7.12.3.3 Synchronous mode / position normalisation

The channel where the slave receives the master position is selected via parameter PS.01 actual position sour-

ce. This must be encoder channel 2 for most applications. (Off-the-shelf cables and a terminating resistor that

can be switched off exist only for channel 2 ).

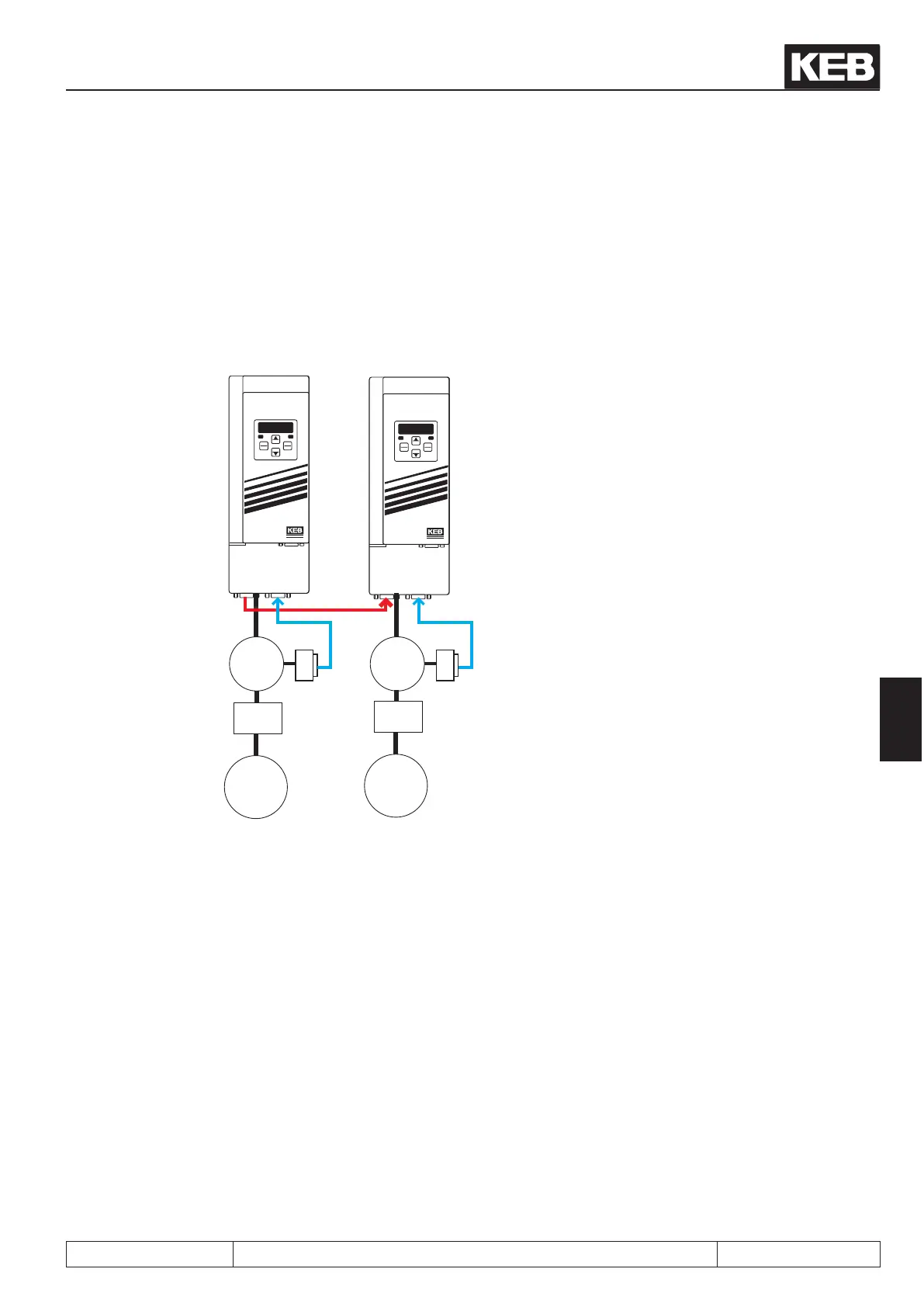

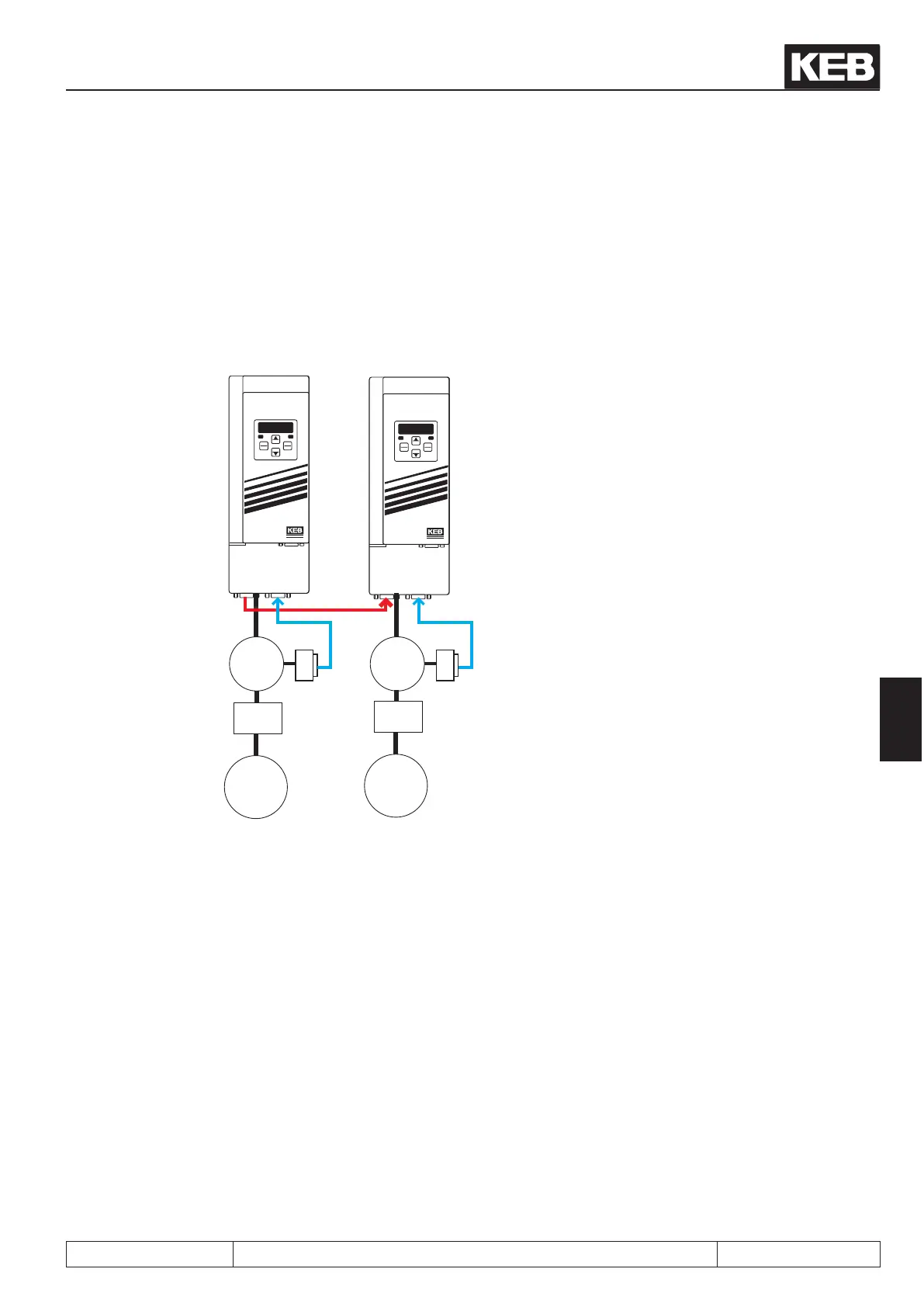

Figure 7.12.3.4 Position normalisation

START

STOP

FUNC.

SPEED

ENTER

F/R

ANTRIEBSTECHNI K

START

STOP

FUNC.

SPEED

ENTER

F/R

ANTRIEBSTECHNI K

X3B X3A X3B X3A

3

~

3

~

Load

i= 5,25

Load

i= 15

speed

closed-loop

master drive

speed

closed-loop

slave drive

forward direc-

tion of rotation

reverse direc-

tion of rotation

The adjoining gure shows a typical

synchronous application.

If the load of the master drive

has travelled one revolution, the load of

the slave should also have travelled one

revolution (in the opposite direction).

This is the case for e.g. printing ma-

chines or

rolling machines.

The slave position (i.e. the number of increments of the slave motor) is displayed in parameter ru.54 "actual

position". In ru.54, one revolution of the slave load corresponds to:

ec.01 "encoder 1 (inc/r)" x gear factor slave

The master position is displayed in parameter ru.56 "set position". The display occurs in increments and is con-

verted to the slave position. The conversion considers the ratio of the increments per revolution of the encoder

and the ratio of the two gear factors. If the master is connected to encoder channel 2, the gear factor of the

slave must be entered in parameter Ec.14 "gear factor 2 numerator" and the gear factor of the master must be

entered in parameter Ec.15 "gear factor 2 denominator" for conversion of the gear ratios.

Since only integer values can be preset, the gear factors must be extended correspondingly

(15 : 5.25 becomes 1500 : 525). Display in ru.56 (master position converted to slave units):

Posi- and synchronous operating

© KEB, 2012-10 COMBIVERT F5-A, -E, -H Page 7.12 - 17

7

Loading...

Loading...