0999.GB

F 4

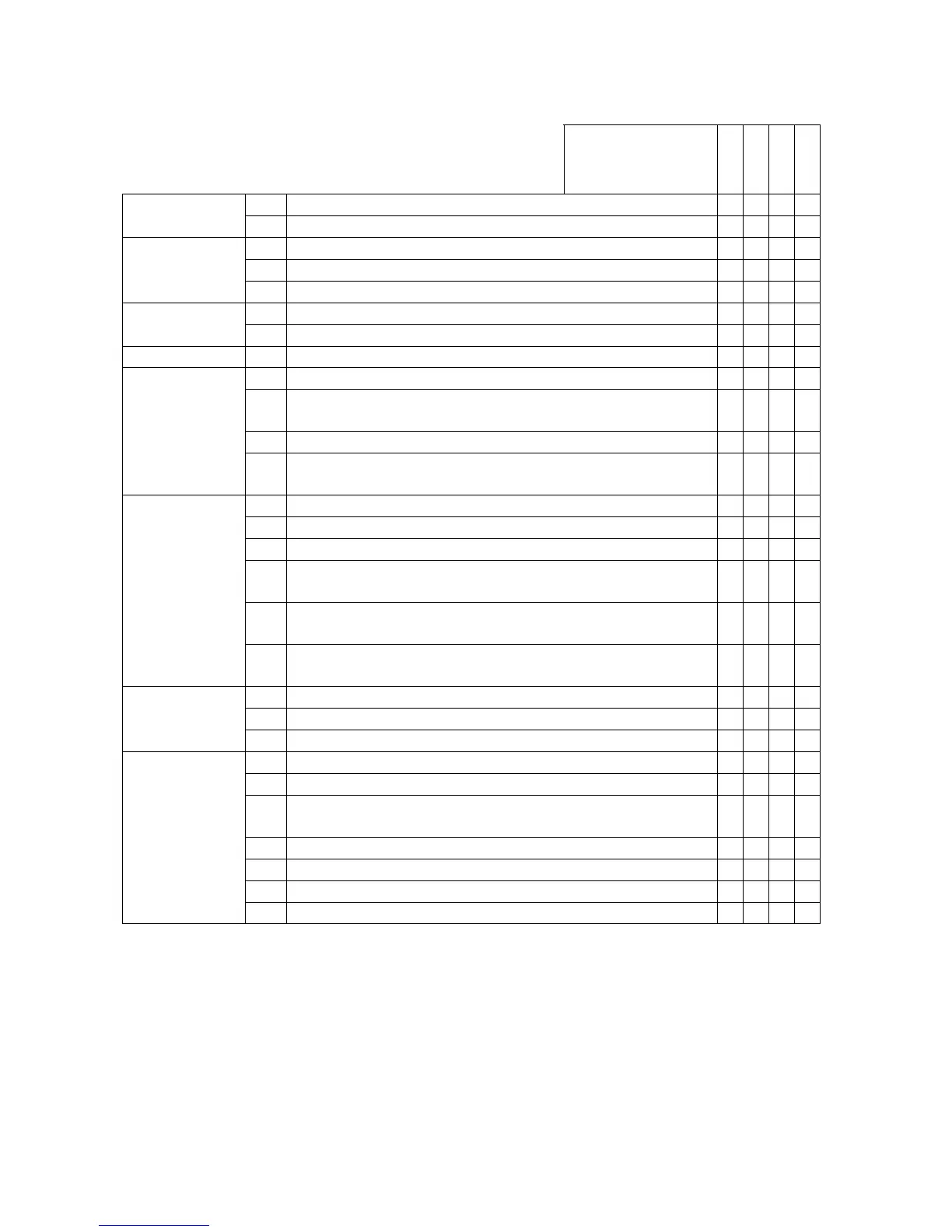

4 Maintenance checklist

a) First check of the wheel nuts after approx. 100 operating hours for tight fit. Re-tighten if

necessary. For starting torque, see maintenance plan.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) 1. exchange after 500 hours of operation / if required, change coarse sieve.

d) Check the wheel arm fastening screws for the first time after approx. 100 operating hours

and re-tighten, if necessary. For starting torque, see maintenance plan.

