MasterTig 535ACDC

Operating manual - EN

To adjust parameters:

1. Go to the Start & stop sequence view.

2. Turn the control knob (1) to browse through the parameters.

3. Select a parameter for adjusting by pressing the control knob button (1).

4. Adjust the parameter by turning the control knob (1).

5. Close the parameter setting by pressing the control knob (1).

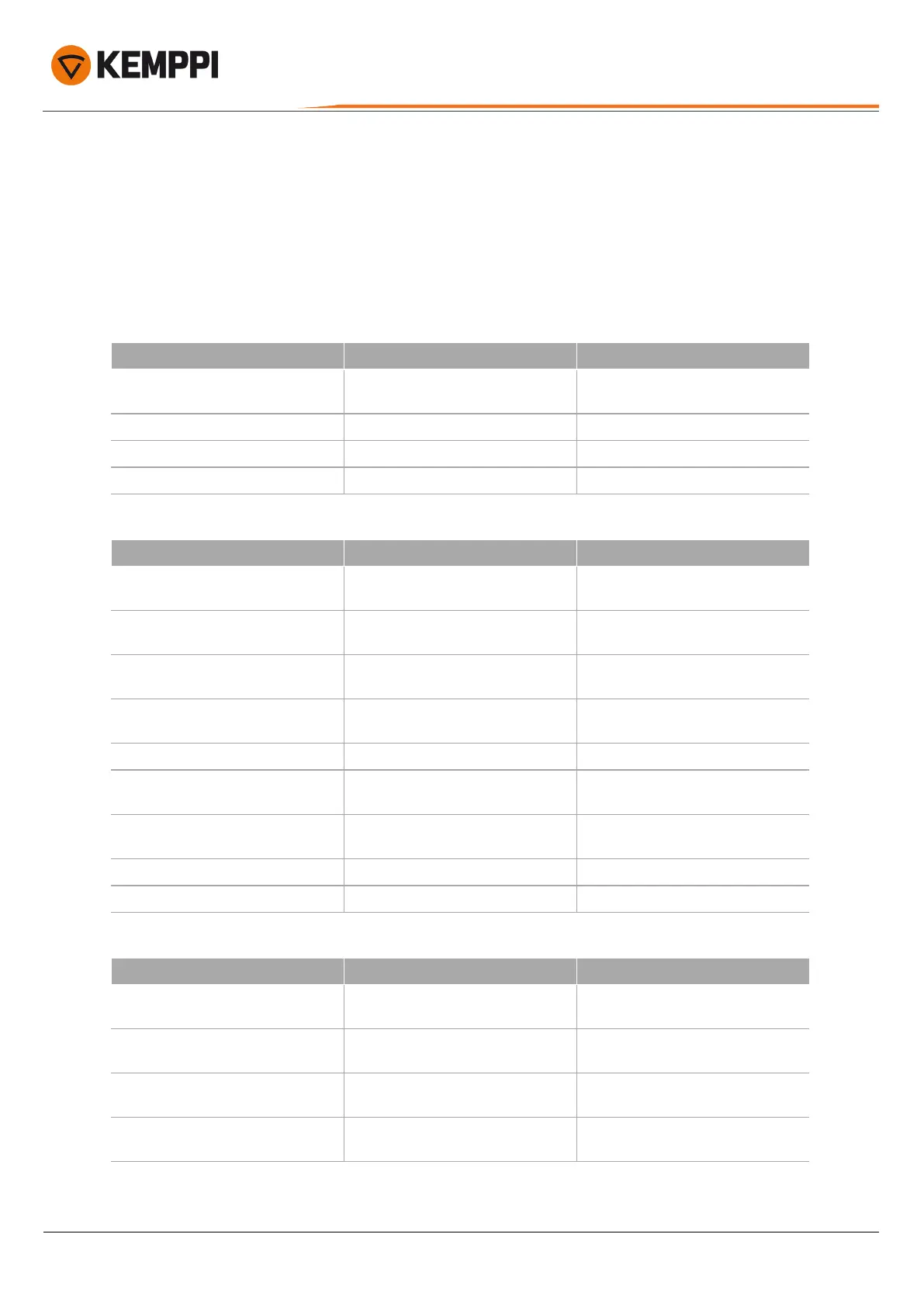

Adjustable parameters in all welding modes:

Parameter Value Note

Trigger logic

2T / 4T / 4T LOG / 4T LOG + Minilog

(Default = 2T)

