5 Description

12 of 44

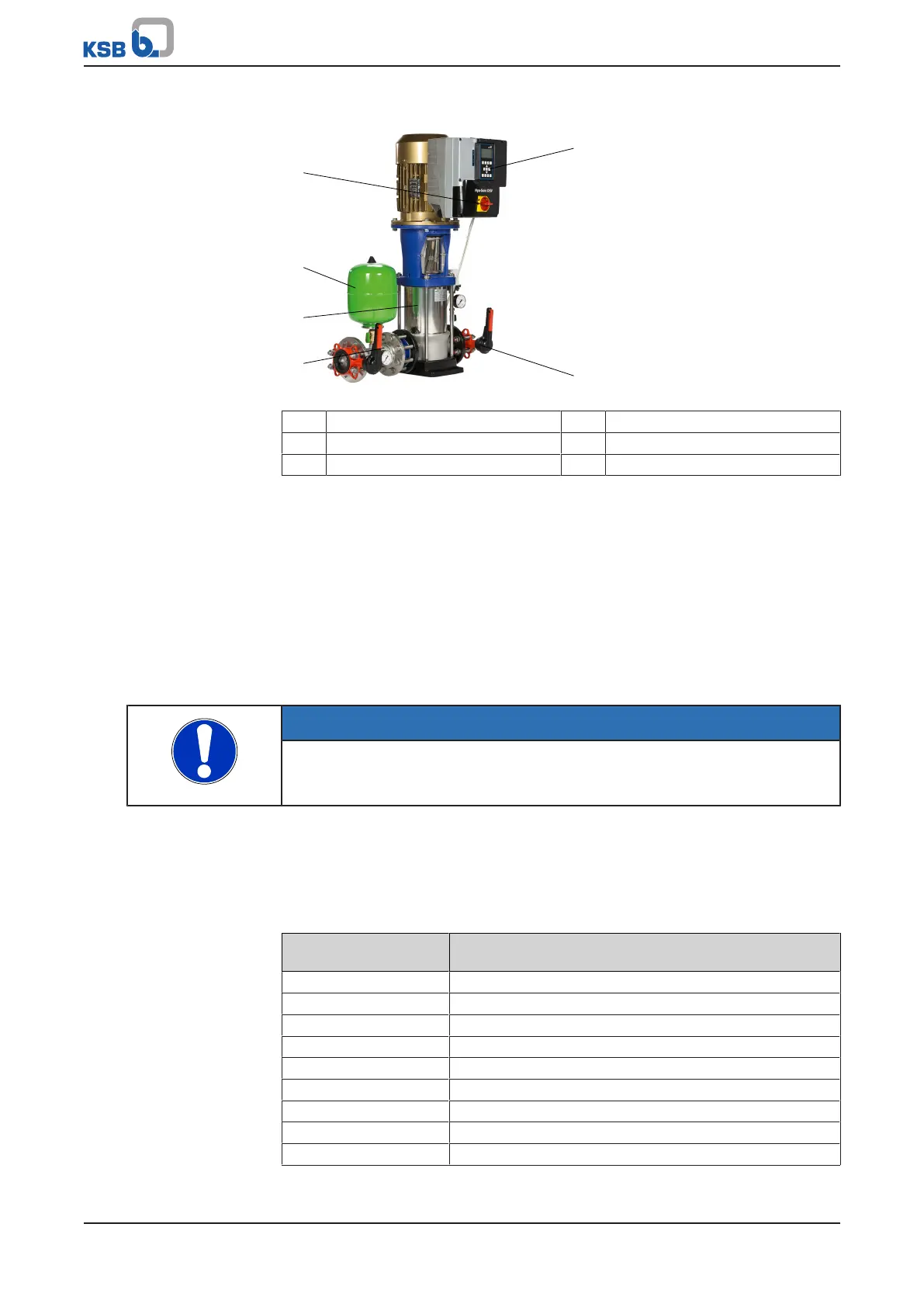

Hya-Solo DSV

5.5 Configuration and function

Fig.3: Illustration of a Hya-Solo DSV

1 Master switch 2 Accumulator

3 Pump 4 Pressure sensor

5 PumpDrive 6 Valves

Design

The fully automatic pressure booster system is equipped with a non-self-priming

vertical high-pressure pump (3) for pumping the fluid handled to the consumer

installations at a constant pressure.

Function

Automatic mode

The pump is started as a function of pressure and stopped as a function of flow by a

fully automatic control unit. If the pressure drops below the pre-set pressure, the

pump starts up and the frequency inverter controls the pressure booster system to

maintain the set pressure, so that the pressure is kept constant.

If the demand decreases, the pump stops as soon as the flow rate has fallen below a

set minimum value.

Function

Manual mode

A key for manual operation is provided on the control panel. In manual mode the

pump operates at the pre-set minimum speed, independently of the automatic

system (pressure transmitter) or an External ON/OFF signal.

