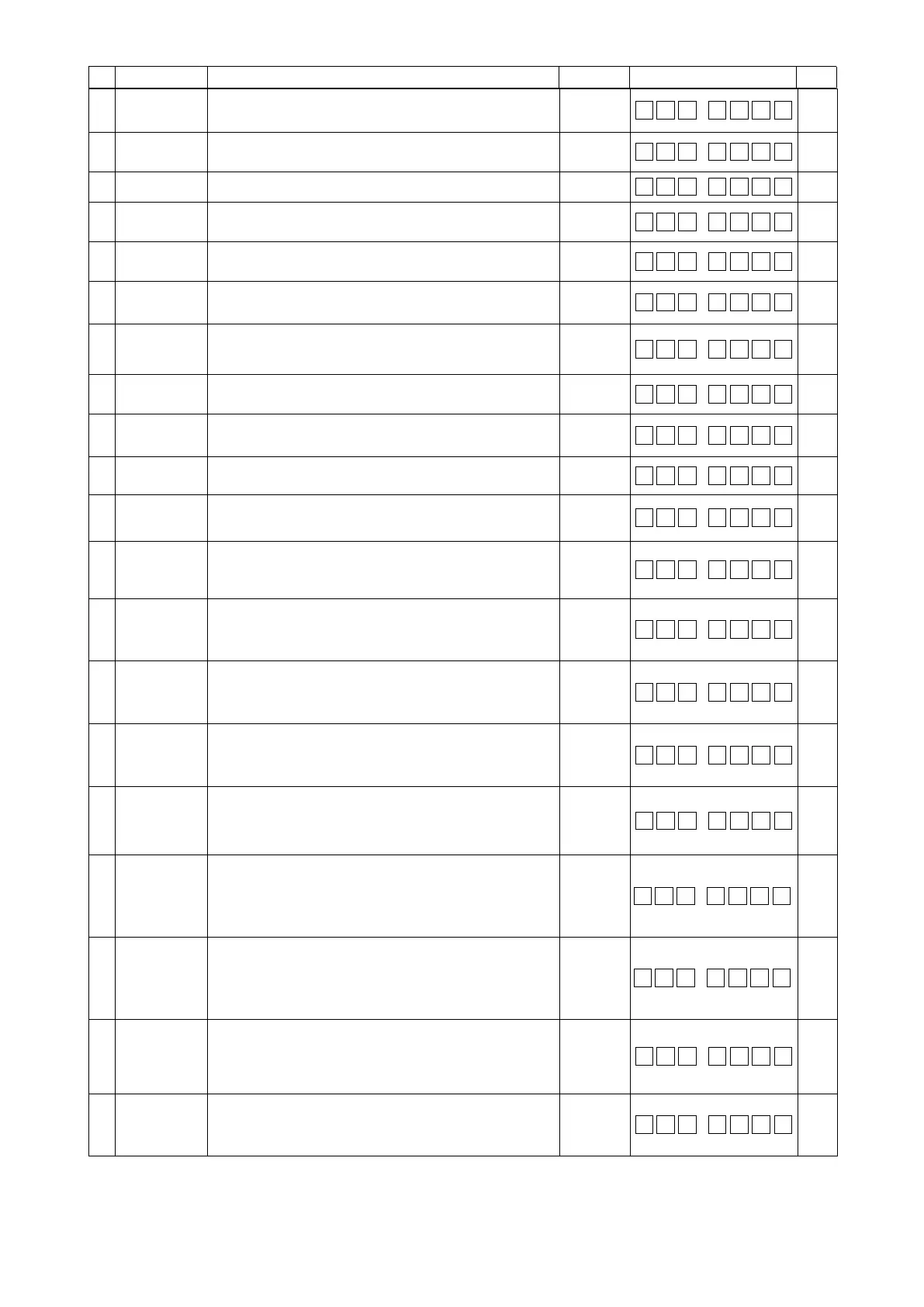

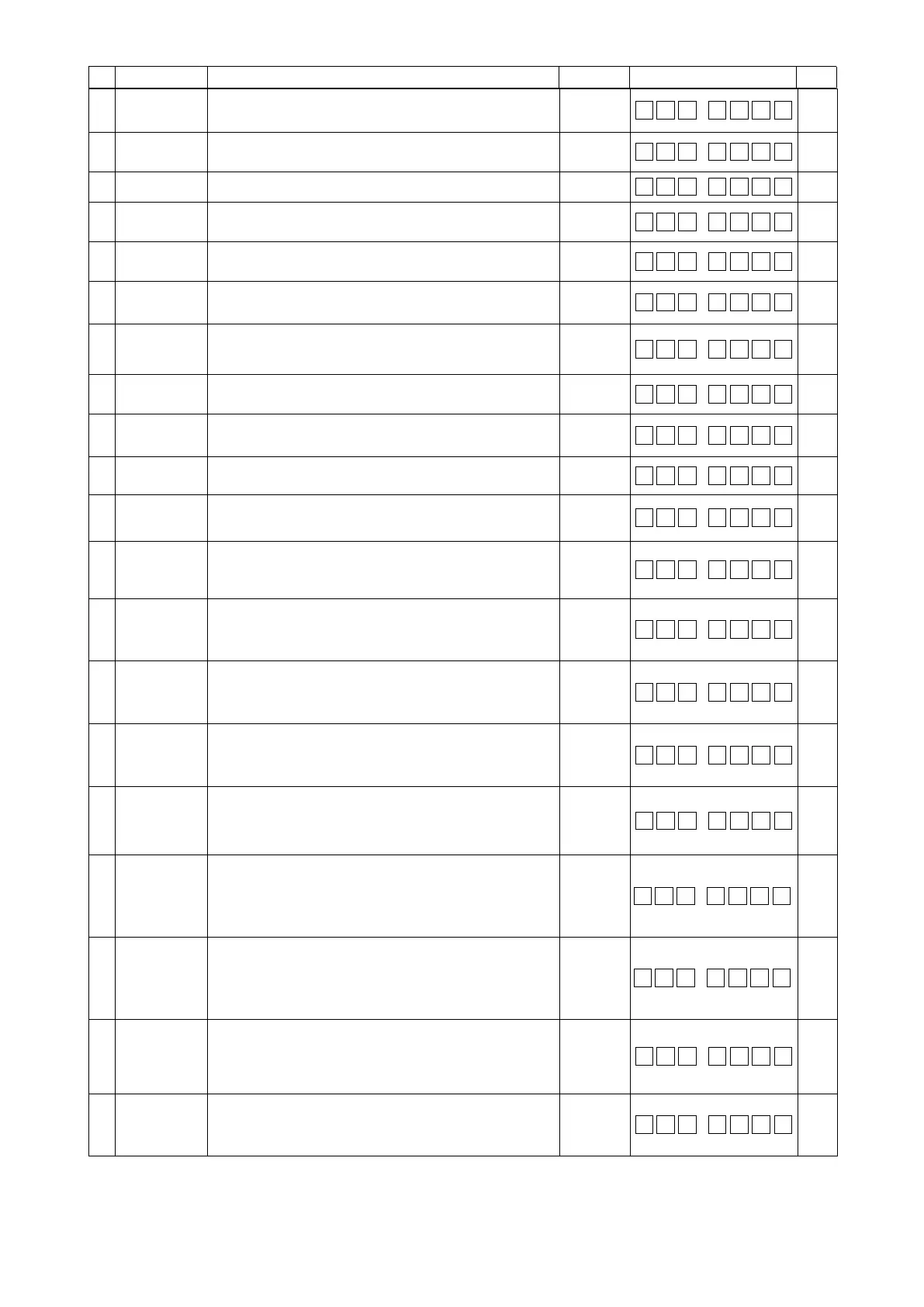

– 26 –

38 One-shot speed One-shot speed (The max. value depends on the number of ro-

tation of the sewing machine head.)

200 to MAX

(r.p.m.)

