TP-6322 9/0426 Section 4 Troubleshooting

4.10 Normal Source Sensing

Follow this section when the system fails to recognize

the normal power source as available by lighting the NA

LED, or when it fails to recognize normal power source

failure.

This section requires a voltmeter with a minimum

accuracy of ±1% on the scale being measured.

Initial Normal Source Sensing Troubleshooting

Use this section to initially troubleshoot normal source

sensing. This procedure requires normal source

availability.

1. Disconnect all power sources.

2. On single-phase switches, check for continuity

between terminals GND and 3PH on TB2 on the

controller assembly. If the circuit is open, install a

permanent jumper between these terminals, then

reapply power and test the system.

3. On three-phase switches, disconnect the three-

phase module from terminals GND and 3PH on

TB2 on the controller assembly and install a

temporary jumper between these terminals on the

controller assembly. Remove the temporary

jumper and reconnect the three-phase module

when normal source sensing troubleshooting and

testing is complete.

4. Disconnect the normal source. If the NA LED

remains lit for more than a few seconds, replace the

controller assembly.

5. Reconnect the normal source and check for

nominal line voltage on phase NA-NC on terminals

P1-12 and P1-15 on the controller assembly.

a. If voltage is not present on phase NA-NC on P1

on the controller, check for voltage on lugs NA

and NC on the contactor assembly. If voltage is

not present on the lugs, check the normal

source and the normal source wiring and circuit

breaker. If voltage is present on the lugs, check

the contactor wiring harness connections from

the lugs to the controller assembly.

b. If the voltage on phase NA-NC on P1 on the

controller exceeds the single-phase pickup

voltage specification in Figure 4-10 then the NA

LED on the controller assembly should light;

replace the controller assembly if the LED does

not light.

