5 Installation at Site

27 of 80

HPK

1121.8/06-EN

CAUTION

Aggressive flushing liquid and pickling agent

Damage to the pump!

▷ Match the cleaning operation mode and duration of flushing and pickling to

the casing materials and seal materials used.

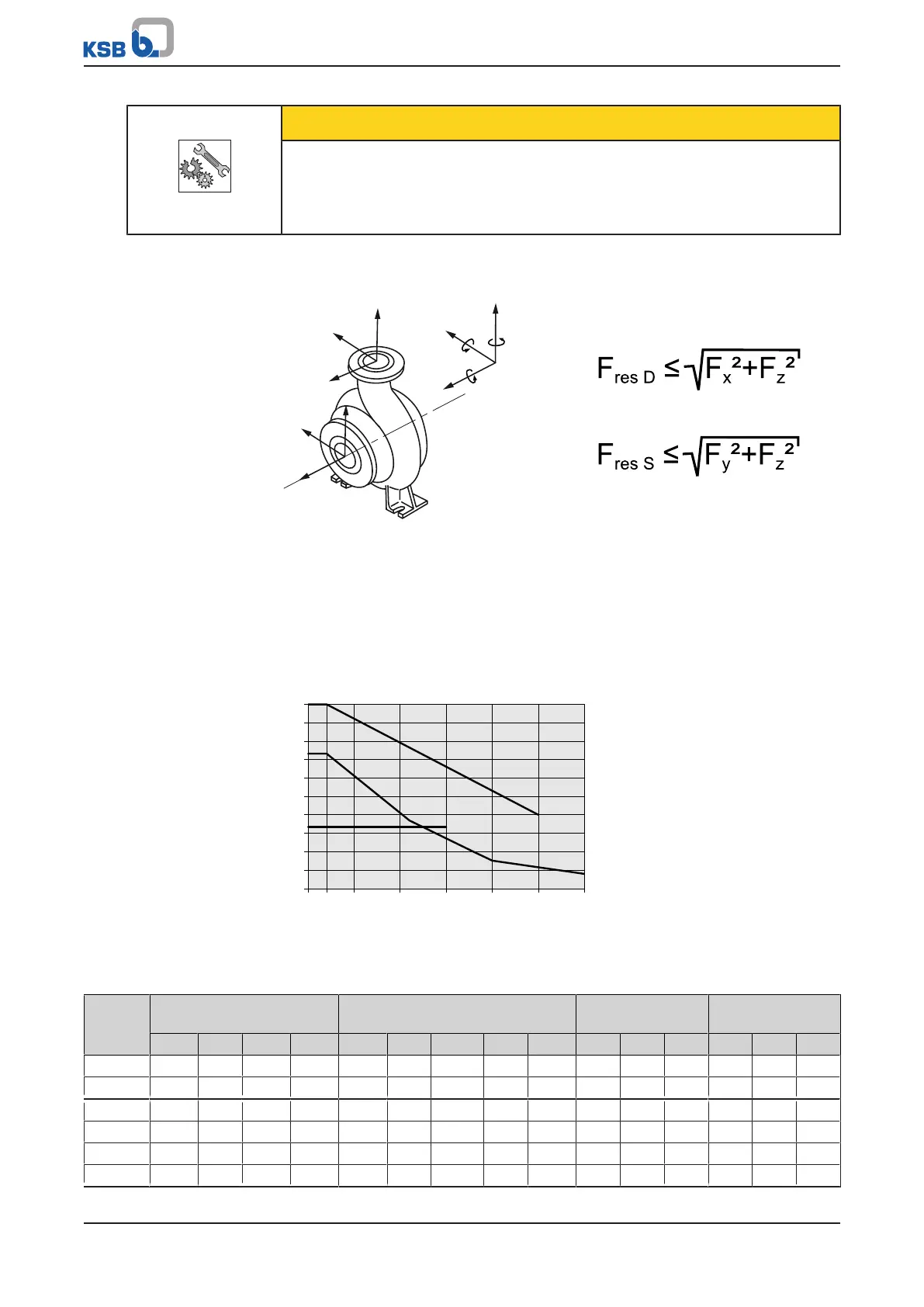

5.4.2 Permissible forces and moments at the pump nozzles

[+]

F

y

F

z

F

x

F

x

F

z

F

y

F

x

F

z

F

y

M

y

M

z

M

x

Forces and moments at the pump nozzles

The permissible resultant forces have

been determined according to:

The data on forces and moments apply to static piping loads only. If the limits are

exceeded, they must be checked and verified.

If a computerised strength analysis is required, values are available on request only.

The values are only applicable if the pump is installed on a completely grouted

baseplate and bolted to a rigid and level foundation.

No reduction is necessary for material 1.7706.

