W303 should be placed in. For example, if the display

shows between -1200 and +200 counts. jumper W303

should be placed in position C.

7. Place the jumper in accordance with the results of step 6.

8. Replace the electrometer board shield.

9. Turn on the power and allow the instrument to warm up

for one hour before performing the following adjustment.

10. Set the input offset potentiometer (R314) for a reading of

00.00 +1 count on the display.

11. Replace the top cover when the procedure is complete.

7.9 HANDLING AND CLEANING

PRECAUTIONS

When troubleshooting or othenvise working inside the instrw

mat, care should be taken not to indiscriminately touch PC

board traces and open wires to avoid contaminating them

with body oils or other foreign matter. In particular, there are

two areas within the Model 617 that have numerow high im-

pedance nodes where contamination could cause degraded

performance. These include the input amplifier area on the

eiectrometer board and the ranging amplifier section location

on the mother board.

The same general precautions apply when replacing parts in

these areas. When unsoldering and soldering parts, be careful

not to spread the flux around the board to adjacent areas.

After replacing parts, or if contamination is suspected, use the

following procedure to clean the affected area.

1. Using a squeeze bottle, carefully apply clean, uncon-

taminated methanol to the area to be cleaned. Use suffi-

cient solution to throughly wet the circuit board.

2. Using a small, cleati brush, wipe the area thoroughly until

it is free of flux or contaminants. In some cases, it may be

helpful to tilt the board at an angle and brush con-

taminants away from the affected area, allowing con-

taminated residue and methanol to run off the board.

3. Wash the area again with fresh, clean methanol.

4. Once the area is thoroughly cleaned, is should be dryed

with pressurized dry, clean air or nitrogen. Do not use

compressed air from an ordinary air compressor, as oil

particles in the air could contaminate the circuit board.

5. After cleaning or parts replacement check to see that any

components connected to the Teflon insulators are not

physically touching the board or adjacent parts.

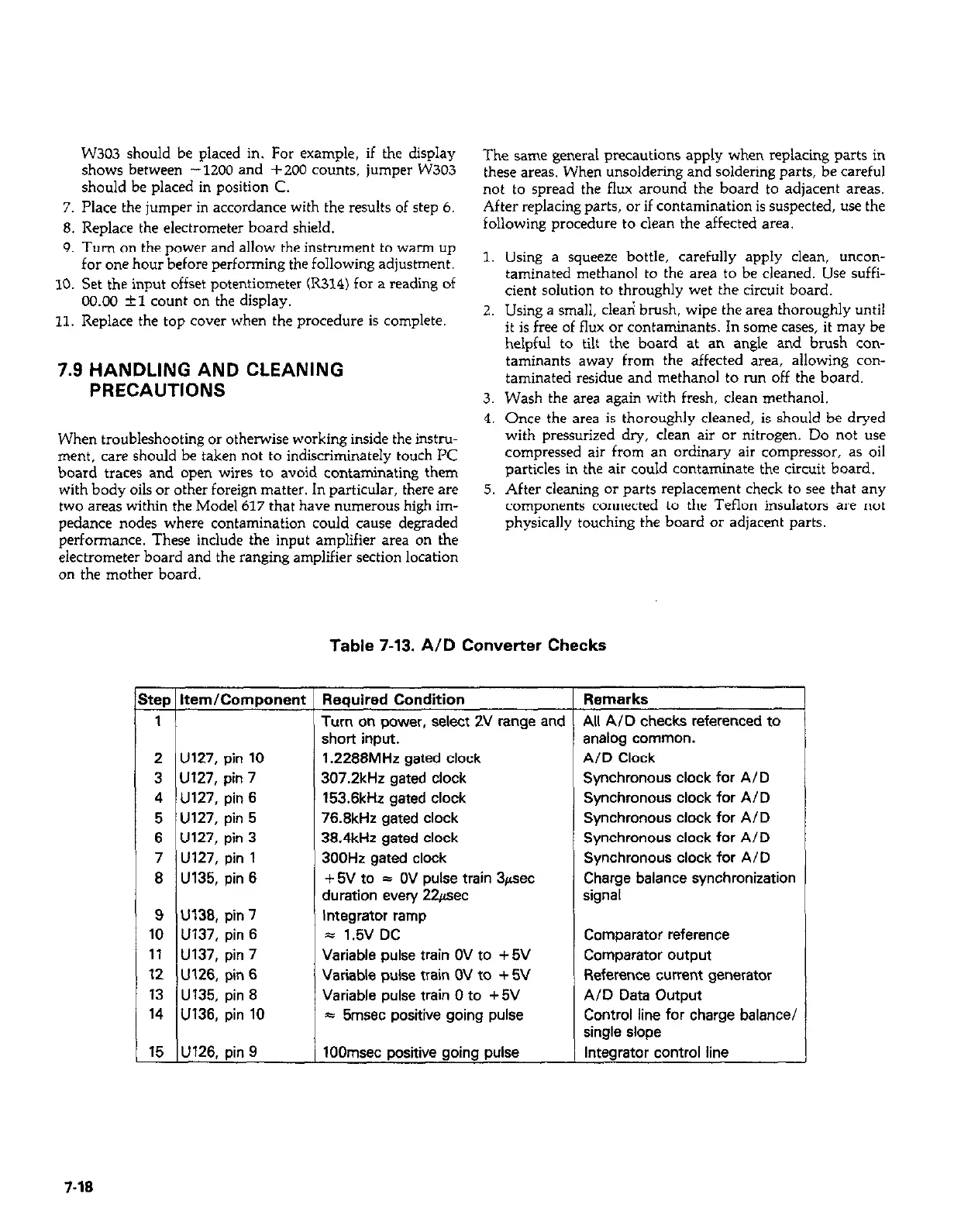

Table 7-13. AID Converter Checks

2 U127, pin 10

3 Ul27, pin 7

4 U127, pin 6

5 U127, pin 5

6 U127, pin 3

7 U127, pin 1

8 U135, pin 6

9 U138, pin 7

10 U137, pin 6

11 U137, pin 7

12 U126, pin 6

13 U135, pin 8

14 U136, pin 10

15 U126, pin 9

Required Condition

Turn on power, select 2V range and

short input.

1.2288MHz gated clock

307.2kHz sated clock

153.8kHz gated clock

76.8kHz gated clock

38.4kHz gated clock

300Hz gated clock

+ 5V to = OV pulse train 3/rsec

duration every 22eec

Integrator ramp

5 1.5V DC

Variable pulse train OV to +5V

Variable pulse train OV to + 5V

Variable pulse train 0 to + 5V

= 5msec positive going pulse

1OOmsec positive going pulse

f

Remarks

All AID checks referenced to

analog common.

AID Clock

Synchronous clock for A/D

Synchronous clock for A/D

Synchronous clock for A/D

Synchronous clock for AID

Synchronous clock for A/D

Charge balance synchronization

signal

Comparator reference

Comparator output

Reference current generator

A/D Data Output

Control line for charge balance/

single slope

Integrator control line

7-18

Loading...

Loading...