CPK

1. General

Your centrifugal pumps will give you completely trouble free

and satisfactory service on condition that it is installed with

due care and properly maintained. It is absolutely essential

that the instructions contained in this manual be scrupulously

observed and that the pumps are not operated under conditions

which differ from those specified under our ‘Operating

Conditions’. This operating instruction manual does not take

any account of any safety regulation which may apply to the

installation site, and the Site Engineer or Site Operator is

responsible for notifying our erection staff of any such

regulations and seeing that they are complied with.

The pump type size, main operating data and works order

number are stamped on the name plate affixed to the pump.

Please make sure to quote this information every time you

write to us in respect of queries, repeat orders and particularly

when ordering spare parts.

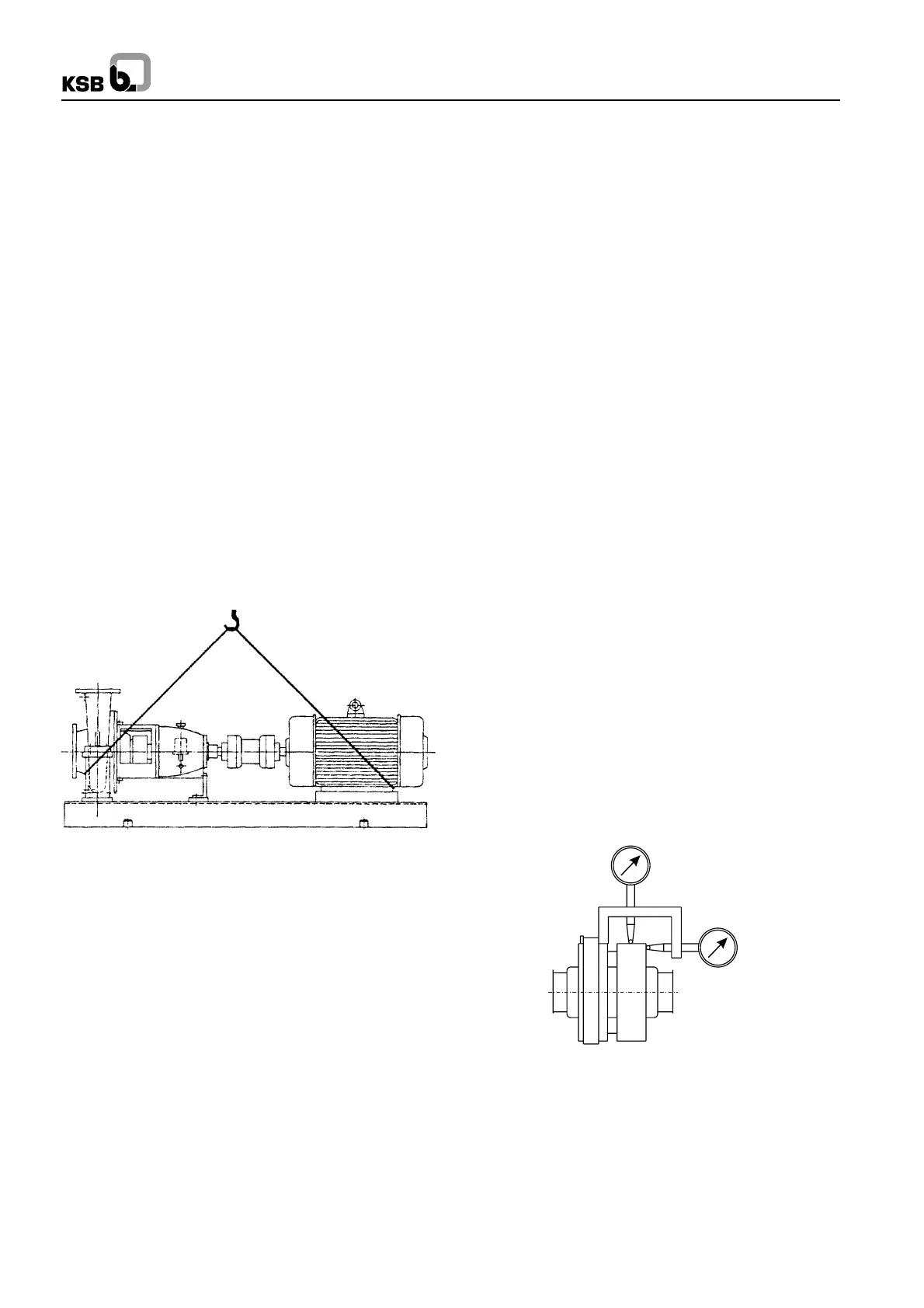

1.1 Handling

The Pump set should be properly handled and slung for

transport. Do not thread the ropes through the eye bolt on the

motor. (See Fig. 1)

During handling do not remove the rubber blankings provided

on the suction and discharge nozzles.

2. Installation (on site)

2.1 Foundation

Make sure that the concrete foundation has set firmly before

placing the base frame along with the pump set or pump on

it. The surface of the foundation should be truly horizontal and

perfectly flat. The foundation bolts should be suspended in

the baseplate.

2.2 Base Frame and Pump

Procedure

1. Bolt the Pump on the base frame.

2. Bolt the packer plates on the bottom pads of the base

frame, if applicable.

3. Place the unit on the foundation.

4. Suspend the foundation bolts in the pockets provided on

the foundation block.

5. Level the pump on the delivery flanges or feet within 0.2

mm per mtr., using jacking bolts provided on the corners

of the base frame.

Fig. 1 : Pump and driver mounted on a combined baseplate

2.4 Connecting the piping

Never use the pump itself as an anchor point for the piping.