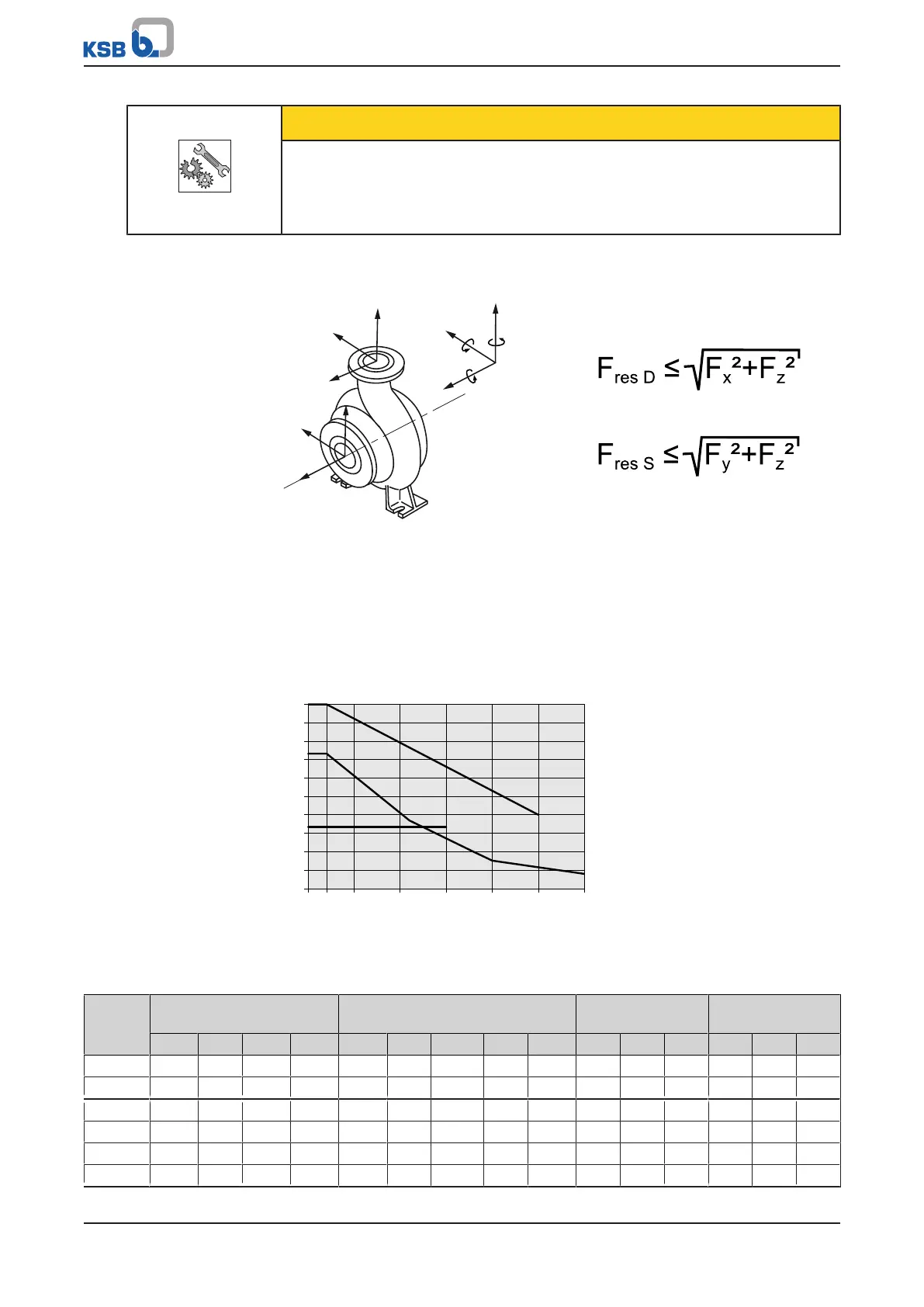

1,00

0,75

0,80

0,85

0,90

0,95

0,50

0,55

0,60

0,65

0,70

400350300250200150120

JL1040

GP240GH+N

JS1025

1.4408

°C

Correction coefficient

Fig.10: Temperature correction diagram

Pump model HPK-E/EX/E4/S/SX

Table11: Forces and moments at the pump nozzles

Sizes

Suction nozzle

[N]

Discharge nozzle

[N]

Suction nozzle

[Nm]

Discharge nozzle

[Nm]

F

x

F

y

F

z

F

res

F

x

F

yTens

+ F

yCompr

- F

z

F

res

M

x

M

y

M

z

M

x

M

y

M

z

25-160 1050 700 850 1100 500 350 650 450 700 550 450 300 400 300 200

25-200 1050 700 850 1100 500 350 650 450 700 550 450 300 400 300 200

32-125 1350 900 1100 1400 700 450 850 550 900 700 550 350 450 350 250

32-160 1350 900 1100 1400 700 450 850 550 900 700 550 350 450 350 250

32-200 1350 900 1100 1400 700 450 850 550 900 700 550 350 450 350 250

32-250 1350 900 1100 1400 700 450 850 550 900 700 550 350 450 350 250

Loading...

Loading...