Welding mode

Continuous / Spot / MicroTack

Welding current

Default = 50 A

Ignition mode

HF (High frequency) / Lift TIG ignition

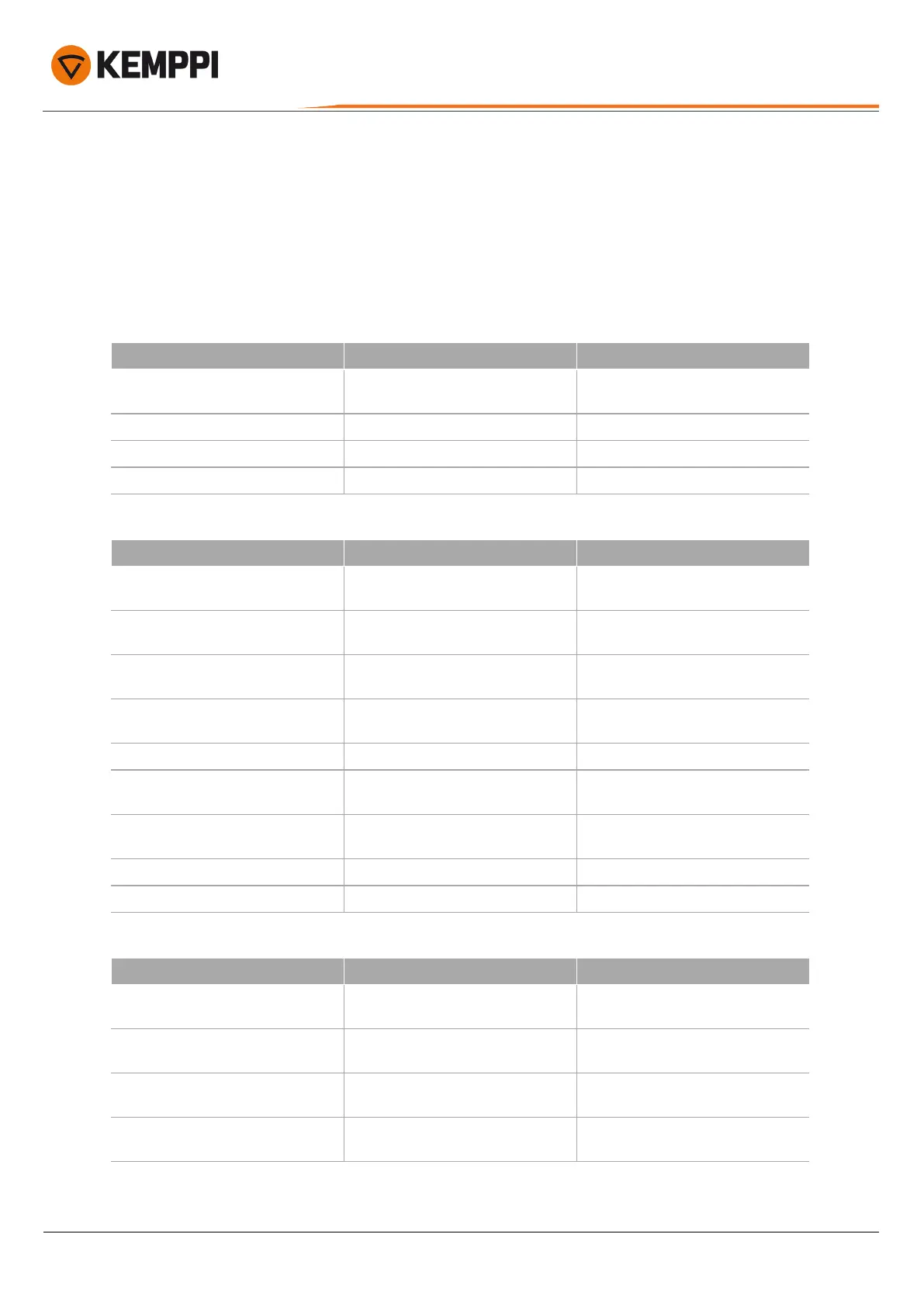

Adjustable parameters in continuous welding:

Parameter Value Note

Pre gas

0.0 s ... 10.0 s, Auto, step 0.1 s (Default =

Auto)

Search arc

OFF / 5 % ... 90 %, step 1 % (Default =

OFF)

Upslope

OFF / 0.1 s ... 5.0 s, step 0.1 s (Default =

OFF)

Hot start level

-80 % ... 100 %, step 1 % (Default = OFF, 0

%)

Hot start time

0.1 s ... 9.9 s, step 0.1 s (Default = 1.2 s) This is not available with 4T trigger logic.

Minilog level

-99 % ... 125 %, step 1 % (Default = OFF, 0

%)

Downslope

OFF / 0.1 s ... 15.0 s, step 0.1 s (Default =

0.1 s)

Tail arc

OFF / 5 % ... 90 % (Default = OFF)

Post gas

0.0 s ... 30.0 s / Auto, step 0.1 s

Adjustable parameters in spot welding:

Parameter Value Note

Pre gas

0.0 s ... 10.0 s, Auto, step 0.1 s (Default =

Auto)

Upslope

OFF / 0.1 s ... 5.0 s, step 0.1 s (Default =

OFF)

Spot time

0 s ... 10 s, step 0.1 s (Default = 2.0 s)

10 s ... 150.0 s, step 1.0 s

Downslope

OFF / 0.1 s ... 15.0 s, step 0.1 s (Default =

0.1 s)

© Kemppi

40

1921940 / 2140

Loading...

Loading...