A

The maintenance intervals refer to normal service conditions. If you are working un-

der difficult conditions, reduce the intervals, if required.

Maintenance intervals

Standard =

t

WMMM

Cold-stora-

ge depot

=

k

13612

Chassis/

Design:

1.1 Check all load bearing elements for damage

t

1.2 Check all bolted connections d)

t

Drive unit: 2.1 Check the transmission for noises and leakage

t

2.2 Check the transmission oil level

t

2.3 Change the gear oil

kt

Wheels: 3.1 Check for wear and damage

t

3.2 Check seating and attachment a)

kt

Steering: 4.1 Check the steering clearance

t

Brake

system:

5.1 Check for correct function and adjustment

kt

5.2 Check the return spring for repositioning function and

damage

t

5.3 Check the brake linings for wear

t

5.4 Check the brake linkage; adjust and grease,

if necessary

kt

Hoist frame: 6.1 Visual check of rollers, slide pieces and stops

kt

6.2 Check fork tines and fork carrier for wear and damage

kt

6.3 Check secure attachment of hoist frame

t

6.4 Check lift chains and chain guide for wear, adjust and

grease them.

t

6.5 Check the lateral clearance of the mast profiles and

whether they are parallel to each other

t

6.6 Check safety devices for proper attachment

and damages

kt

Lifting device: 7.1 Check function, wear and tear and adjustment

t

7.2 Visual check of rollers, slide pieces and stops

kt

7.3 Check fork tines and fork carrier for wear and damage

kt

Hydr. system: 8.1 Check function

kt

8.2 Check all connections for leakage and damage b)

kt

8.3 Check hydraulic cylinders for leakage, damage and

secure attachment

kt

8.4 Check the oil level

kt

8.5 Change hydraulic oil c)

kt

8.6 Change filter

t

8.7 Check the pressure relief valves for correct functioning

kt

0999.GB

F 4

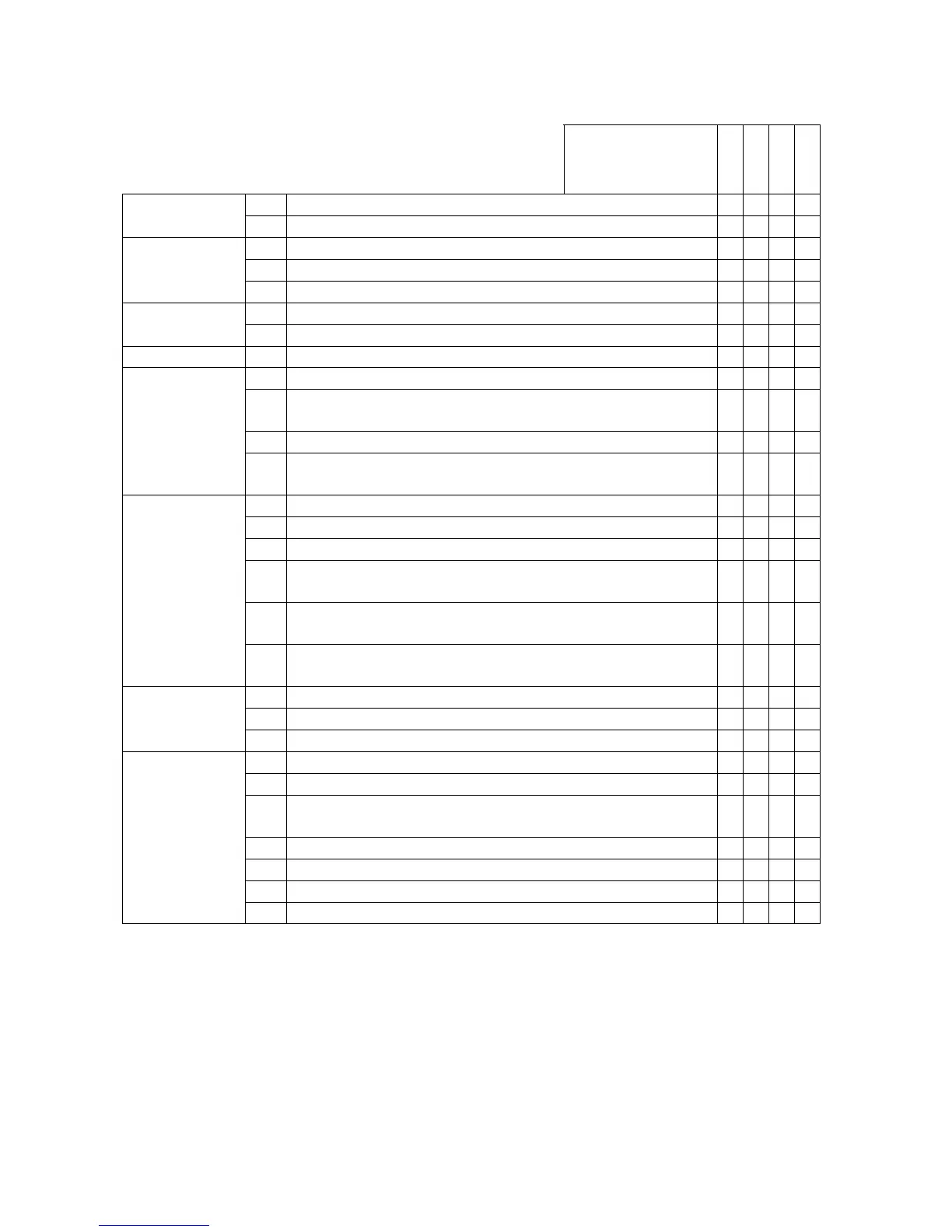

4 Maintenance checklist

a) First check of the wheel nuts after approx. 100 operating hours for tight fit. Re-tighten if

necessary. For starting torque, see maintenance plan.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) 1. exchange after 500 hours of operation / if required, change coarse sieve.

