SECTION 7

HIGH PRESSURE WATER

May 2003

p. 7-22

49831951

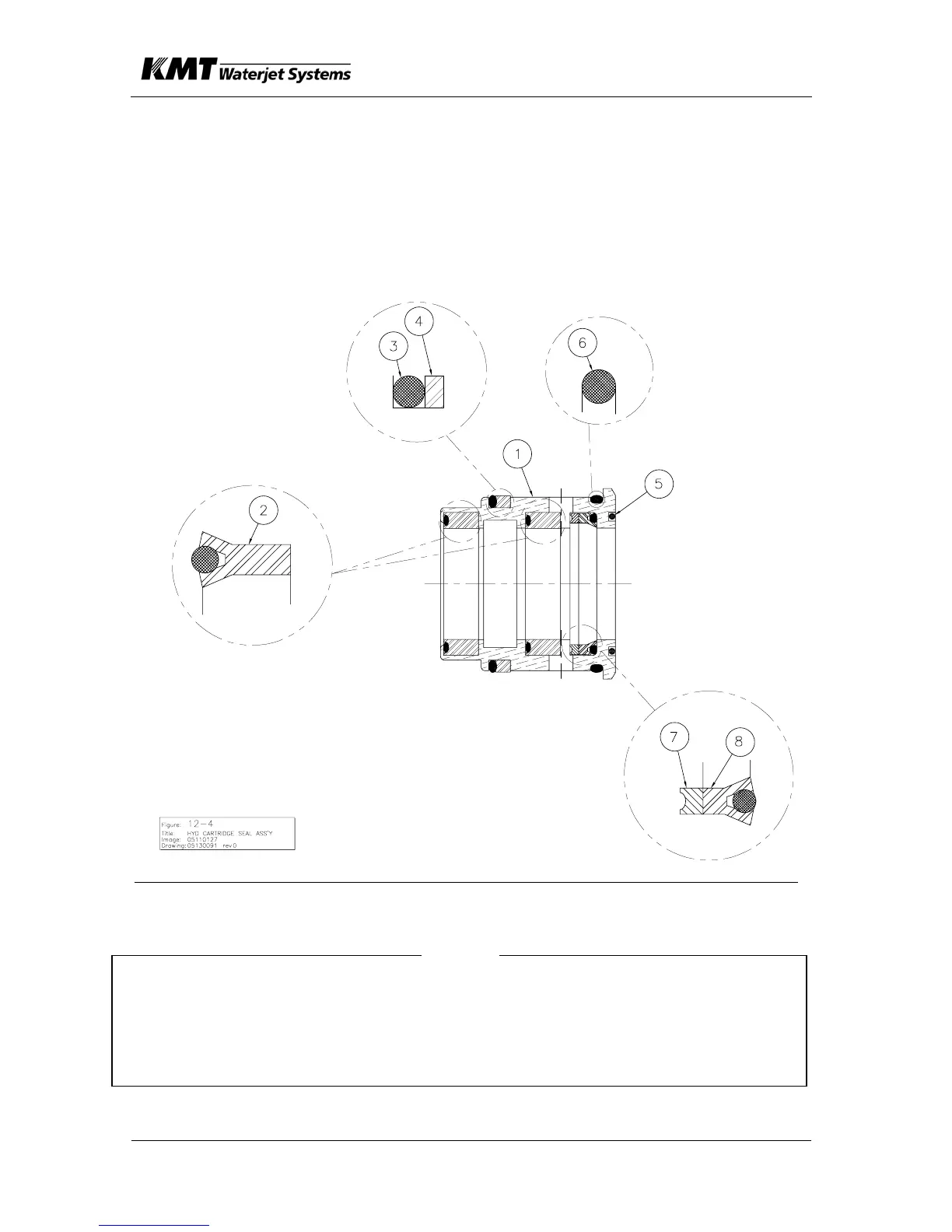

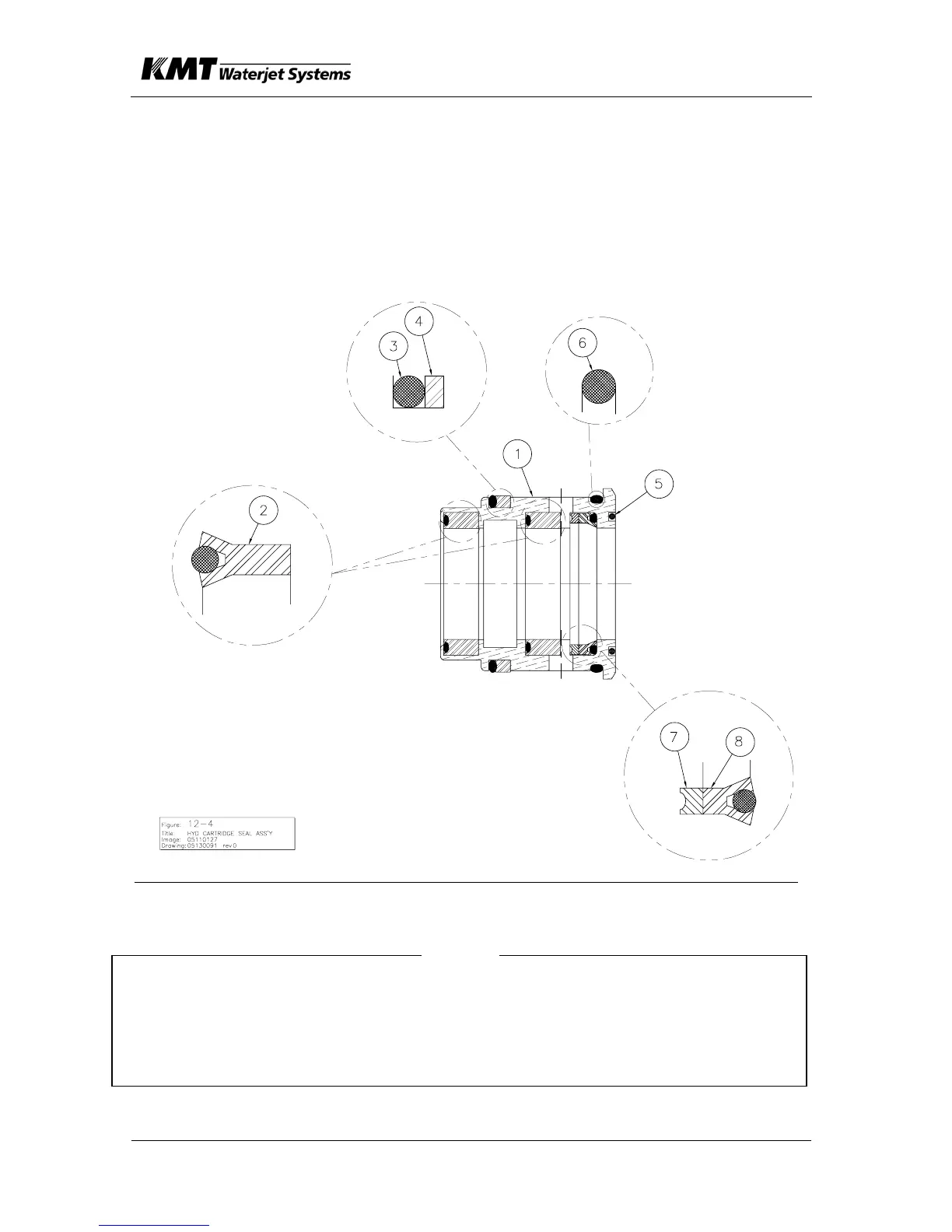

7.3.6 Hydraulic Seal Cartridge

Carefully remove worn seals and O-rings from cartridge by pushing them with a

dowel or similar object. Remove seals positioned close to the open ends first,

working toward the interior. Examine seals for unusual wear, deformation or

cuts. Note any unusual buildups of solid material or debris causing possible

leak paths.

Examine the cartridge body (1) surfaces for scratches, signs of metal-to-metal

contact, deformation or other unusual wear.

Item Description

(1) Cartridge Body (2) U-cup Seal (3) O-Ring

(4) Back-Up Ring (5) O-ring (6) O-Ring

(7) Back-Up Ring (8) U-cup Seal

NOTE

It is important to examine the inside diameter surfaces of cartridge seal grooves

for scratches, especially any scratches in the axial direction that might offer a

leak path. Use caution during seal removal and installation to avoid scratching

these surfaces. Do not use metal screwdrivers, wires, etc. to remove inside

diameter seals. Plastic or wood should be used for seal removal and

installation.

Loading...

Loading...