– 46 –

I

n addition, there are the following error codes in this device. These error codes interlock (or limit function) and inform

the problem so that the problem is not enlarged when any problem is discovered. When you request our service, please

conrm the error codes.

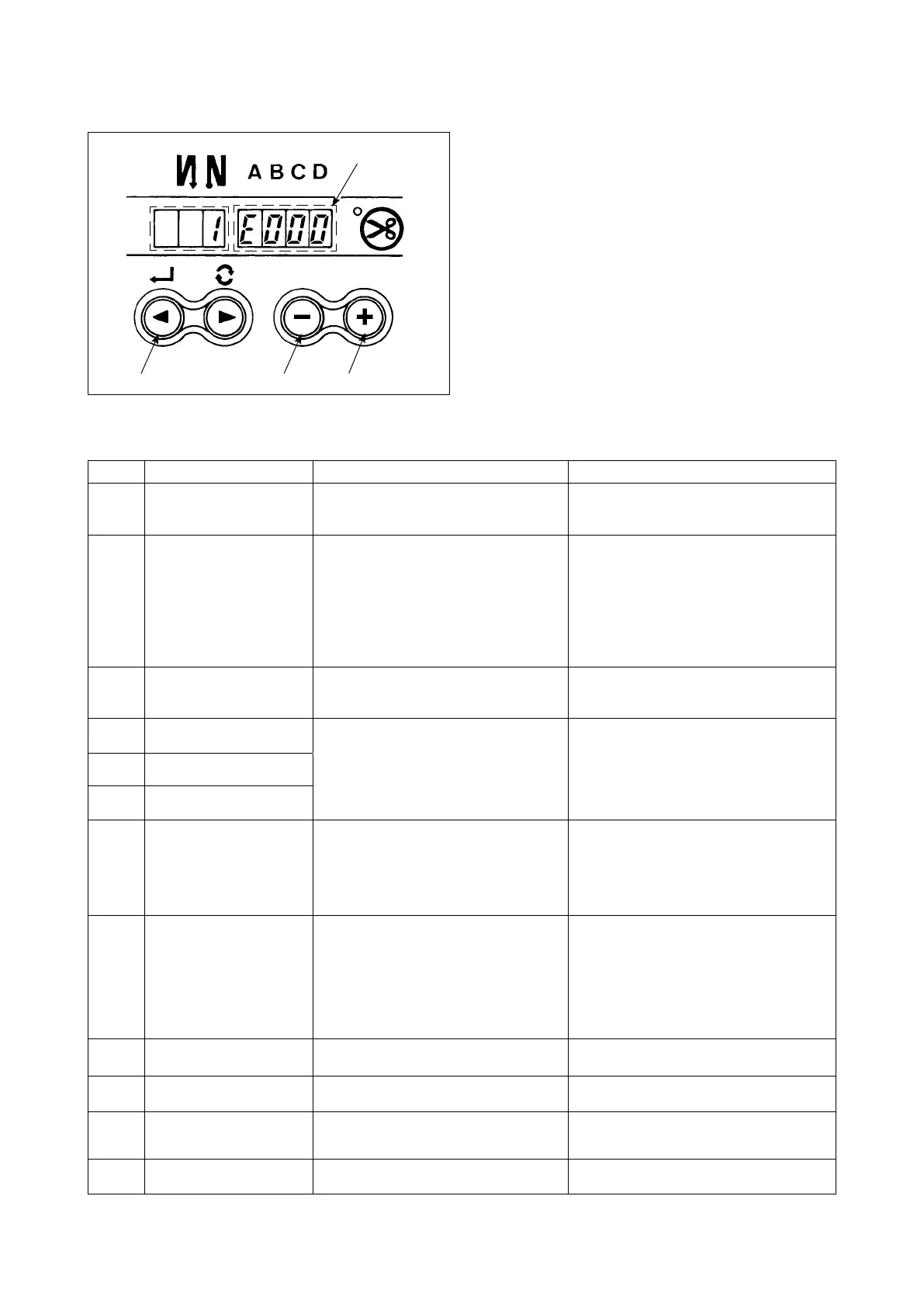

Checking procedure of the error code

1) Pressing switch

1

in the control box, turn ON the

power switch.

2) LED becomes display

2

with the sound of “peep” and

the latest error code is displayed.

3) Conrmation of the contents of previous error can

be performed by operating switches

3

or

4

. (When

the conrmation of the contents of previous error

advanced to the last, the warning sound peeps in

single tone two times.)

(Caution) When operating switch

3

, one before the

existing error code is displayed.

When operating switch

4

, one after the ex-

isting error code is displayed.

Error code list

No.

Description of error detected

Cause of occurrence expected Items to be checked

E000 Execution of data

initialization (This is not

the error.)

• When the machine head is changed.

• When the initialization operation is

executed

E302 Fall detection switch failure

(When the safety switch

works)

• When fall detection switch is input in the

state that the power is turned ON.

• Check whether the machine head is tilted

without turning OFF the power switch (sewing

machine operation is prohibited for safety

sake).

• Check whether the fall detection switch cord

is caught in the sewing machine or the like.

• Check whether the fall detection switch lever

is caught in something.

E221 Grease-up error • Greasing warning of LH-41**

(Greasing warning after passing the

specied time)

• Perform greasing and execute the reset

operation.

E003 Disconnection of

synchronizer connector

• When position detection signal is not

input from the sewing machine head

synchronizer.

• When the synchronizer has broken.

• Check the synchronizer connector (CN30)

for loose connection and disconnection.

• Check whether the synchronizer cord has

broken since the cord is caught in the

machine head.

E004 Synchronizer lower

position sensor failure

E005 Synchronizer upper

position sensor failure

E906 Operation panel

transmission failure

• Disconnection of operation panel cord

• Operation panel has broken.

• Che ck the operation pan el con necto r

(CN34, CN35) for loose connection and

disconnection.

• Check whether the operation panel cord

has broken since the cord is caught in the

machine head.

E007 Overload of motor • When the machine head is locked.

•

When sewi ng extr a-h eav y m ate ria l

beyond the guarantee of the machine

head.

• When the motor does not run.

• Motor or driver is broken.

• Ch e ck wh e the r t he thr e ad ha s b e en

entangled in the motor pulley.

• Check the motor output connector (4P) for

loose connection and disconnection.

• Check whether there is any holdup when

turning the motor by hand.

E008 Machine head connector

failure (Resistance pack)

• When the machine head connector is not

properly read.

• Check the machine head connector (CN31)

for loose connection and disconnection.

E808 Solenoid short circuit • S ol e no i d po w er do e s no t b ec o me

normal voltage.

• Check whether the machine head cord is

caught in the pulley cover or the like.

E809 Holding motion failure • Solenoid is not changed over to holding

motion.

• Check whether the solenoid is abnormally

heated. (CTL circuit board asm. Circuit is

broken.

E810 Solenoid current

abnormality

• Solenoid rare short-circuit. • Solenoid resistance

2

1

3

4

Loading...

Loading...