TM

Model 3000M0188-01

Rev. 6/11 7-17

Lubrication and Maintenance

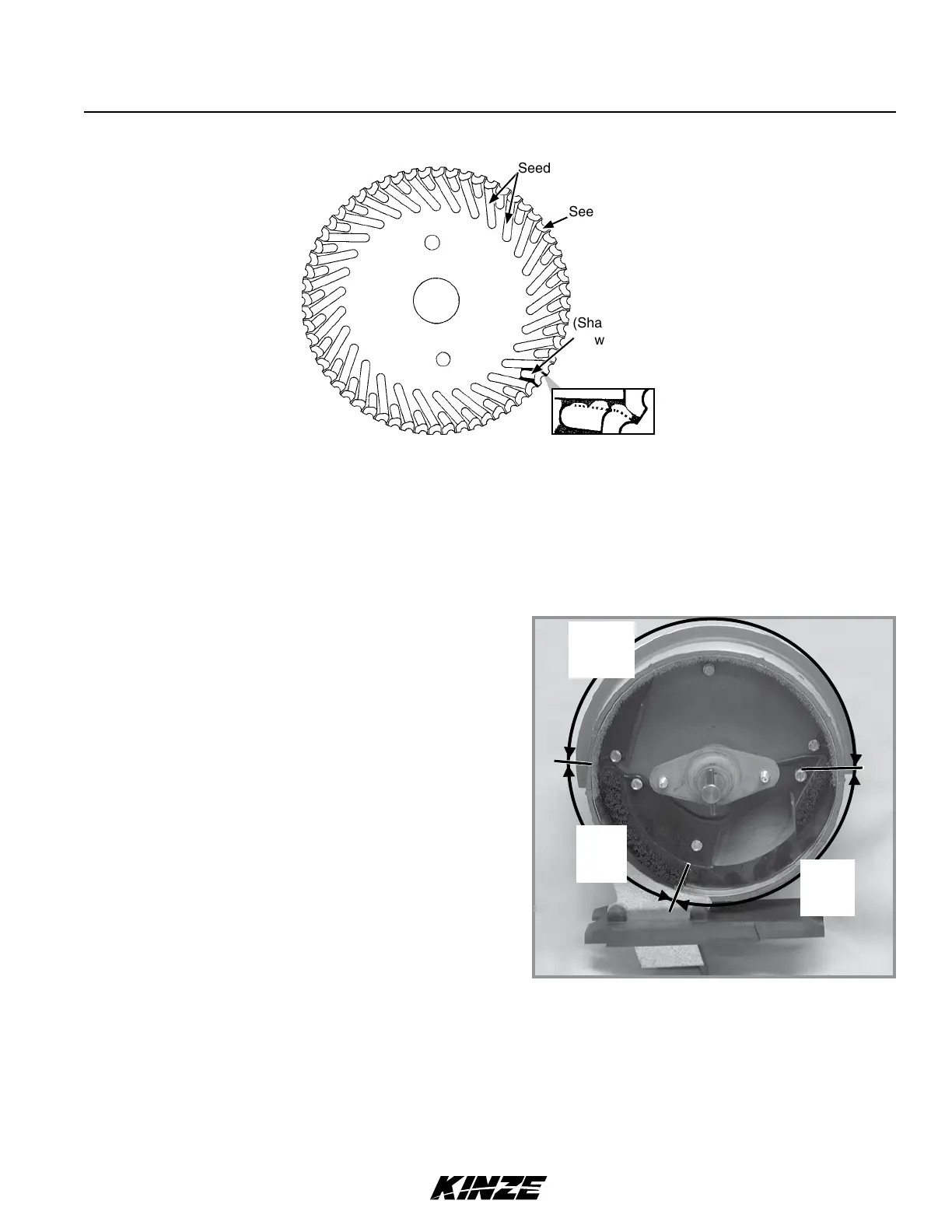

Seed Disc Wear

Most seed disc wear is found in the agitation groove area (area between seed loading slots). Wear affects planting

accuracy at high RPM. Lay a straight edge across disc surface at agitation groove area and measure gap between disc and

straight edge. If agitation groove areas are worn in excess of .030" (7.6 mm) and accuracy starts to drop off at higher meter

RPM, replace seed disc.

Estimated seed disc life expectancy under normal operating conditions is approximately 200 acres (81 hectares) per

row. Severe operating conditions such as dust, lack of lubrication or abrasive seed coating could reduce seed disc life

expectancy to under 100 acres (40.5 hectares) per row.