d) Check the wheel arm fastening screws for the first time after approx. 100 operating hours

and re-tighten, if necessary. For starting torque, see maintenance plan.

A

The maintenance intervals refer to normal service conditions. If you are working un-

der difficult conditions, reduce the intervals, if required.

Maintenance intervals

Standard =

t

WMMM

Cold-stora-

ge depot

=

k

13612

Chassis/

Design:

1.1 Check all load bearing elements for damage

t

1.2 Check all bolted connections d)

t

Drive unit: 2.1 Check the transmission for noises and leakage

t

2.2 Check the transmission oil level

t

2.3 Change the gear oil

kt

Wheels: 3.1 Check for wear and damage

t

3.2 Check seating and attachment a)

kt

Steering: 4.1 Check the steering clearance

t

Brake

system:

5.1 Check for correct function and adjustment

kt

5.2 Check the return spring for repositioning function and

damage

t

5.3 Check the brake linings for wear

t

5.4 Check the brake linkage; adjust and grease,

if necessary

kt

Hoist frame: 6.1 Visual check of rollers, slide pieces and stops

kt

6.2 Check fork tines and fork carrier for wear and damage

kt

6.3 Check secure attachment of hoist frame

t

6.4 Check lift chains and chain guide for wear, adjust and

grease them.

t

6.5 Check the lateral clearance of the mast profiles and

whether they are parallel to each other

t

6.6 Check safety devices for proper attachment

and damages

kt

Lifting device: 7.1 Check function, wear and tear and adjustment

t

7.2 Visual check of rollers, slide pieces and stops

kt

7.3 Check fork tines and fork carrier for wear and damage

kt

Hydr. system: 8.1 Check function

kt

8.2 Check all connections for leakage and damage b)

kt

8.3 Check hydraulic cylinders for leakage, damage and

secure attachment

kt

8.4 Check the oil level

kt

8.5 Change hydraulic oil c)

kt

8.6 Change filter

t

8.7 Check the pressure relief valves for correct functioning

kt

Loading...

Loading...