SECTION 9

HYDRAULIC SYSTEM

Jan 2003

p. 9-4

80073463

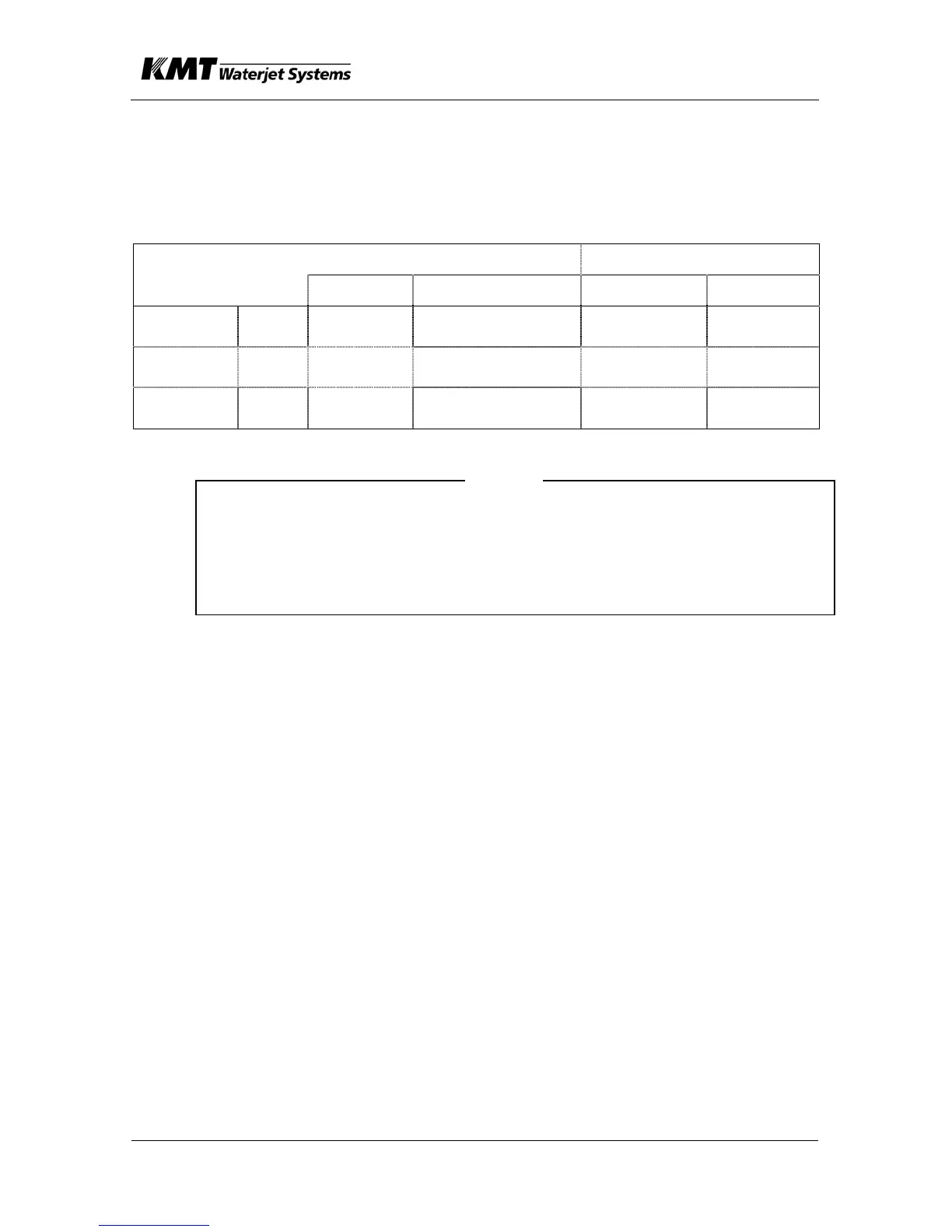

9.2.2 Hydraulic System Pressure Protection

Besides the HI-LOW Pressure Control Valves, the hydraulic system

pressure is limited by the main relief valve (3). The operating hydraulic

pressure is indicated by hydraulic gage (4).

Pressure Adjustment

Hyd. Pressure Bar (psi)

Control Valve

Increase Decrease Maximum Minimum

High

Pressure

1 Clockwise Counterclockwise 207 (3,000) 1.7 (25)

Low

Pressure

2 Clockwise Counterclockwise 103 (1,500) 1.7 (25)

Main

Relief

3 Fixed Fixed 234 (3,400)

(Not

applicable)

NOTE

Do not adjust the HI pressure control to pressures greater than

207 bar (3,000 psi). Doing so will cause the main relief to open

limiting hydraulic pressure to 234 bar (3,400 psi). Also due to

excessive opening of the main relief valve will result in

significant wasted heating of the hydraulic oil, and the decrease

of water flow performance.

9.3 Motor/Hydraulic Service Maintenance

The hydraulic oil filter should be checked daily and replaced if the

pressure gage reads over 40 psi. The hydraulic oil should be replaced

every 2000 hours or yearly, whichever occurs first. For hydraulic oil and

filter maintenance, see Section 10, Recirculation System.

The hydraulic system components that require periodic maintenance are

the motor and the manifold. The motor needs to be serviced every 5000

hours of use. The operating pressure settings of the manifold needs to

be checked daily and adjusted if necessary.

Recommended Tools: Manual Grease Gun

Open End Wrench 14mm (9/16”)

Rags

Parts: Bearing Grease, SRI #2 or equivalent

Loading...

Loading...