- The synchronisation path is set via parameter PS.05 "start offset", making it difcult to realise an offset

between master and slave at the start.

- Checking whether the synchronisation was successful is not possible. If the slave drive cannot follow the

calculated ramp (e.g., due to reaching the torque limit), the master position is still set to the slave position.

The angle synchronicity is lost thereby (for the example above, the connection to the position of the switch

"activate synchronous running" would be lost). The switching condition "drive running synchronously" is

also still set in spite of the angle error.

- Even if the slave drive can generally follow, system deviations can distort the accuracy of the angle-

synchronous running.

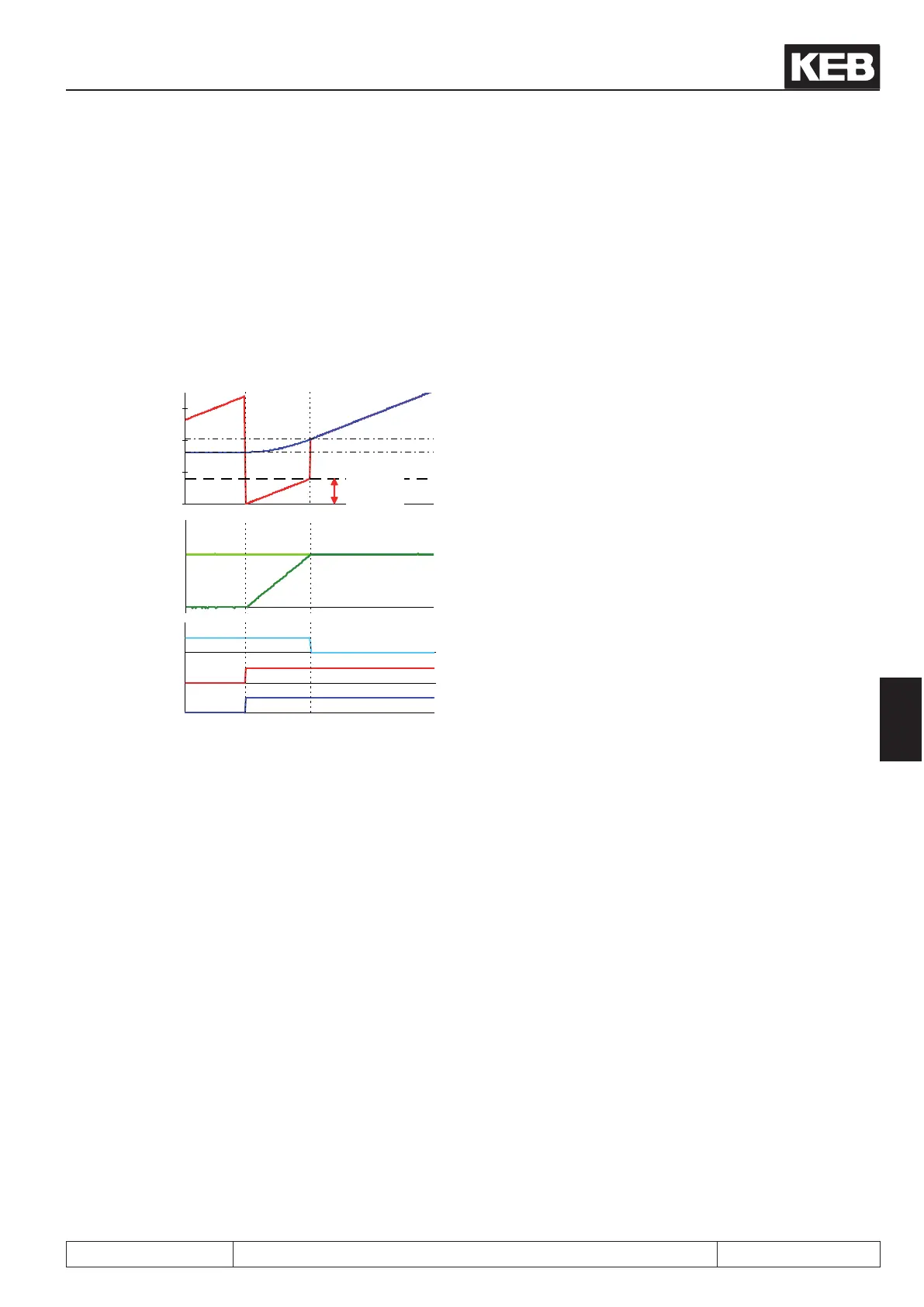

0

PS.05:

Startoffset

3000

2000

1000

1

2

3

5

4

6

7

t

The master position (set position) is set to 0 at the activation

of the synchronous module.

When the master has completed the path programmed in

PS.05, the master position is set to the slave position.

The slave drive calculates the acceleration / deceleration

ramps it needs to reach the master in this time.

The ramp time also depends on the master speed and the

value in PS.05.

After the master has completed the path programmed in

PS.05, the master position (set position) is overwritten with

the slave position (actual position).

1. ru.56: Set position (master position)

2. ru.54: Actual position (slave position)

3. Actual speed master (converted with the gear ratio)

4. Actual speed slave

5. Angle difference > level

6. Drive runs synchronously

7. Activate posi / synrchronous running

Posi- and synchronous operating

© KEB, 2012-10 COMBIVERT F5-A, -E, -H Page 7.12 - 21

7

Loading...

Loading...