36

Reassembly procedure (continued)

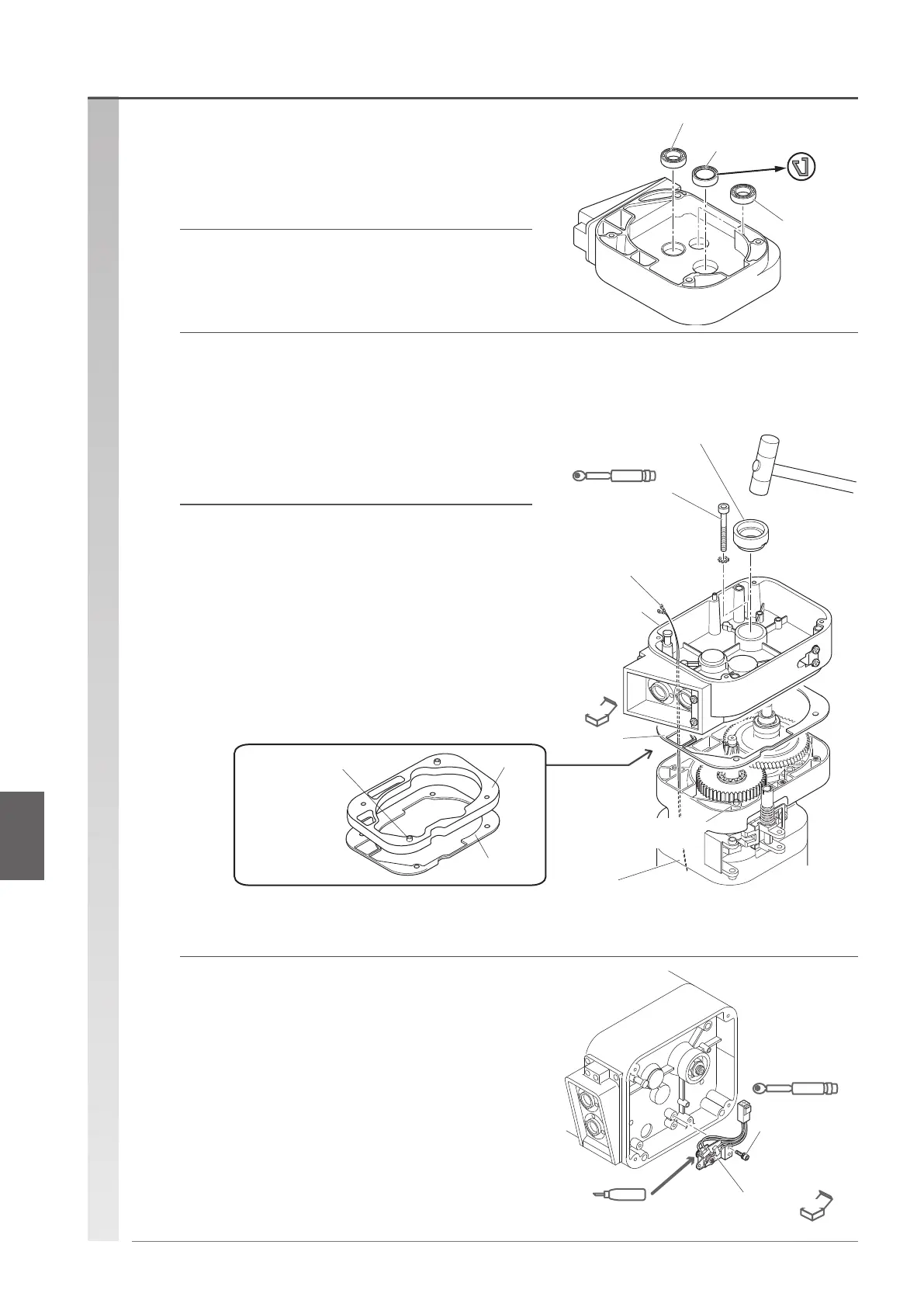

(3) Press-tthebearingforthepiniontothe

gear case using a proper jig.

(6) Mount a new Packing G on the body, and

install the gear case by hammering it with a

plastic hammer.

•

At the same time, install the 2 set pins.

•

Be careful so that the lead wire won't get caught.

•

Temporarily install the gear case with the 4 socket bolts

(5 for F type), and tighten them sequentially, alternating

diagonally.

•

For Friction clutch with mechanical brake specication,

install Spacer M with Packing G between Gear case and

the body.

Tightening torque M6 : 10.8 N·m

M8 : 37.2 N·m

Toothed lock washer : Yes

Socket bolt (x4)

Friction plug

* (x5) for F type

Gear case

Lead wire

Body

Set pin (x2)

(Another one exists in the

opposite side, on the

diagonal line.)

NEW

Torque

Packing G

Install it while

hammering

around the pin

charging part

gently.

(4) Install the oil seal to the gear case using a

proper jig.

