7 Servicing/Maintenance

65 of 80

HPK

1121.8/06-EN

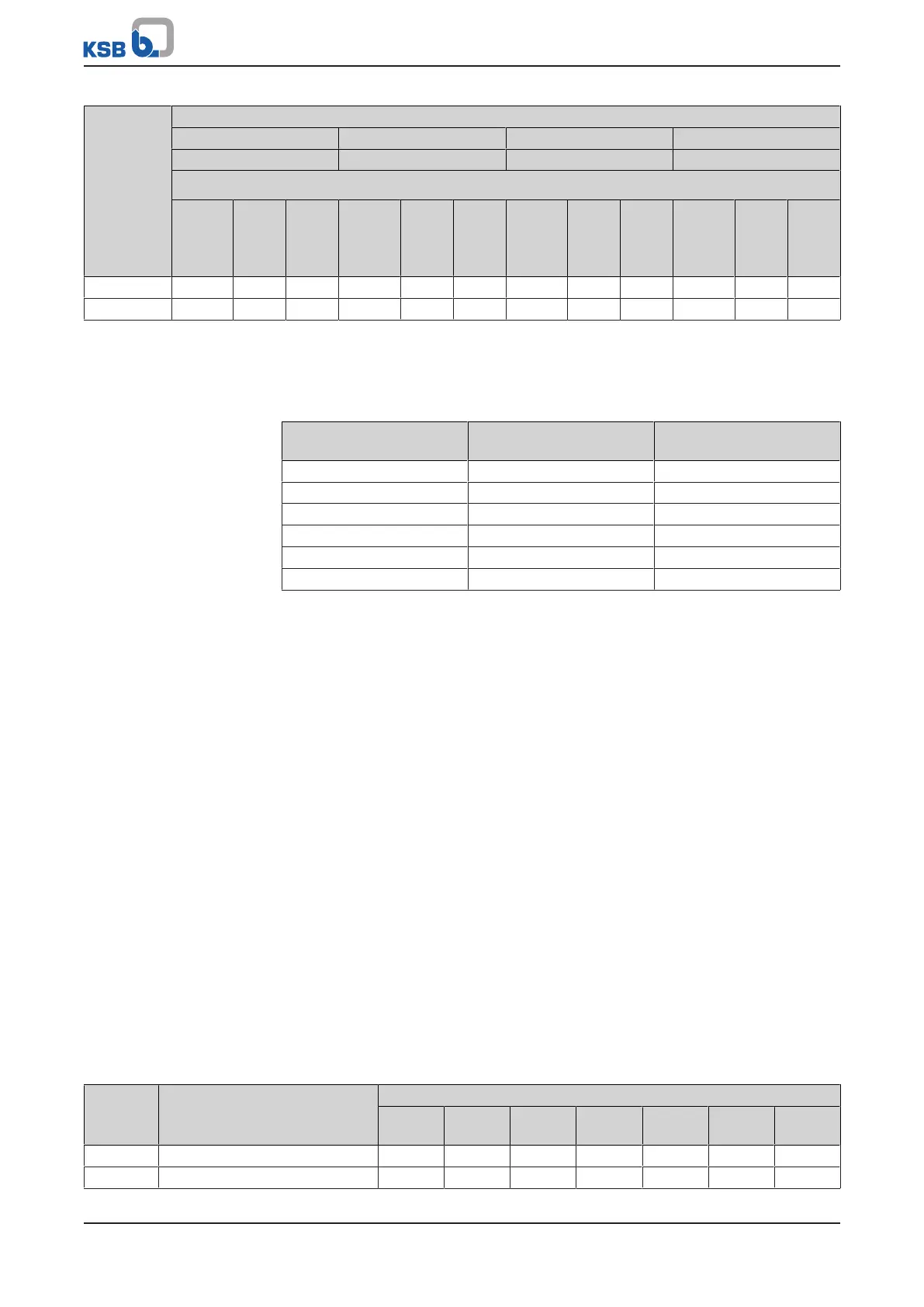

Thread Material of stud/hexagon nut

C35E+Qt/C 35 A4-70/A4-70 1.7709+QT/1.7258+QT 1.6772/1.6722

YK/Y A4-70/A4-70 GA/G MM/MM (M3k)

Stamp mark on stud/hexagon nut

13)

Brand-new

threads

14)

-15 %

15)

-20 %

15)

Brand-new

threads

14)

-15 %

15)

-20 %

15)

Brand-new

threads

14)

-15 %

15)

-20 %

15)

Brand-new

threads

14)

-15 %

15)

-20 %

15)

M16 100 85 80 155 131,7 124 190 161,5 152 320 272,0 256

M20 - - - 200 170 160 330 280,5 264 620 572,0 496

7.6.2 Tightening torques for the impeller nut

Observe the following tightening torques for impeller nut (922):

Table28: Tightening torques for the impeller nut

Bearing bracket Tightening torques

[Nm]

Width across flats

[mm]

P02as 55 22

P03s, P03as 125 27

P04s, P04as 200 32

P05s, P05as 300 41

P06s, P06as 520 55

P08s 1000 60

Re-tighten the impeller nut some 20 to 30 minutes after assembly.

