F 9

0999.GB

6.4 Check hydraulic oil level

– Prepare the truck for servicing and maintenance operations (see section 6.1).

– Open the front hood (see section 6.3).

– Check the hydraulic oil level of the hydraulic tank (see section 5).

A

There are markings on the hydraulic tank (see section 5). The oil level must be chek-

ked with the lifting device being lowered.

– If required, top up with hydraulic oil with the required characteristics

(see section 5.1; see table)

A

Mounting is performed in reverse order.

6.5 Check the transmission oil level

– Prepare the truck for servicing and maintenance operations (see section 6.1).

– Open the front hood (see section 6.3).

– Loosen 2 x screws (5) using the key (2).

– Remove carefully the wheel cover (4).

– Check gear-oil level - oil level must reach the filler neck

(see section 5).

– If required, top up with gear oil with the required characteristics (see section 5.1).

A

Mounting is performed in reverse order.

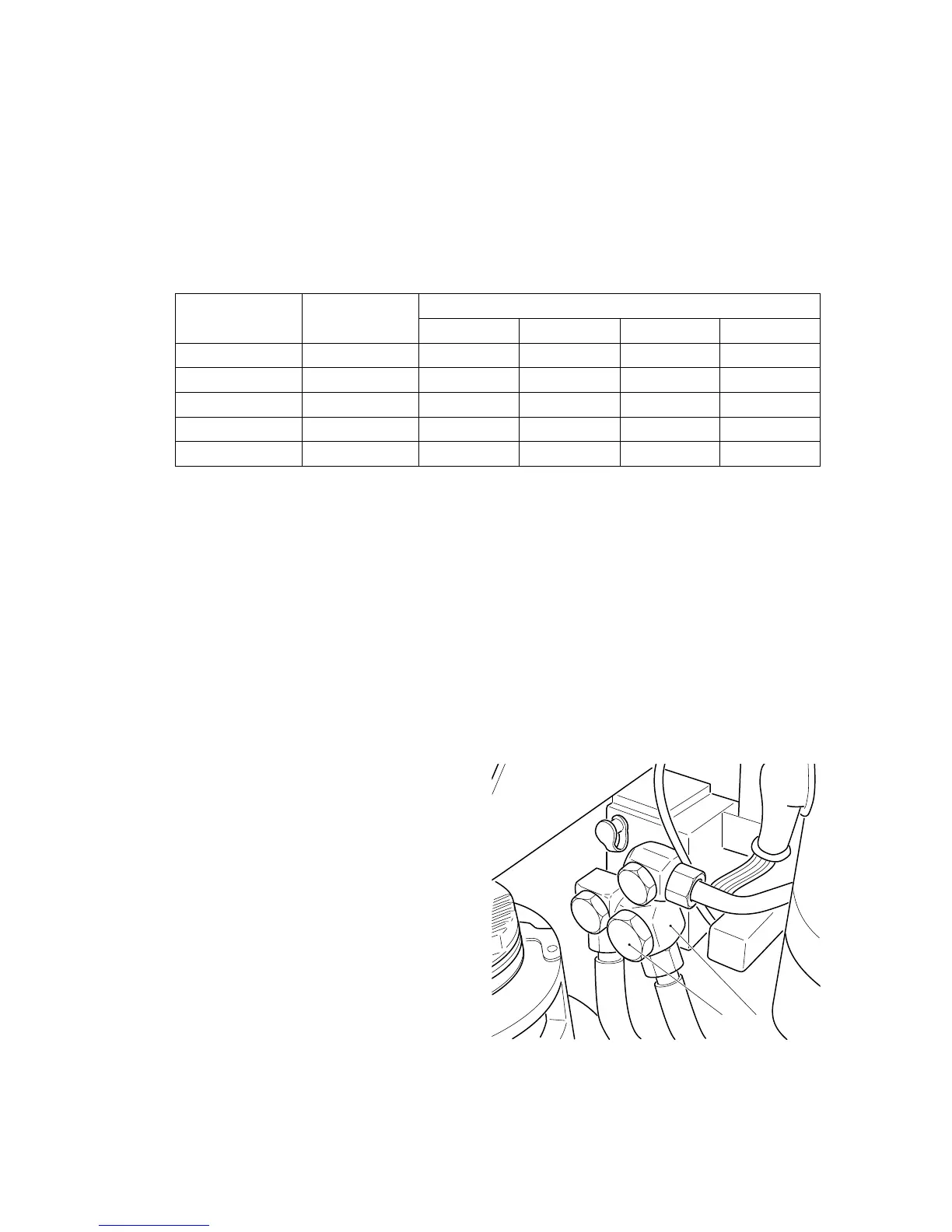

6.6 Exchanging the coarse sieve

– Preparation of the truck for servicing

and maintenance operations

(refer section 6.1).

– Open the front hood (see chapter F,

section 6.3).

– Loosen the screwed connection (6).

– Pull off the connection (7) and remove

the coarse sieve.

– Insert a new coarse sieve.

m

Mounting is performed in reverse order.

m

Tighten screwed connection (6) with

max. 60

+10

Nm.

