KMS MP25(M)/MA25(M) manual Version 4.2

61

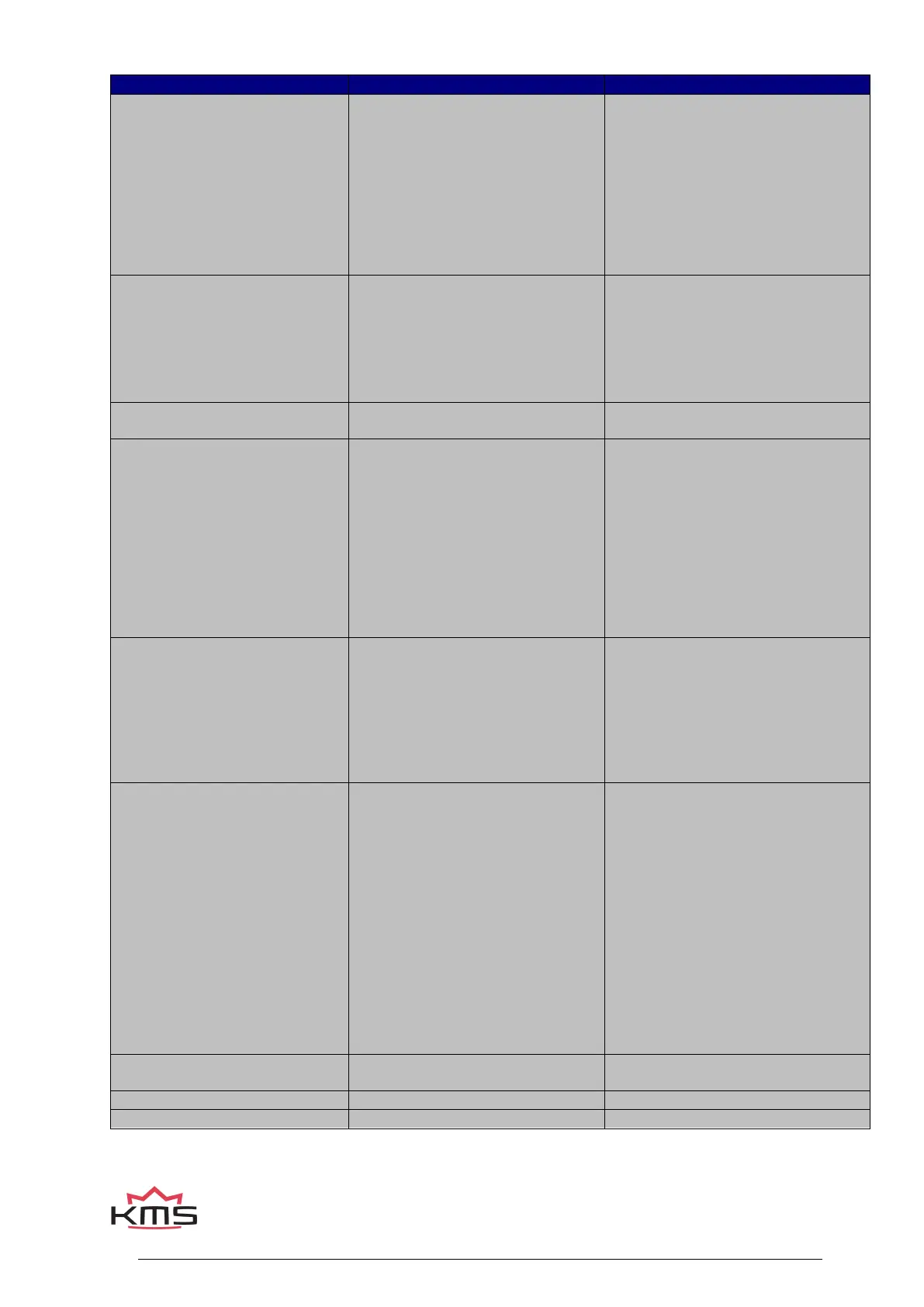

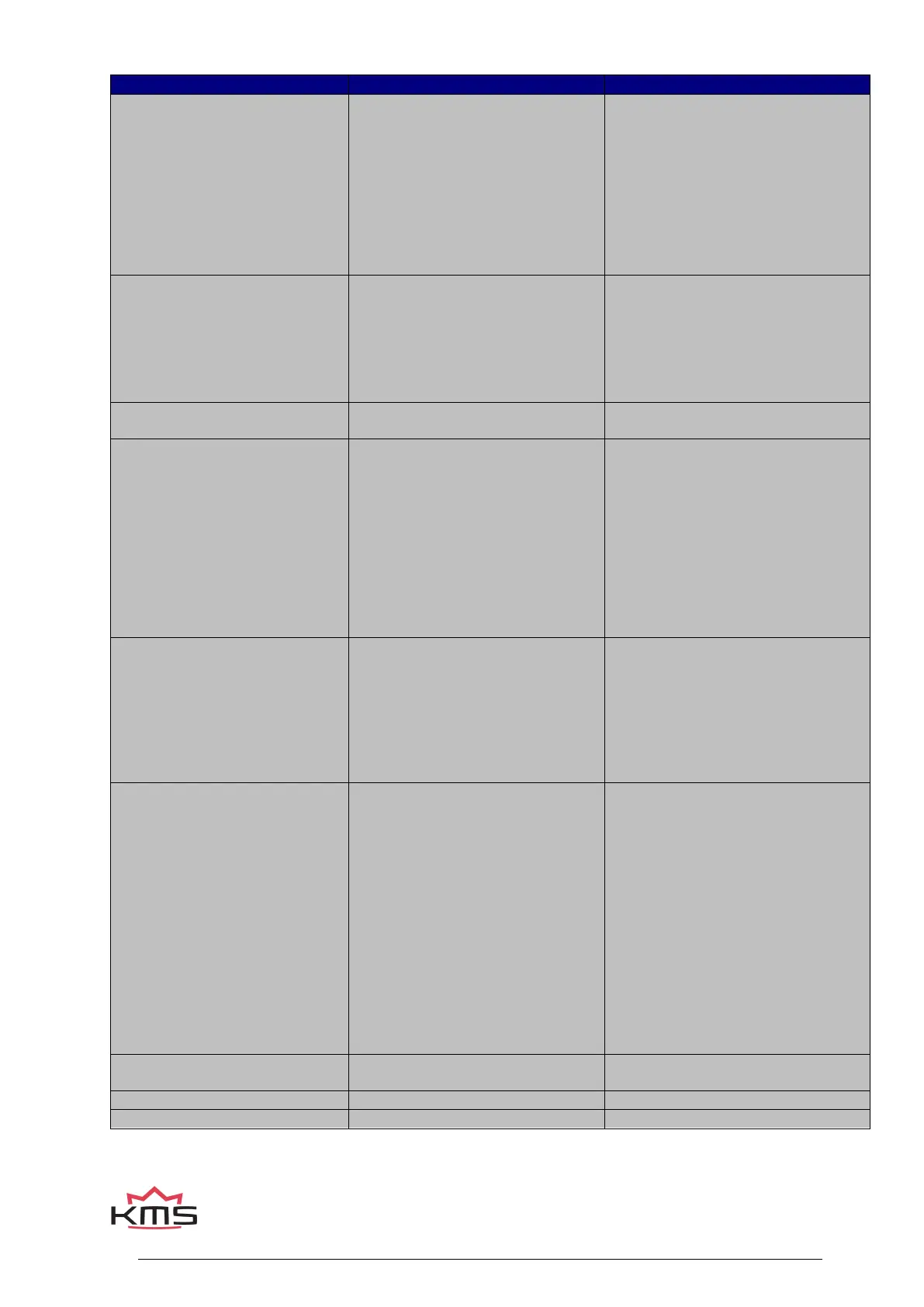

6 Fault tracing

No communication between PC

and system

- No power supply to the system

- Defective or incorrect

communication cable

- Cable connected to wrong COM

port (standard is COM3)

- Switch the contact on or check the

fuse

- Use a USB A Male – USB B Male

data cable

- Connect cable to COM3 or select

another COM port; see section

3.2.4.1.17 Communication port

- No engine speed signal

- Crank Type set is not correct

- Start-up menu settings are not

correct

- Check the sensor and wiring

- See section 3.2.4.1.1 RPM pickup

- Set duration of injection to the

correct value

Poor engine starting when the

engine is cold

- Engine temperature correction

table not correctly set

- Set correction table correctly

Poor accelerator to engine

response

- Incorrect setting of acceleration

enrichment

- Defective engine load sensor

- Engine load sensor not calibrated

- Adjust values in throttle pump

effect menu

- Check whether the engine load

indicated on the dashboard changes

evenly when the accelerator is

slowly depressed

- See paragraph 3.2.4.1.3 Engine

load sensor

Temperature reading gives

incorrect value

Temperature reading gives --- in

the communication bar

- Wrong type of NTC temperature

sensor

- Sensor not connected or short

circuit in sensor wiring

- Fit the correct temperature

sensor; see the Appendix about

sensors on the CD-ROM for the

correct type

- Check the wiring

Auto calibration gives message

'warning range too small'

Auto calibration gives message

'warning signal reversed'

Auto calibration gives message

'engine load sensor not

connected'

- Sensor range too small or

potentiometer connected

incorrectly

- Throttle valve potentiometer

turns in the wrong direction

- The engine load sensor signal

does not change

- Interruption in potentiometer

signal wiring

or potentiometer does not turn

when the throttle valve is opened

- Check the wiring

- Fill in the values of the engine

load sensor manually

- Interchange the earth and 5V

wiring of the potentiometer

Only coils 1-4 give ignition

- Dis coil box not ticked

- See paragraph 3.2.4.1.1 RPM

pickup

Loading...

Loading...