Agitation

groove area

(Shaded area)-

where most

wear

occurs

Seed loading slots

Seed pocket

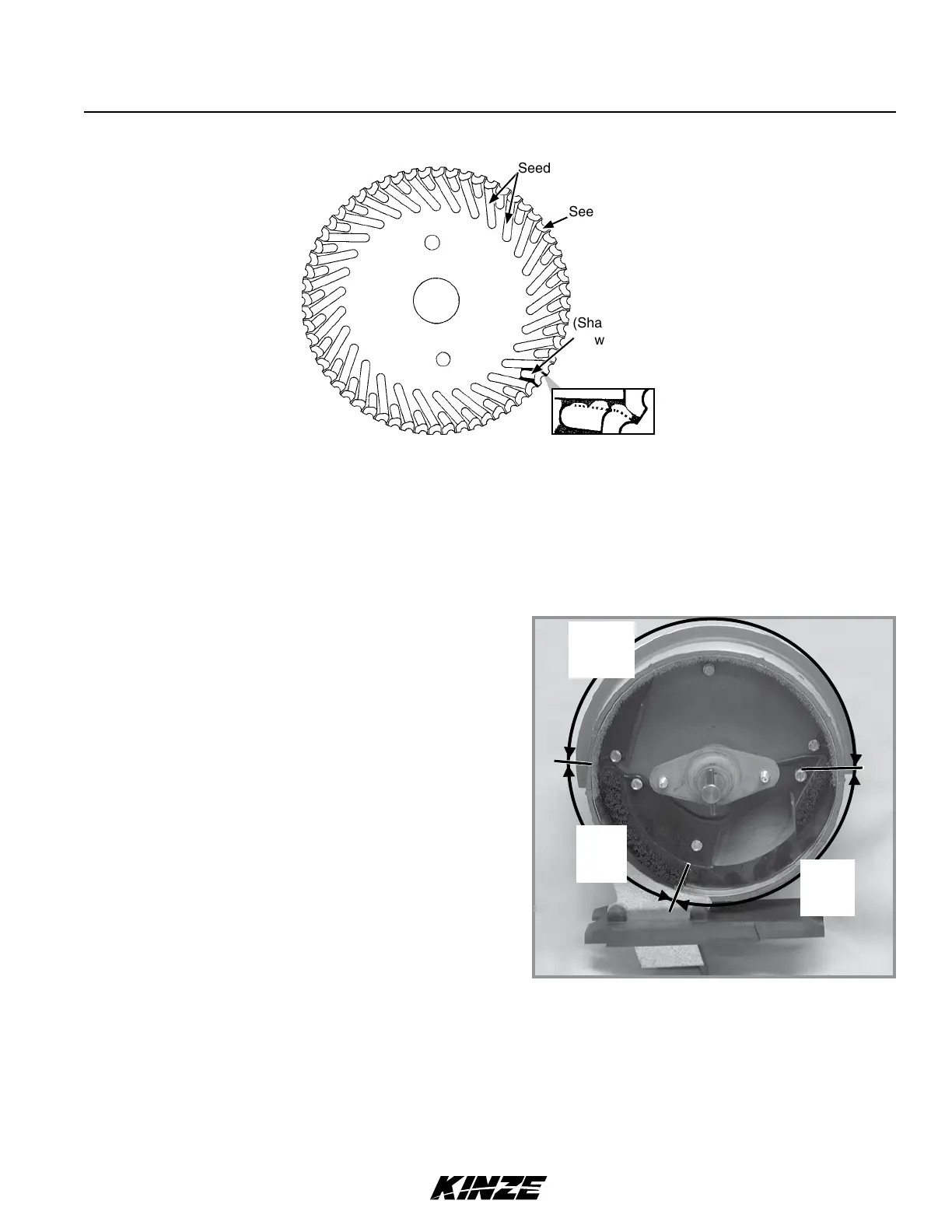

Upper brush holds seed in seed disc pocket in seed

retention area.

Brush must apply enough pressure against seed in

seed disc pocket as disc rotates through seed retention

area to prevent seed from dropping out of disc pocket. A

damaged spot, excessive brush wear, or foreign material

lodged in brush may greatly reduce meter performance.

Replace upper brush at 120-400 acres (49-162 hectares)

per row of use or sooner if damage or excessive wear is

found.

Installation Of Upper Brush

Position upper brush into inner perimeter of seed

retention area. Make sure base of brush is tight

against bottom of meter housing. Install brush retainer

and three hex head screws. Tighten center screw first,

left screw second and right screw last.

NOTE: Use GD11122 upper brush retainer for

soybean and cotton discs. Use GD8237 upper

brush retainer for milo/grain sorghum discs.

GD11122 brush retainer shown.

Upper Brush

Seed

retention

area

Seed

drop

are

a

Seed

loading

area

Loading...

Loading...