KMS MP25(M)/MA25(M) manual Version 4.2

20

Engine load sensor calibration:

The engine load sensor connected to the system will have to be calibrated.

The range within which the sensor operates can be set here. A load sensor issues a voltage of 0 to

5V. The range is divided into 8 bits (256 steps). In practice a load sensor does not run through its

full range. For this reason, the upper and lower limits must be set, so that the 16 columns in the

spreadsheets can be best utilized.

There are two ways of calibrating the load sensor:

➢ Automatic calibration

➢ Manual calibration

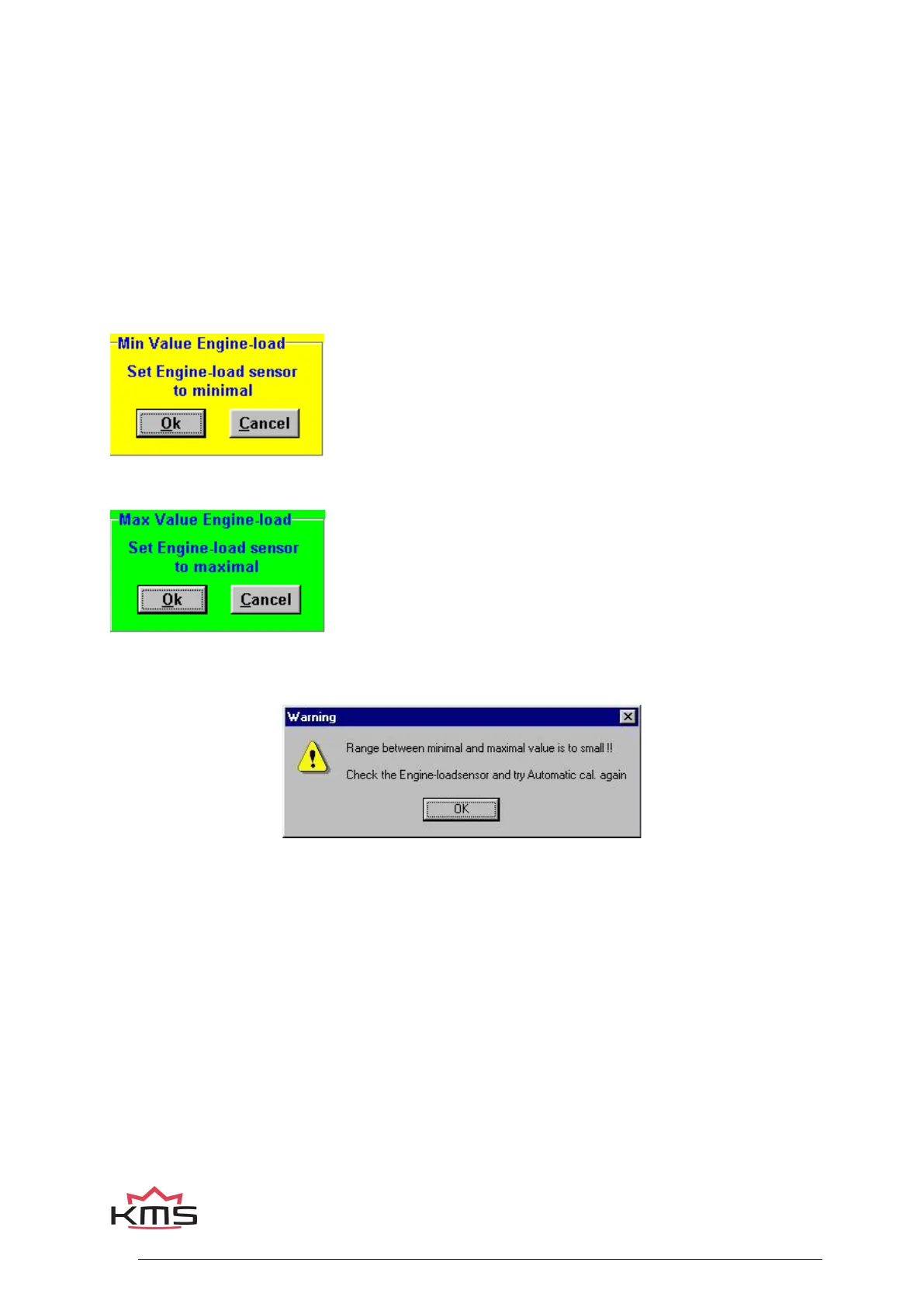

Automatic calibration. When a throttle valve potentiometer is used, it is easy to opt for automatic

calibration. Select 'Automatic cal.' and then keep the throttle valve in rest position, pressing OK.