NOTE

Continuous manual mode is reserved exclusively for emergencies!

Continuous operation of the pressure booster system in manual mode may result in

waste of energy and water.

In manual mode, a minimum flow (see table below) is essential to prevent the fluid

handled and the pump from overheating when no water is consumed at the

consumer installations.

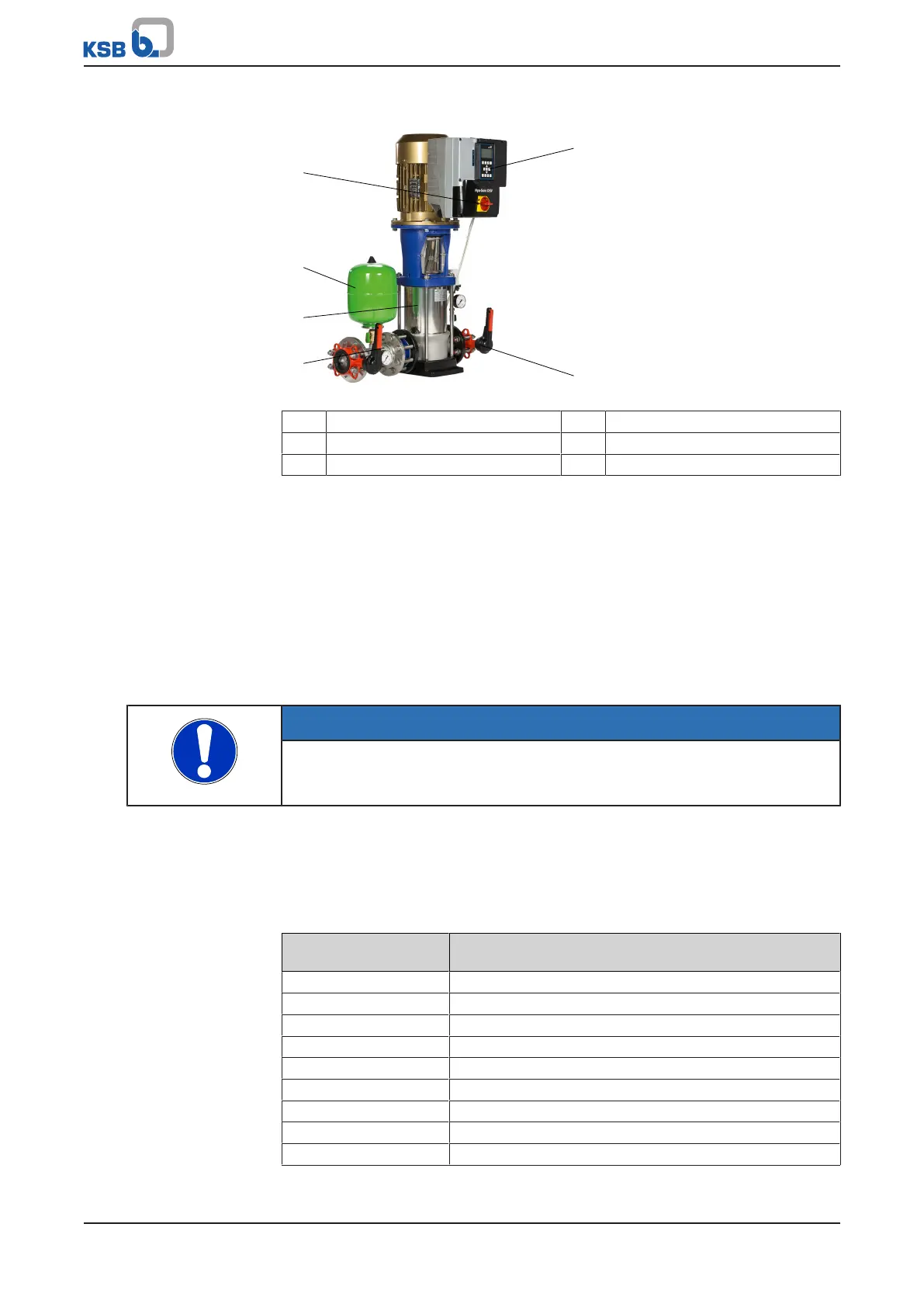

Minimum flow for pump in manual mode

Table5: Minimum flow per pump in manual mode

Pump Minimum flow per pump in manual mode

[l/h]

Movitec 2B 200

Movitec 4B 400

Movitec 6B 600

Movitec 10B 1100

Movitec 15B 1600

Movitec 25B 2800

Movitec 40B 4600

Movitec 60B 6100

Movitec 90B 8500

Example

An open

1

/

2

-inch tap equals a water consumption of approx. 800 to 1,200l/h.

Loading...

Loading...