NOTE: Before proceeding with any operation on the engine,

stop it and allow it to cool.

Warning

• Presence of steam pressurized coolant danger of burns.

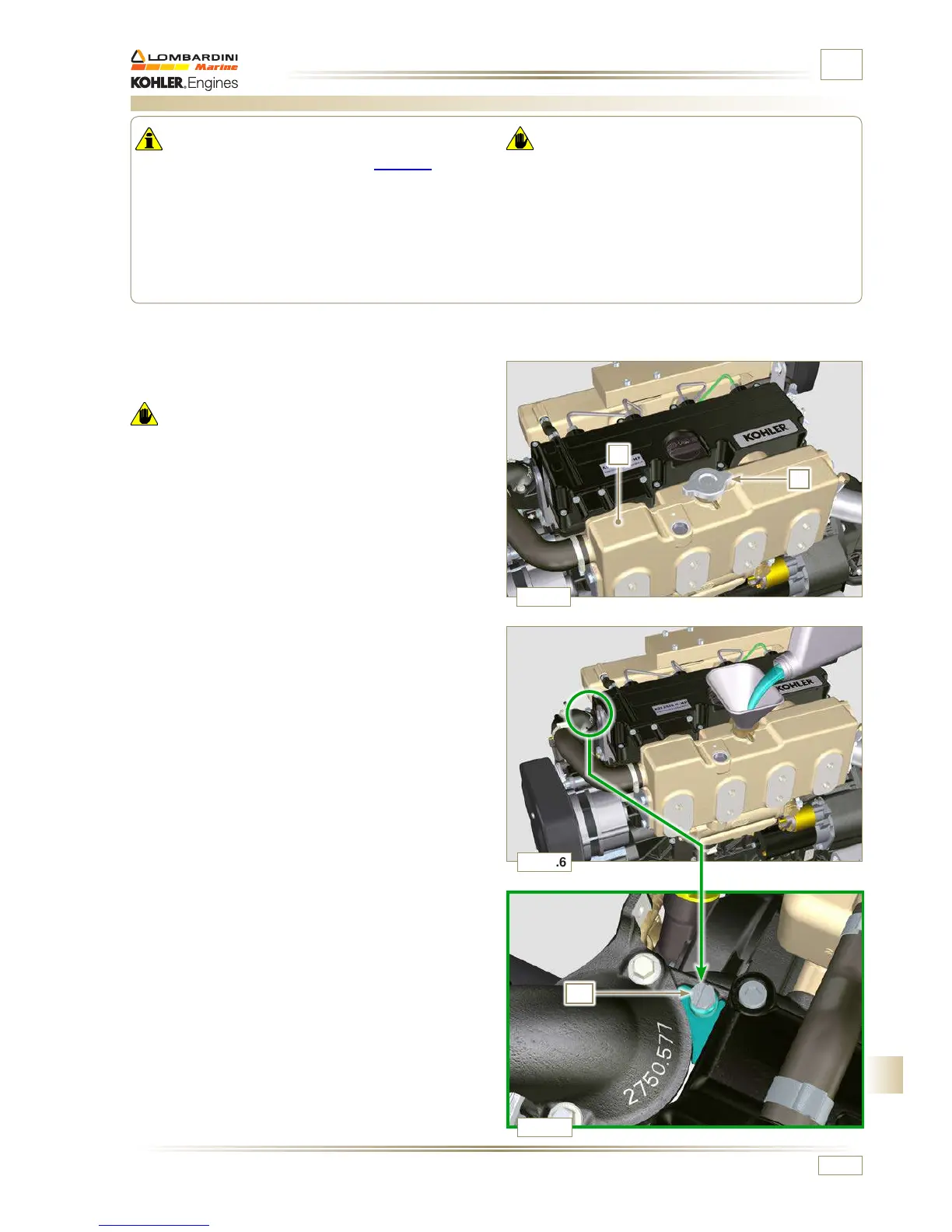

1 - Loosen the cap A and fill the cooled exhaust manifold B

with coolant composed of:

50% ANTIFREEZE and 50% decalcified water.

