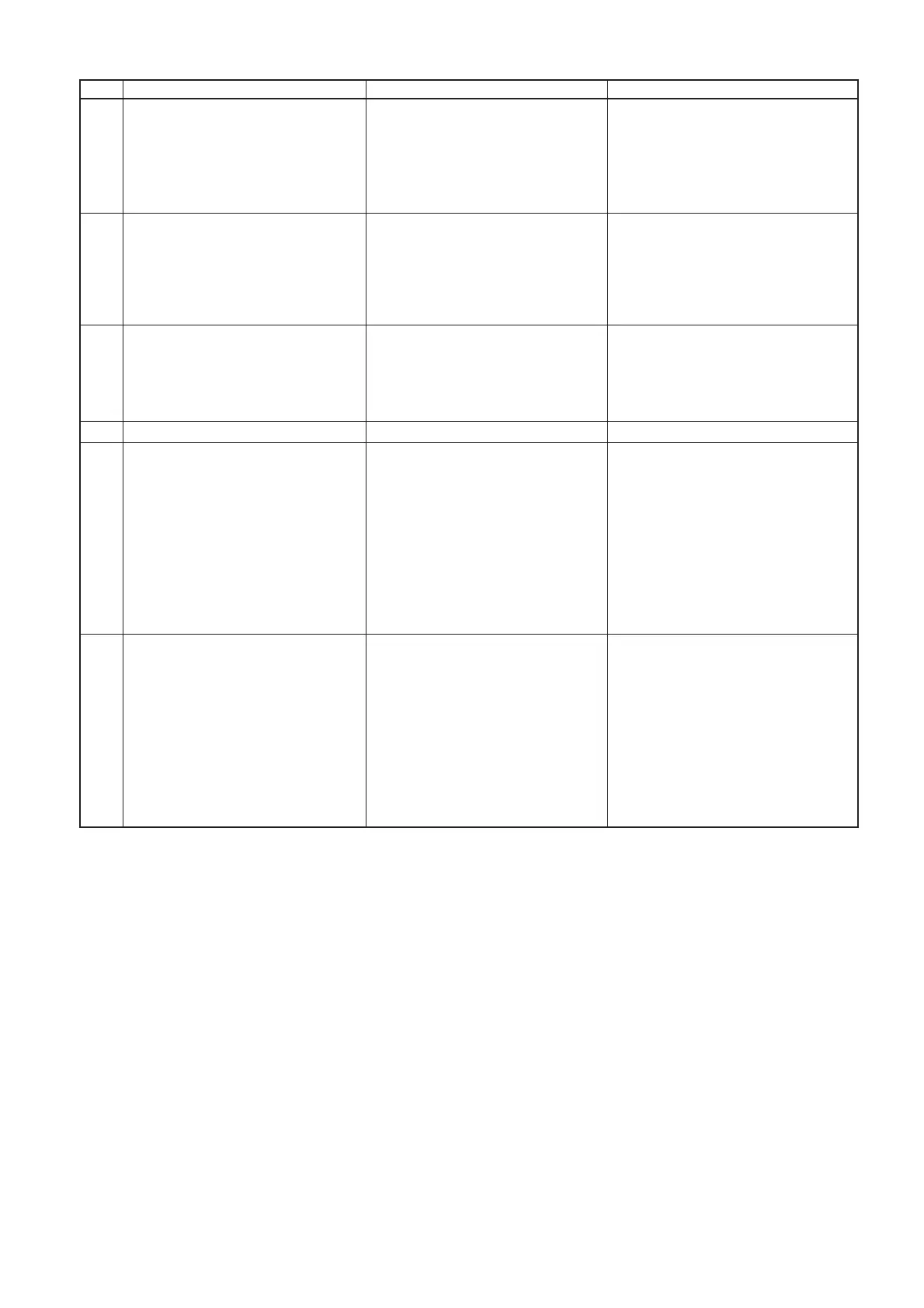

No. Description of error detected Cause of occurrence expected Items to be checked

E811 Overvoltage • When voltage higher than guaranteed • Check whether the applied power voltage

one is inputted. is higher than the rated voltage + (plus) 10%

or more.

• When the 100V input power is applied • Check whether 100V/200V changeover

int the state of 200V setting. connector is improperly set.

• JUS : 220V is applied to the box of 120V. In the aforementioned cases, POWER

• CE : 400V is applied to the box of 230V. p.c.b is broken.

E813 Low voltage • When voltage lower than guaranteed • Check whether the voltage is lower than

one is inputted. the rated voltage - (minus) 10% or less.

• When the 100V input power is applied • Check whether 100V/200V changeover

int the state of 200V setting. connector is improperly set.

• JUS : 120V is applied to the box of 220V.

•Inner circuit is broken by the applied • Check whether fuse or regenerative

overvoltage resistance is broken.

E906 Communication trouble between • Operation panel cord is disconnected. • Check whether operation panel connectors

operation panels • Operation panel is broken. (CN34 and CN35) are loosened or

disconnected.

• Check whether operation panel cord is

disconnected since the cord is caught

with machine head.

E924 Motor driver failure • Motor driver has broken.

E944 Left needle control impossible • Left needle has shifted from the origin • Check whether the left needle origin

(When LH-4168, or 4188 is selected) during holding it. sensor is broken.

• Left needle has shifted from the origin • Check whether needle bar has shifted

during releasing left needle. from the holding position by the exterior

force.

• Check whether the needle control con-

nectors (CN55 and CN56) have come

loose or are dislodged.

• Check whether the present program is

arranged for the simultaneous driving of

multiple solenoids with the step pattern

of IP-110.

E945 Right needle control impossible • Right needle has shifted from the origin • Check whether the right needle origin

(When LH-4168, or 4188 is selected) during holding it. sensor is broken.

• Right needle has shifted from the origin • Check whether needle bar has shifted

during releasing left needle. from the holding position by the exterior

force.

• Check whether the needle control con-

nectors (CN55 and CN56) have come

loose or are dislodged.

• Check whether the present program is

arranged for the simultaneous driving of

multiple solenoids with the step pattern

of IP-110.

Loading...

Loading...