26

(8) Insert the bearing bearer (integrated with

the pinion) to the body.

•

Make sure there is no gap between the junction faces of

the bearing holder and body.

•

Be careful not to scratch the oil seal with the gear part of

the pinion.

•

Apply screw lock on the 3 socket bolts and tighten them.

•

Apply molybdenum disulde grease Molytherm No.2

lightly and evenly onto the spline part of the pinion.

Molytherm No.2 : 2g

Tightening torque M5 : 8.4 N·m

M6 : 10.8 N·m

(7) Insert the pinion (with the bearing) to the

bearing holder.

•

If it is difcult to insert the pinion, hammer it gently with a

plastic hammer.

Pinion

Bearing

Bearing holder

Oil

Socket

bolt

Bearing

holder

Spline part

Grease

Torque

Lock

• Apply the specified grease on the spline part of the pinion.

Failure to follow this instruction may cause a falling load due to wear or damage of parts

and result in death or severe injury.

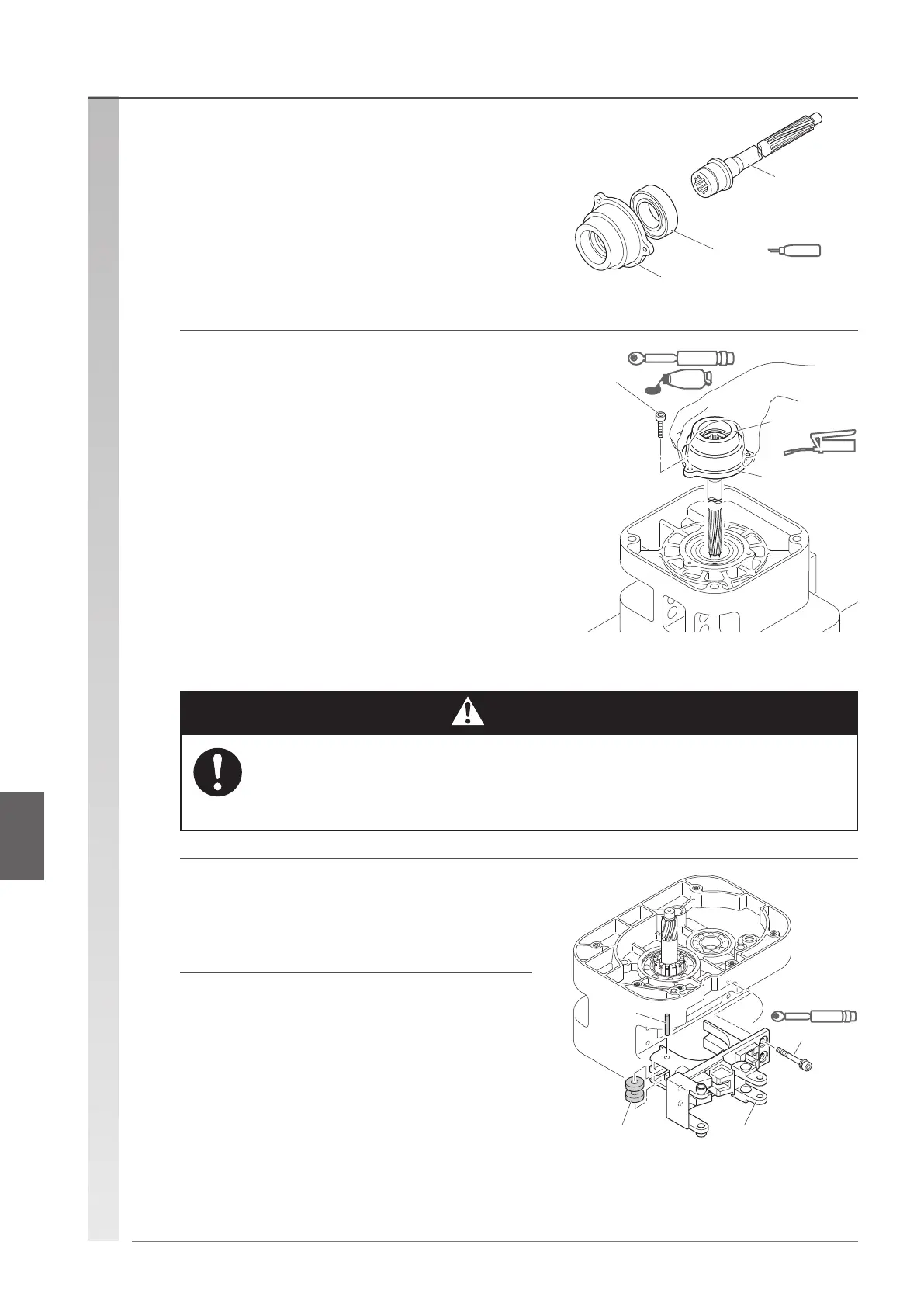

(10) Install Chain Guide A to the body with the 4

socket bolts.

•

Tighten the socket bolts at the following torque.

•

Chain Guide B is fastened together for Basic main bodies

B and C.

Tightening torque M6 : 10.8 N·m

M8 : 37.2 N·m

Chain Guide A

Socket bolt

Guide roller

Roller

pin

Torque

(9) Install the guide roller to Chain Guide A with

the roller pin.

•

Guide roller is provided for Basic main bodies D, E, and F.

Reassembly procedure (continued)

Mandatory

Danger

Reassembly procedureAssembling the body

Loading...

Loading...