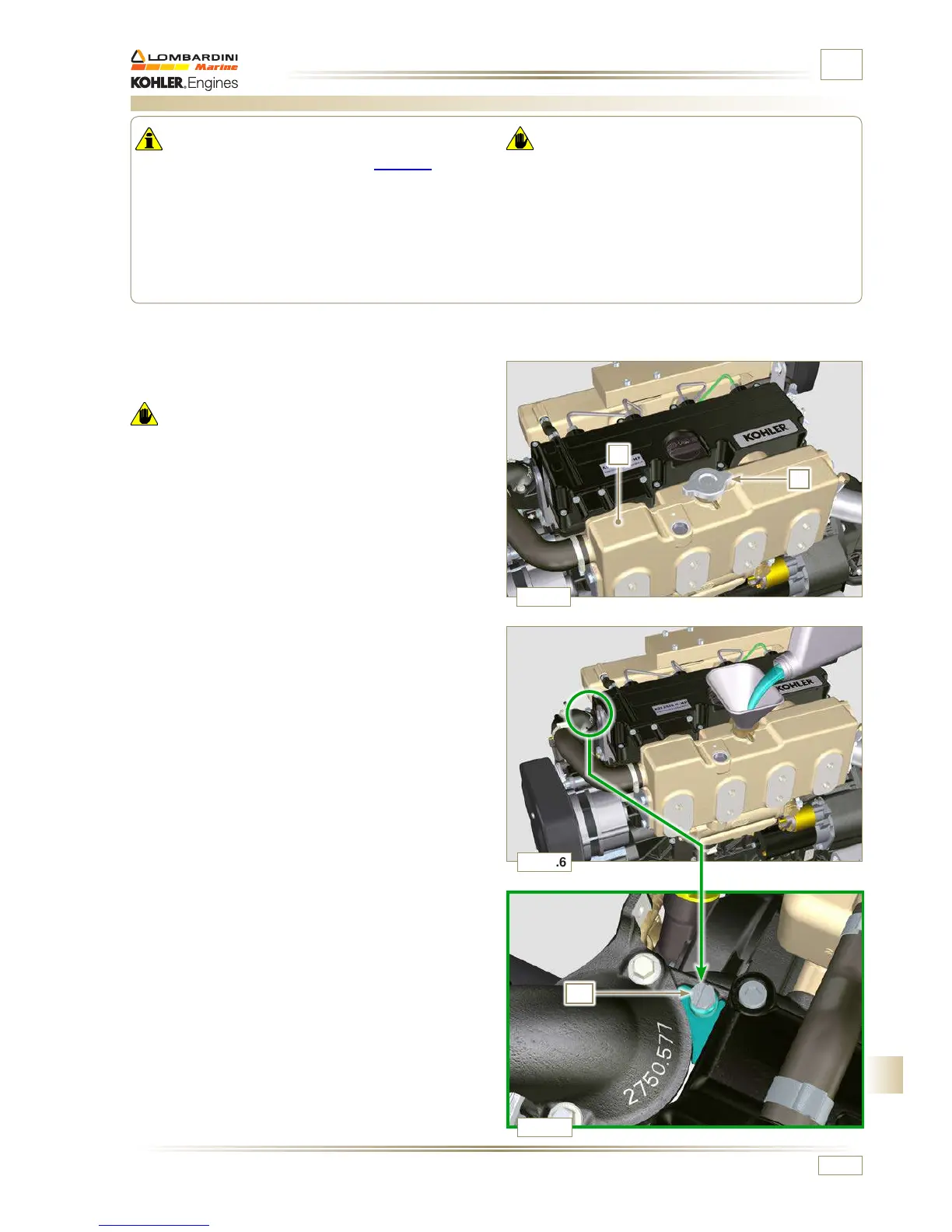

2 - Loosen the screw C release any air and tighten the screw

C (Tightening torque of 8 Nm - Fig. 4.7).

NOTE: The MAX lling level for exhaust manifold B is in

correspondence of capscrew C, complete the coolant

relling procedure as soon as the coolant starts leaking

out of capscrew C (Fig. 4.7).

3 - Re-tighten the cap A.

4 - After a few minutes of operator, stop the engine and allow

the liquid to cool returns to a ambient temperature and

check the coolant level again.

4.7 Coolant lling

Important

• Before proceeding with operation, read Par. 3.2.2.

• Place engine on horizontal surface to ensure accurate

measurement of filling.

Warning

• An anti-freeze protection liquid (ANTIFREEZE) - mixed with

decalcified water - must be used.

• The freezing point of the refrigerant mixture depends on the

amount concentration in water.

• As well as lowering the freezing point, the antifreeze also

raises the boiling point.

• A 50% mixture is recommended to ensure a general level at

protection prevents the formation of rust, galvanic currents

and calcium deposits.

Loading...

Loading...