6 Installation at Site

15 of 44

Hya-Solo DSV

NOTE

In order to avoid transmission of piping forces onto the pressure booster system

and transmission of solid-borne noise, we recommend installing length-limited

expansion joints.

Allow sufficient space for maintenance and repair work.

ü All structural work required has been checked.

ü The dimensions of the concrete foundation are correct, and the concrete has set

firmly.

1. Mark out the anchoring holes on the floor as shown in the outline drawing.

2. Drill the holes (max. diameter: 12mm).

3. Insert plug fixings of appropriate size.

4. Set the pressure booster system down in its correct installation position.

5. Use suitable bolts to firmly anchor the pressure booster system.

6.4 Installing the piping

Make sure that piping is installed without transmitting any stresses or strains. The use

of length-limited expansion joints (see accessories) is recommended.

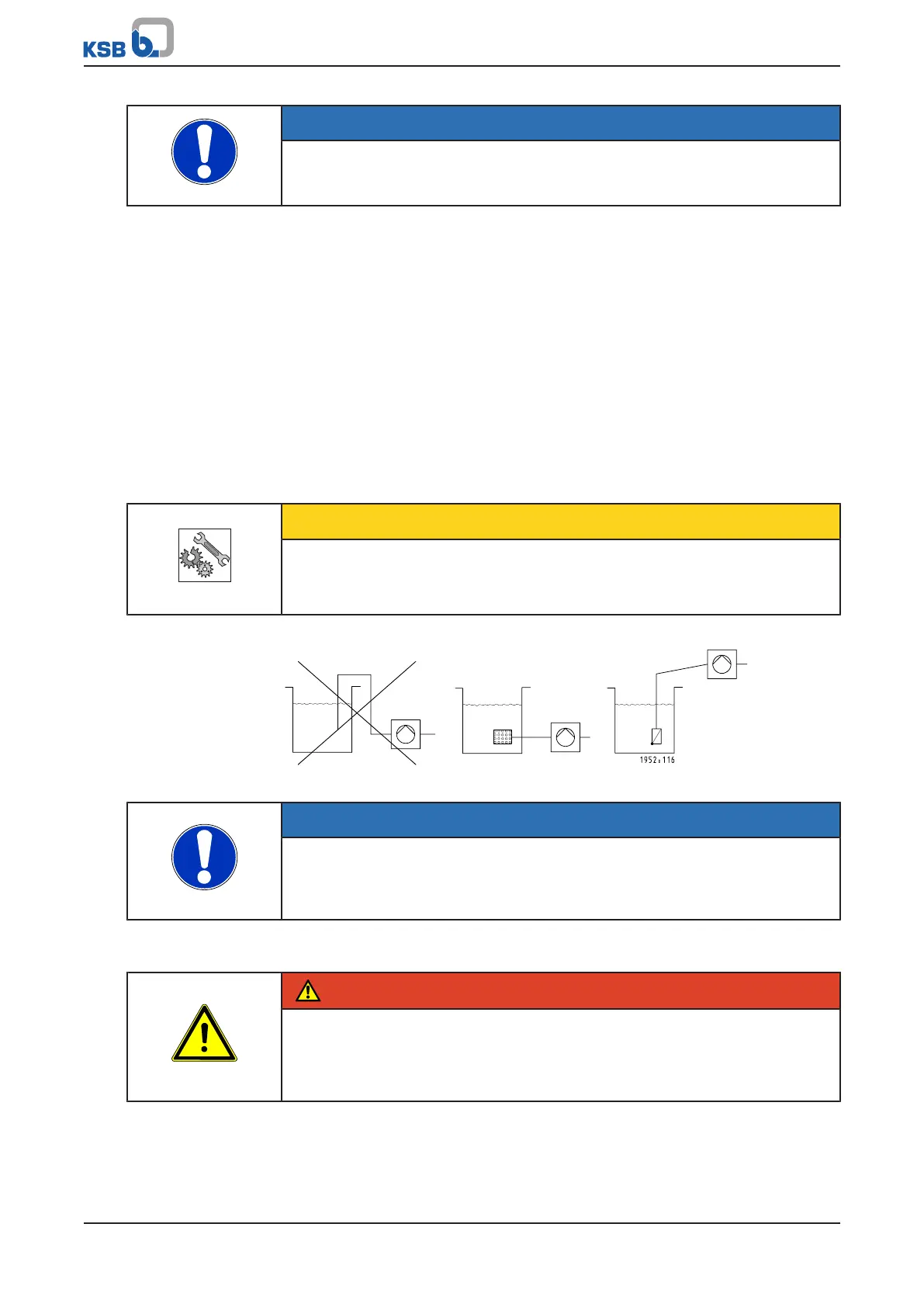

CAUTION

Air pockets in suction line

Pressure booster system cannot prime!

▷ Lay piping with a continuously rising slope (as shown).

Suction lift operation

Incorrect Correct

NOTE

For suction lift operation install suitable swing check valves at the suction line ends

which are submerged in the fluid handled. Take into account the head losses

caused by these swing check valves.

Do not exceed the maximum suction lift of the pumps.

6.4.1 Fitting an expansion joint

DANGER

Sparks and radiant heat

Fire hazard!

▷ Take suitable precautions to protect the expansion joint if any welding work is

carried out nearby.

Loading...

Loading...