Then turn the throttle valve to full load and press OK again.

The minimum and maximum values of the throttle positions will now be shown.

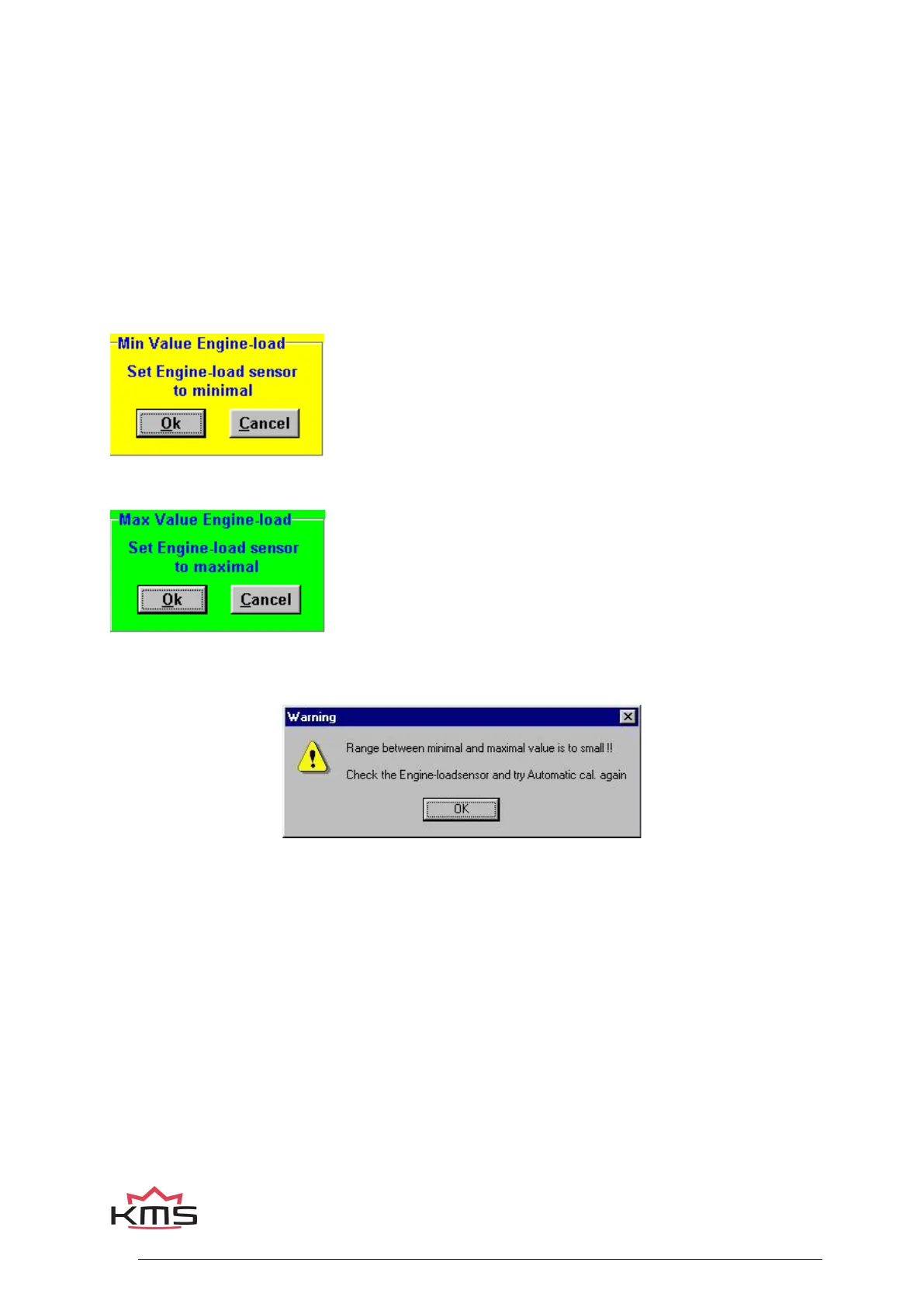

A warning will appear if automatic calibration cannot be finished correctly. For possible causes, see

'Fault tracing'.

Manual calibration. When a map sensor or an air mass sensor is used, automatic calibration is not

easy, because the minimum and maximum output signals of the sensor are not known before the

engine has run. We recommend filling in the figures by hand, making sure that the output signal of

the sensor under any engine operating condition is between the two figures set.

Tip: first set the minimum value 15 and the maximum value 250. If you use a KMS 400 kPa Map

sensor there are recommended settings for the calibration on the datasheet of the sensor.

Loading...

Loading...