Page 7.6 - 4 COMBIVERT F5-A, -E, -H © KEB, 2012-10

Motor data and controller adjustments of the synchronous motor

dr.26 = EMK

eff

x √ 2

No decimal places can be entered in parameter dr.26 for the EMC. The voltage per 1000 rpm at high-frequency

motors is partly very low, that an integer setting falsies the EMC value. Parameter dr.63 (DSM EMC HR) can

be used for higher accuracy.

In order that there is a downward compatibility to older parameter lists, the parameter can be deactivated with

value "0: off".

The maximum permissible speed which is displayed in ru.79 (abs. speed [EMC]) is also calculated from the

EMC. The maximum DC link voltage, UZKmax, can be found in the power circuit manual.

Max. UDC

link

x 1000 rpm

—————————

dr.26

ru.79 =

DSM stand still current (dr.28)

The standstill continuous current affects the electronic motor protection function (see chapter 7.13.).

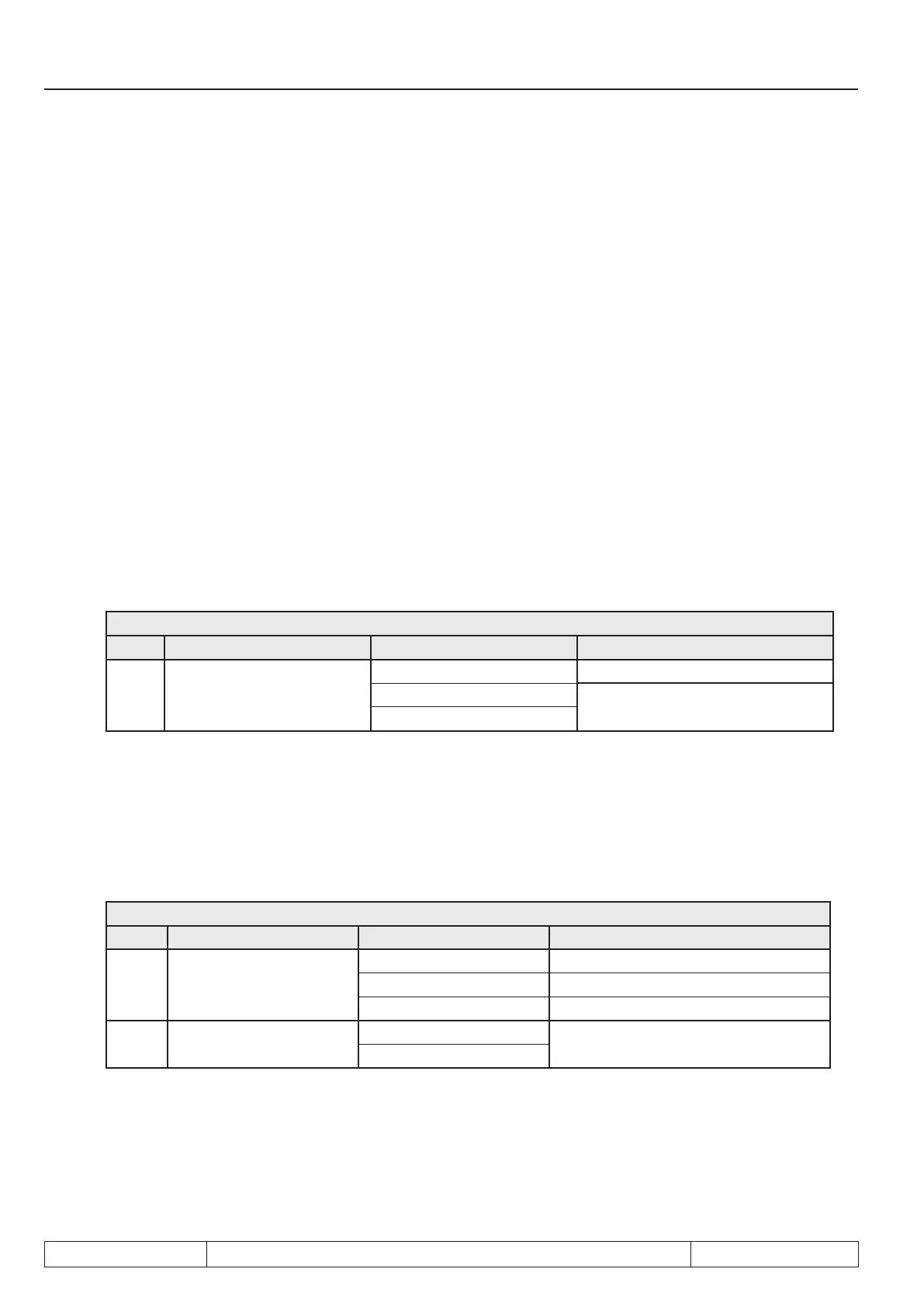

7.6.1.2 Controllerconguration

Parameter cS.00 must set to value 4: "speed control" for closed-loop operation.