7.7 Spare parts stock

7.7.1 Ordering spare parts

Always quote the following data when ordering replacement or spare parts:

▪ Order number

▪ Order item number

▪ Type series

▪ Size

▪ Material variant

▪ Year of construction

Refer to the name plate for all data.

Also specify the following data:

▪ Part number and description

▪ Quantity of spare parts

▪ Shipping address

▪ Mode of dispatch (freight, mail, express freight, air freight)

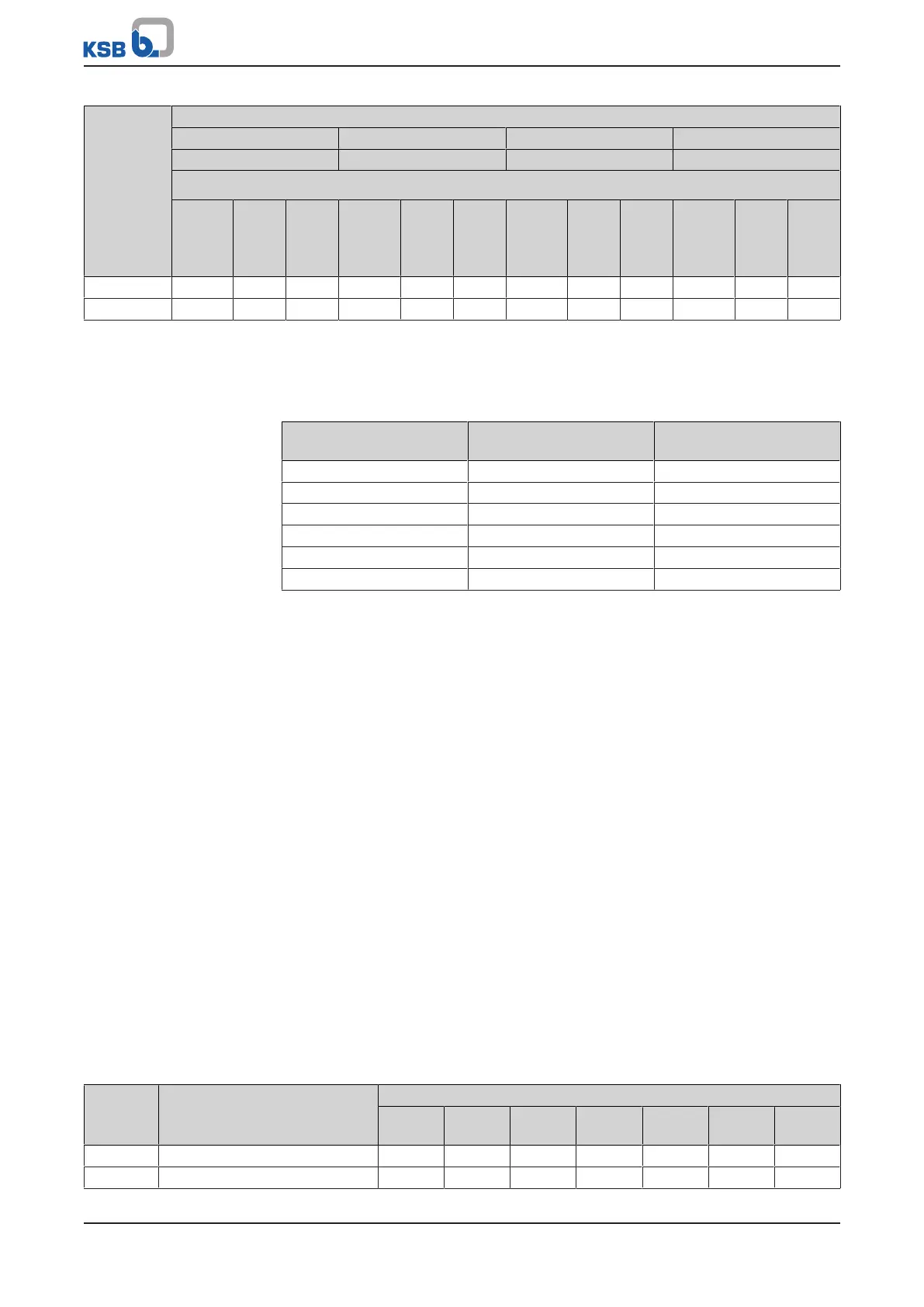

7.7.2 Recommended spare parts stock for 2 years' operation to DIN24296

Table29: Quantity of spare parts for recommended spare parts stock

Part No. Description Number of pumps (including stand-by pumps)

2 3 4 5 6 and 7 8 and 9 10 and

more

210 Shaft 1 1 1 2 2 2 20 %

230 Impeller 1 1 1 2 2 2 20 %

Loading...

Loading...