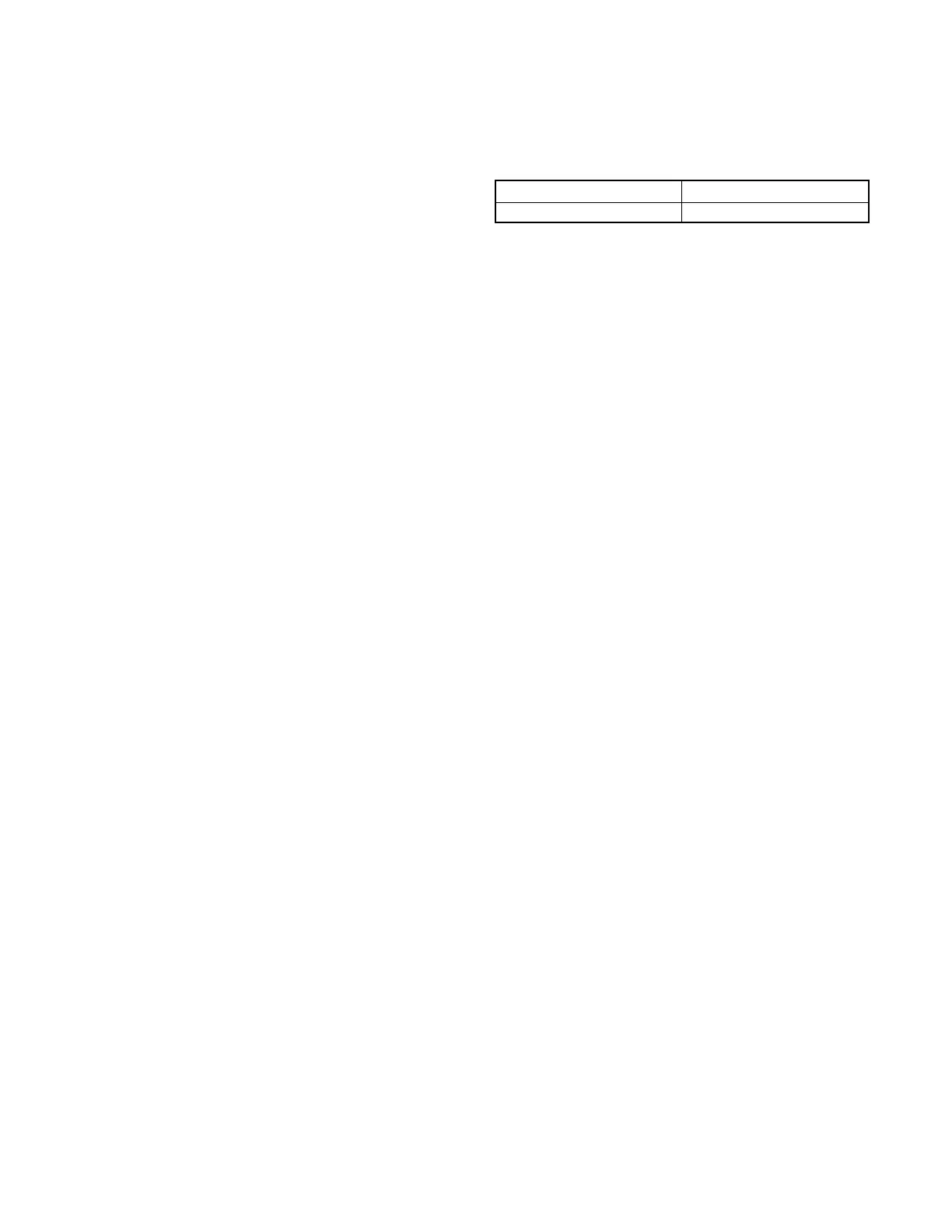

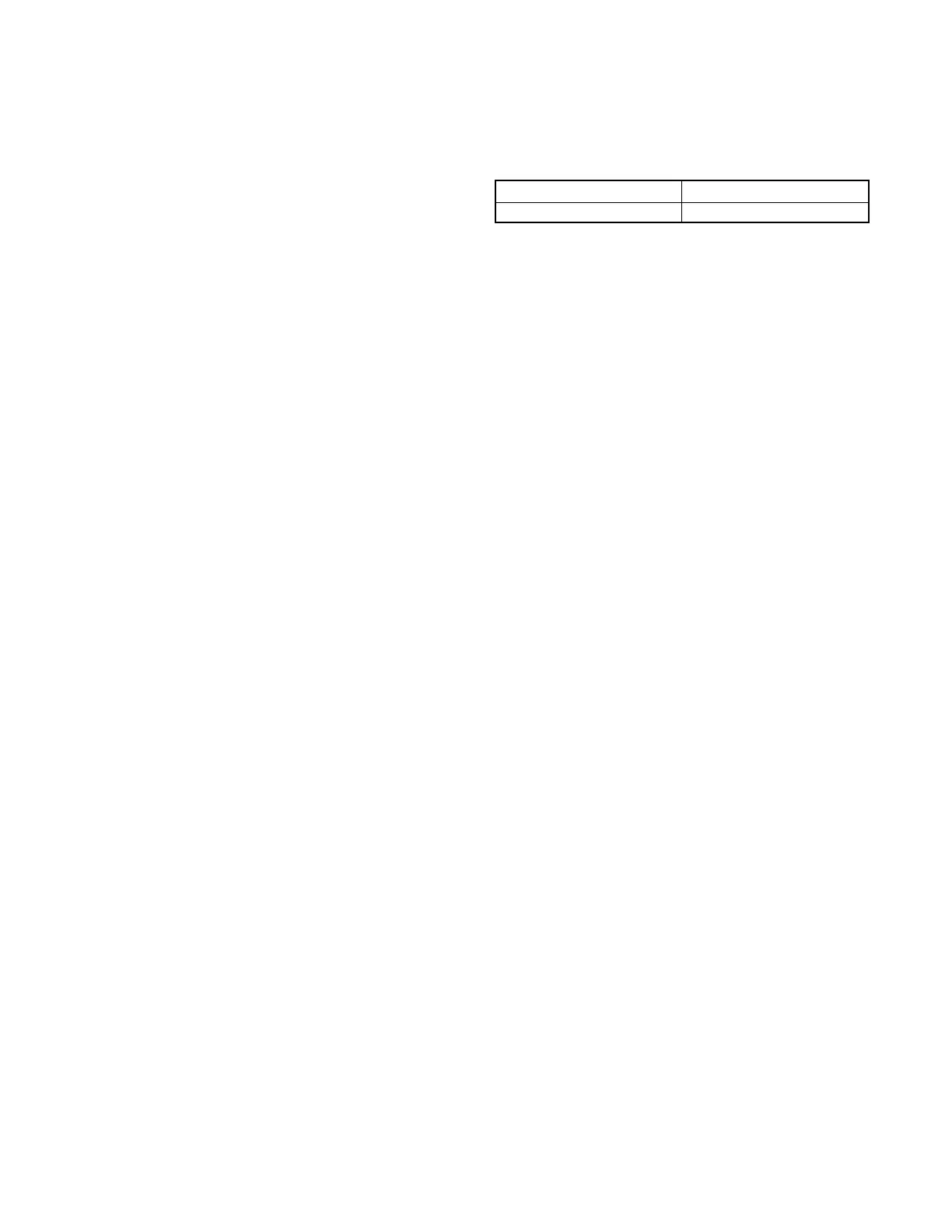

Dropout Voltage (VAC) Pickup Voltage (VAC)

160 190

Figure 4-10 Single-Phase Normal Source

Undervoltage Specifications

Use the following procedures to test normal source

sensing operation and calibration.

Normal Source Single-Phase Sensing Test

Follow the next steps to check single-phase sensing of

the normal source on both single- and three-phase

switches.

1. Disconnect the normal and emergency power

sources and the load from the transfer switch.

2. Connect a variable voltage source that ranges from

about 5% below the dropout specification to about

5% above the pickup specification to lugs NA-NC

on the contactor assembly. Increase the voltage

until the NA LED lights or the voltage is 5% above

the pickup voltage specification in Figure 4-10

3. If the NA LED does not light, replace the controller

assembly.

4. If the NA LED lights, reduce the voltage until the NA

LED turns off or is 5% below the dropout voltage

specification. If the NA LED remains lit, replace the

controller assembly. If the LED turns off, check the

voltage. If the voltage is not within ±5% of the

dropout voltage specification, replace the

controller assembly.

5. Increase the voltage until the NA LED lights. If the

voltage is not within ±5% of the pickup

specification, replace the controller assembly.

Loading...

Loading...