cS.00Controllerconguration

Bit Description Value Function

0...3 Control mode

4: Speed control

5: Torque control

(description see chapter 7.7)

6: Torque/ speed

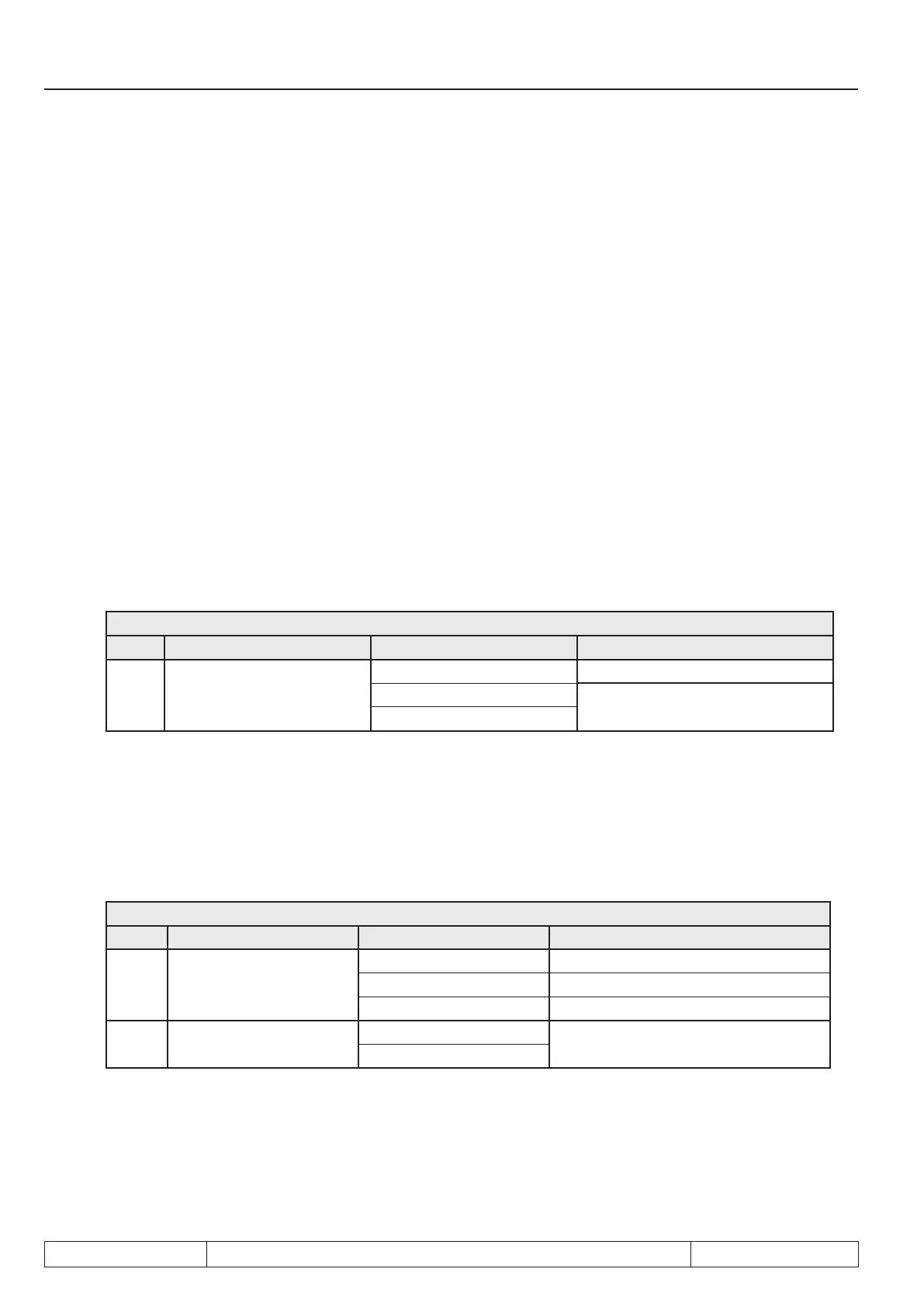

7.6.1.3 Actual value source

The actual value source for speed control must be selected in parameter cS.01 .

Possible values for drives with speed encoder are 0 (speed measurement via encoder interface channel 1) or

1 (speed measurement via encoder interface channel 2).

Description of the correct parameter setting of the encoder interfaces is made in chapter 7.11 "Speed measure-

ment". cS.01 = 2 (calculated actual value) must be selected at operation without speed encoder (only SCL).

cS.01 Actual value source

Bit Description Value Function

0...1 Actual value source

0: Channel 1 Control to encoder interface 1

1: Channel 2 Control to encoder interface 2

2: calculated actual value Control to estimated speed

2 System inversion

0: off

4: An

With activation of the system inversion it is reached that the motor with selected rotation direction "forward"

(e.g. by setpoint- or rotation setting) has the physically direction "reverse" respectively at setting "reverse" the

physical rotation "forward". Precondition is a correct wiring of motor and speed feedback (if available).

Loading...

Loading...