3 8 2 5 0 0

35

*

39 Pedal stroke

at the start of

rotation

Position where the sewing machine starts rotating from pedal

neutral position (Pedal stroke)

10 to 50

(0.1 mm)

3 9 3 0

*

40 Low speed

section of pedal

Position where the sewing machine starts accelerating from

pedal neutral position (Pedal stroke)

10 to 100

(0.1 mm)

4 0 6 0

*

41 Starting position

of lifting presser

foot by pedal

Position where the cloth presser starts lifting from pedal neutral

position (Pedal stroke)

– 60 to –10

(0.1mm)

4 1 – 2 1

*

42 Starting position

of lowering

presser foot

Starting position of lowering presser foot

Stroke from the neutral position

8 to 50

(0.1 mm)

4 2 1 0

*

43

Pedal stroke 2 for

starting thread

trimming

Position 2 where the thread trimming starts from pedal neutral

position(When the function of lifting presser foot by pedal is pro-

vided.) (Pedal stroke)

– 60 to –10

(0.1 mm)

4 3 – 5 1

*

44

Pedal stroke

for reaching the

maximum number

of rotation

Position where the sewing machine reaches its highest sewing

speed from pedal neutral position (Pedal stroke)

10 to 150

(0.1 mm)

4 4 1 5 0

*

45

Compensation of

neutral point of

the pedal

Compensation value of the pedal sensor

–15 to 15

4 5 0

*

46

Auto-lifter

selecting function

Auto-lifter selection

0 : Solenoid drive system

1 : Pneumatic drive system

0/1

4 6 0

*

47

Auto-lifter

selecting function

Limitation time of waiting for lifting solenoid type auto-lifter de-

vice

10 to 600

(second)

4 7 6 0

35

*

48

Pedal stroke 1 for

starting thread

trimming

Position where thread trimming starts from pedal neutral position

(Standard pedal) (Pedal stroke)

– 60

to – 10

(0.1 mm)

4 8 – 3 5

49

Lowering time of

presser foot

Lowering time of presser foot after the pedal has been de-

pressed.

(Start of rotation of the sewing machine is delayed during this

time.)

0

to 250

(10 ms)

4 9 1 4 0

37

51 Compensation of

solenoid-on timing

of reverse feed

stitching at the

start of sewing

Compensation of starting the solenoid for reverse feed stitching

when reverse feed stitching at the start of sewing is performed.

– 36 to 36

(10°)

5 1 – 1 8

35

52 Compensation of

solenoid-off timing

of reverse feed

stitching at the

start of sewing

Compensation of releasing the solenoid for reverse feed stitch-

ing when reverse feed stitching at the start of sewing is per-

formed.

– 36 to 36

(10°)

5 2 – 5

35

53 Compensation of

solenoid-off timing

of reverse feed

stitching at the

end of sewing

Compensation of releasing the solenoid for reverse feed stitch-

ing when reverse feed stitching at the end of sewing is per-

formed.

– 36 to 36

(10°)

5 3 – 5

35

55

Foot lift after

thread trimming

Function of lifting presser foot at the time of (after) thread trimming

0 : Not provided with the function of lifting presser foot after

thread trimming

1 : Provided with the function of lifting presser foot

automatically

after thread trimming

0/1

5 5 1

36

56

Reverse

revolution to lift

the needle after

thread trimming

Function of reverse revolution to lift the needle at the time of (af-

ter) thread trimming

0 : Not provided with the function of reverse revolution to lift

the needle after thread trimming

1 : Provided with the function of reverse revolution to lift the

needle after thread trimming

0/1

5 6 0

36

57

Bobbin thread

remaining amount

detection function

Function of detecting bobbin thread remaining amount at the

time of (after thread trimming

0 : Not provided with the function of detecting bobbin thread

remaining amount

1 : Provided with the function of detecting bobbin thread re-

maining amount

0/1

5 7 0

36

58

Function

of holding

predetermined

upper/lower

position of the

needle bar

Function of holding predetermined upper/lower position of the needle bar

0 : Not provided with the function of holding predetermined up-

per/lower position of the needle bar

1 : Provided with the function of holding predetermined upper/

lower position of the needle bar

0/1

5 8 0

36

59

Function of Auto/

Manual change-

over of reverse

feed stitching at

the start of sewing

This function can specify the sewing speed of reverse feed

stitching at the start of sewing.

0 : The speed will depend on the manual operation by pedal, etc.

1 :

The speed will depend on the specied reverse feed stitching speed (No. 8).

0/1

5 9 1

36

No

Item Description

Setting range

Indication of function setting

Ref. page

*

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery of DDL-9000A.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

Loading...

Loading...