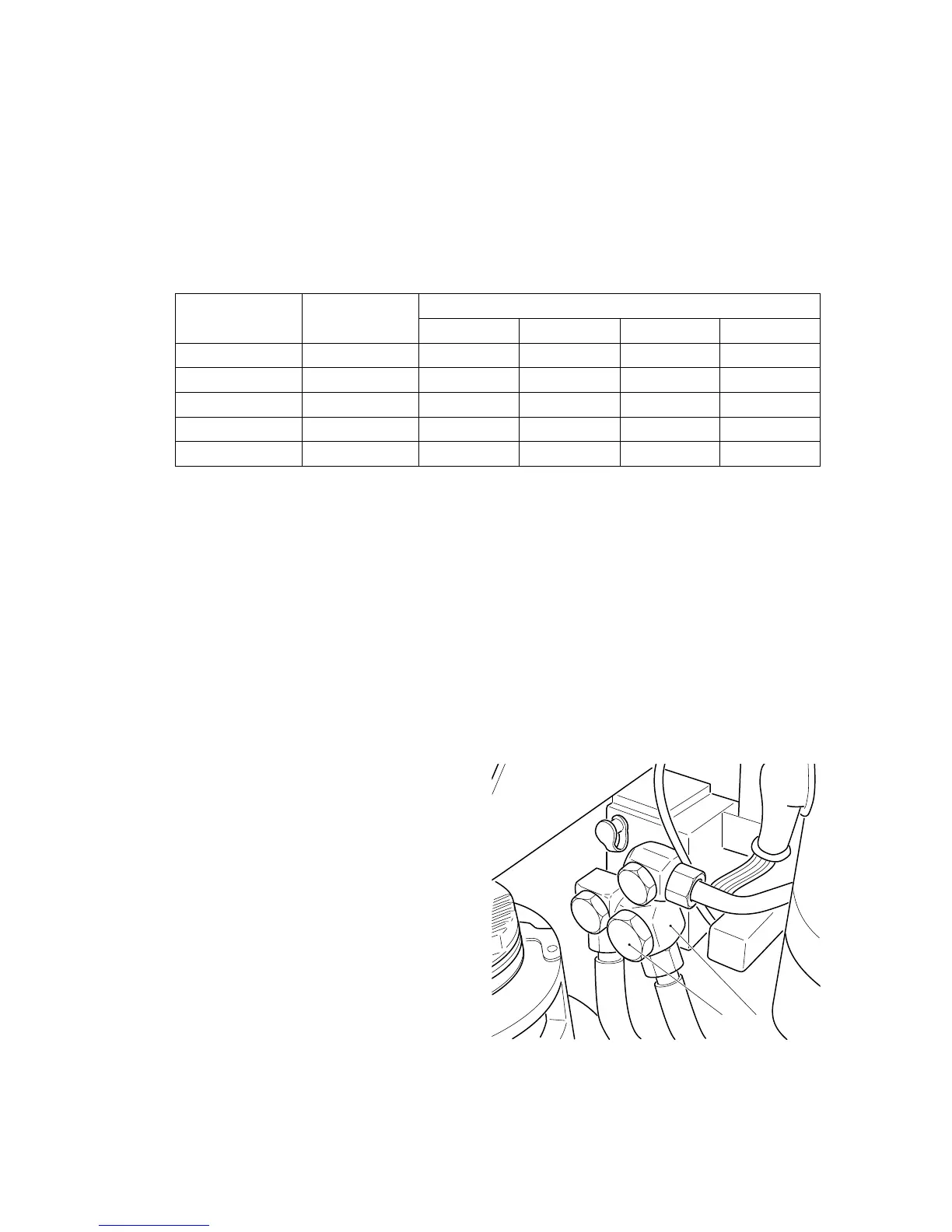

Marking Litre Lifting heights (h

3

)

EZTZZDZ

Upper edge approx. 10.5 - - - up to 5350

4approx. 10----

3 approx. 8.3 - - up to 4300 up to 4300

2 approx. 6.8 - up to 4300 up to 3600 -

1 approx. 5.1 all up to 3200 up to 2500 -

6 7

F 9

0999.GB

6.4 Check hydraulic oil level

– Prepare the truck for servicing and maintenance operations (see section 6.1).

– Open the front hood (see section 6.3).

– Check the hydraulic oil level of the hydraulic tank (see section 5).

A

There are markings on the hydraulic tank (see section 5). The oil level must be chek-

ked with the lifting device being lowered.

– If required, top up with hydraulic oil with the required characteristics

(see section 5.1; see table)

A

Mounting is performed in reverse order.

6.5 Check the transmission oil level

– Prepare the truck for servicing and maintenance operations (see section 6.1).

– Open the front hood (see section 6.3).

– Loosen 2 x screws (5) using the key (2).

– Remove carefully the wheel cover (4).

– Check gear-oil level - oil level must reach the filler neck

(see section 5).

– If required, top up with gear oil with the required characteristics (see section 5.1).

A

Mounting is performed in reverse order.

6.6 Exchanging the coarse sieve

– Preparation of the truck for servicing

and maintenance operations

(refer section 6.1).

– Open the front hood (see chapter F,

section 6.3).

– Loosen the screwed connection (6).

– Pull off the connection (7) and remove

the coarse sieve.

– Insert a new coarse sieve.

m

Mounting is performed in reverse order.

m

Tighten screwed connection (6) with

max. 60

+10

Nm.

Marking Litre Lifting heights (h

3

)

EZTZZDZ

Upper edge approx. 10.5 - - - up to 5350

4approx. 10----

3 approx. 8.3 - - up to 4300 up to 4300

2 approx. 6.8 - up to 4300 up to 3600 -

1 approx. 5.1 all up to 3200 up to 2500 -

6 7

Loading...

Loading...