Suction lift lines should be laid with a rising slope towards the

pump and suction head line with a downward slope towards

the pump. The pipelines should be anchored in close proximity

to the pump and should be connected to the latter without

transmitting any stress or strain, nor should the weight of the

piping be loaded on to the pump. The nominal sizes of the

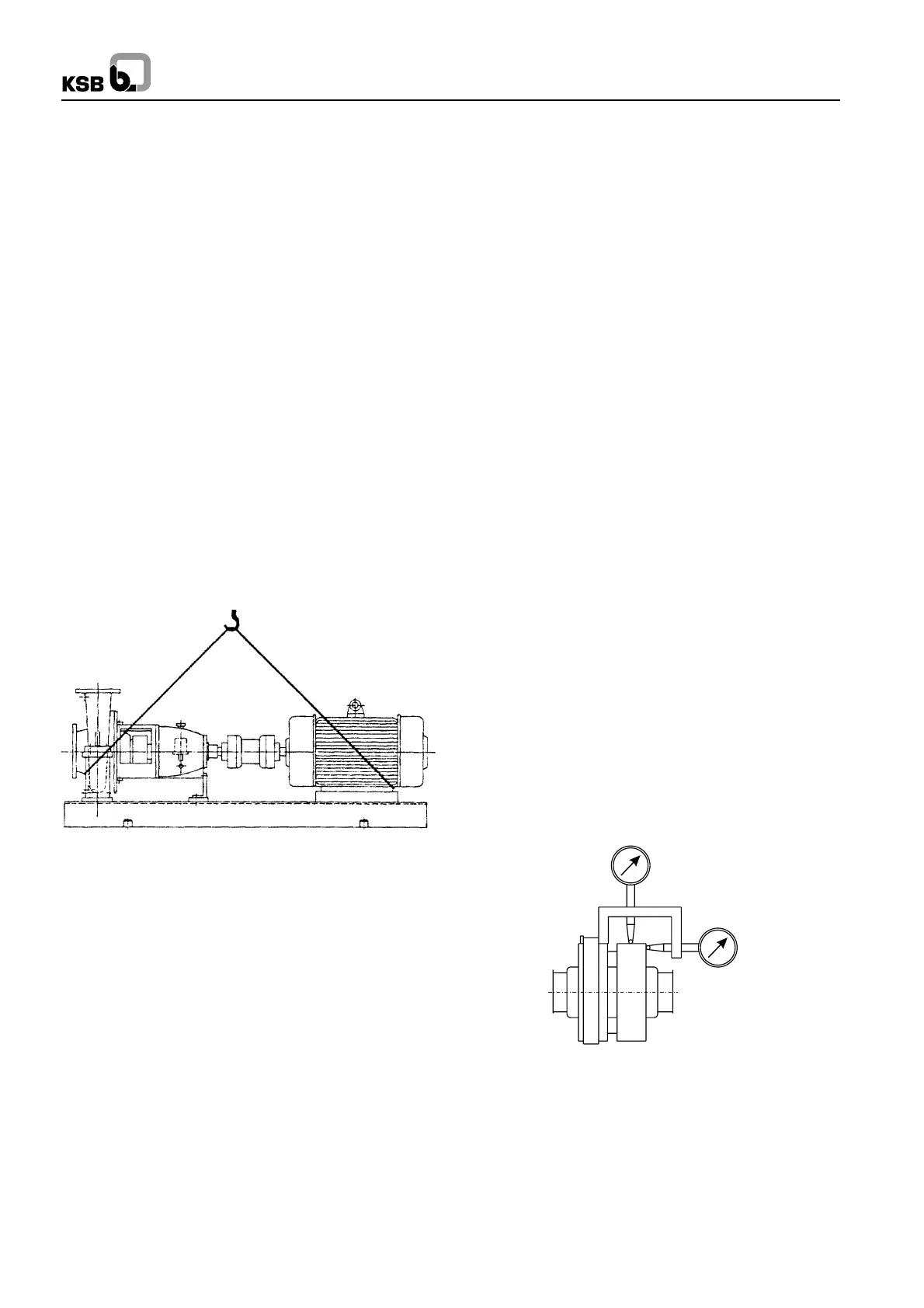

Fig. 2 : Alignment of coupling

6. Grout the foundation bolts and the packer plate (if

applicable) by using quick setting non-shrink cement,

ACC make “Shrinkkomp” or FORSORC make

“Conbextra-GP2” or equivalent.

7. Allow curing time of 24 to 72 hours depending upon the

grout used.

8. Remove bolts which are holding packer plates with the

base frame (if applicable).

9. Carry out final levelling by inserting shims (S.S. Shims

preferred) between packer plates and base frame (if

applicable).

10. Tighten the foundation bolts and recheck the levelling.

Correct it, if necessary.

11. Grout the complete base frame, including hollow portion,

if any, using conventional grouting mix i.e. portland

cement, sand and aggregate in proportion 1:2:4 and

gravel size not exceeding 20 mm.

12. Plaster the foundation and apply suitable oil resistant

paint.

For figures refer Annexure I.

2.3 Alignment of pump and driver

Accurate coupling alignment requires a coupling alignment

jig. This can be manufactured from 20 x 20 mm steel flat. The

jig should be attached to the shafts. See Fig. 2.

The coupling can be considered correctly aligned with the aid

of the jigs illustrated if the difference measured does not

exceed 0.1 mm both in the radial and axial directions,

measurements being taken in 4 planes at 90

0

intervals.

Alignment should be checked when the pump is hot

(applicable for pump handling hot fluids), In case any deviation

is found, please check the pipe lines and or realign the pump.

The coupling alignment check should be repeated after the

piping has been connected to the pump to ensure stress free

piping. Prior to alignment, individual concentricity of coupling

should be checked. It should be within 0.03 mm. If not,

corrective action should be taken. The coupling should be

dynamically balanced in accordance with VDI 2060 (ISO

1940)/G6.3 for motor driven pumps and G2.5 for turbine driven

pumps.

1

Loading...

Loading...