(5) Install the friction plug by hammering it with

a plastic hammer.

Bearing

Oil seal

Cross-sectional

shape

Bearing

(triple reduction

specification

only)

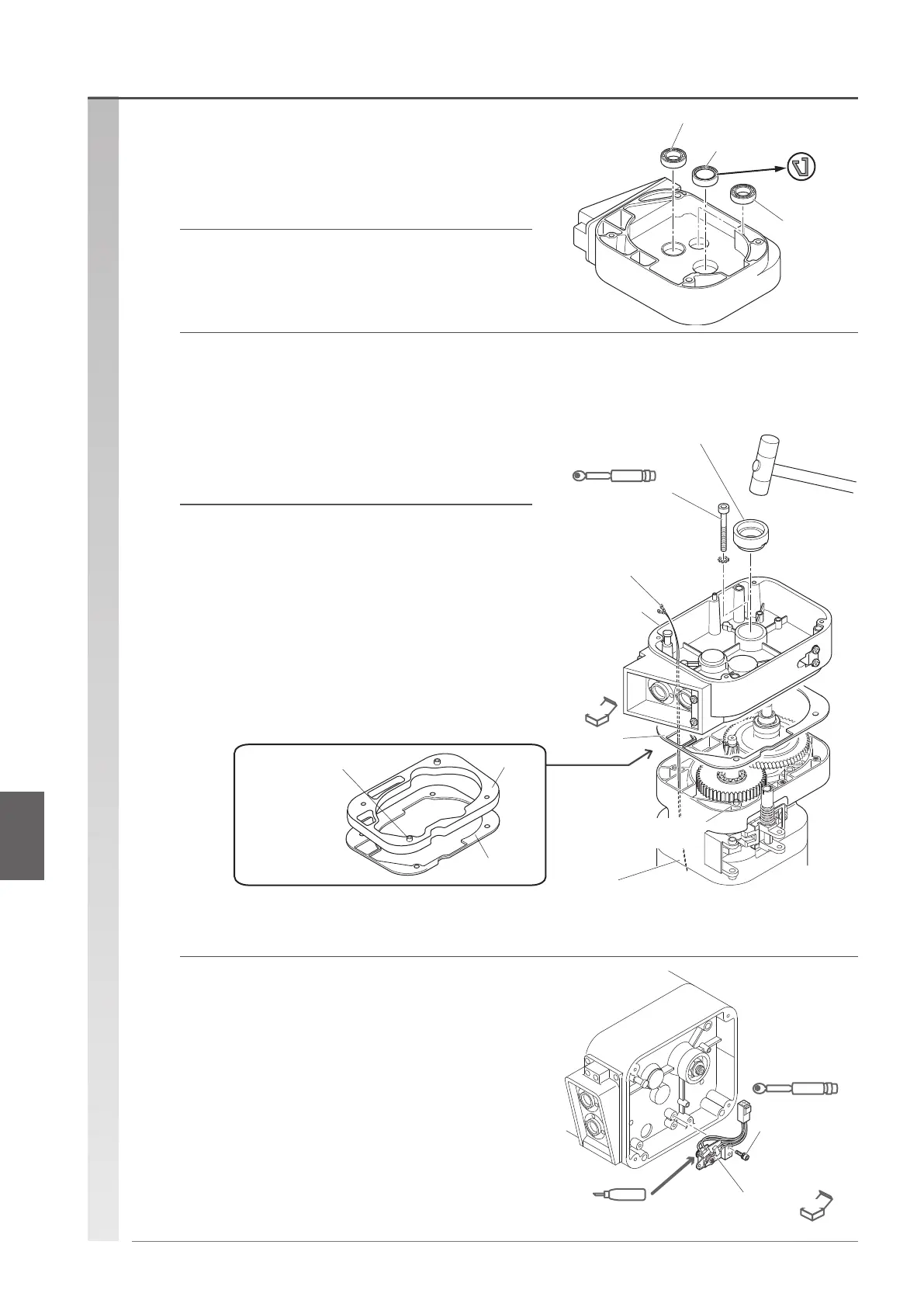

(7) Install the limit switch from the gear case

side (inside of the panel plate) (if removed).

•

Replace O ring attached to the shaft of the limit switch

with a new one and apply oil to it.

•

Align the shaft salient of the limit switch to the notch of the

lever pin when inserting it.

•

Insert it gently not to scratch the O ring.

•

Perform wiring of the limit switch.

After installation, move the limit lever manually and check if

it performs follow-up operation.

Tightening torque M6 : 10.8 N·m

Spring lock washer : Yes

Limit

switch

Apply oil.

Socket bolts

(x3)

Install it in advance.

NEW

Torque

Oil

Spacer M

Packing G

Set pins (two locations)

Another one exists

in the opposite side,

on the diagonal line.

Reassembly procedureAssembling the gear parts

Loading...

Loading...