10 Trouble-shooting

36 of 44

Hya-Solo DSV

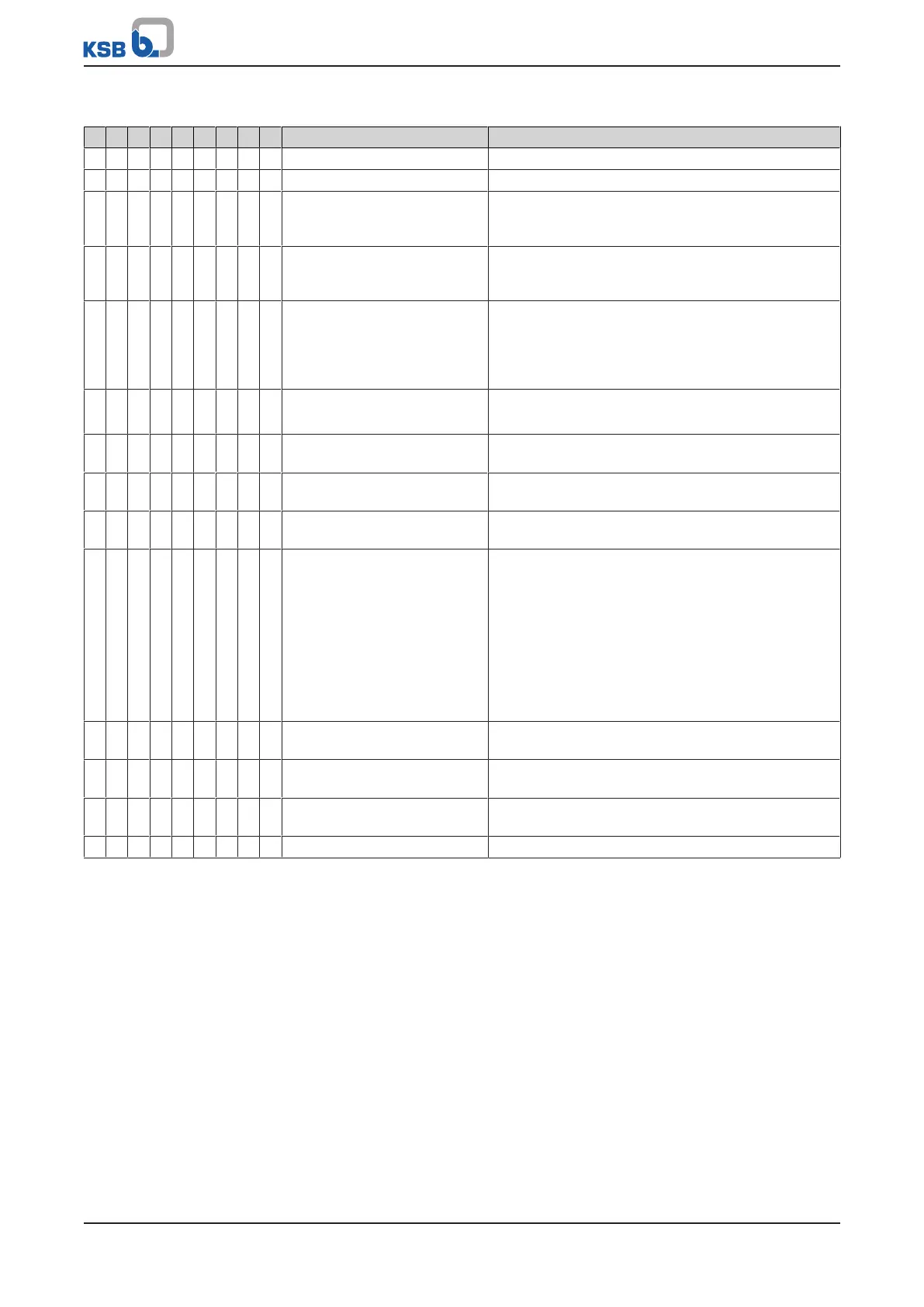

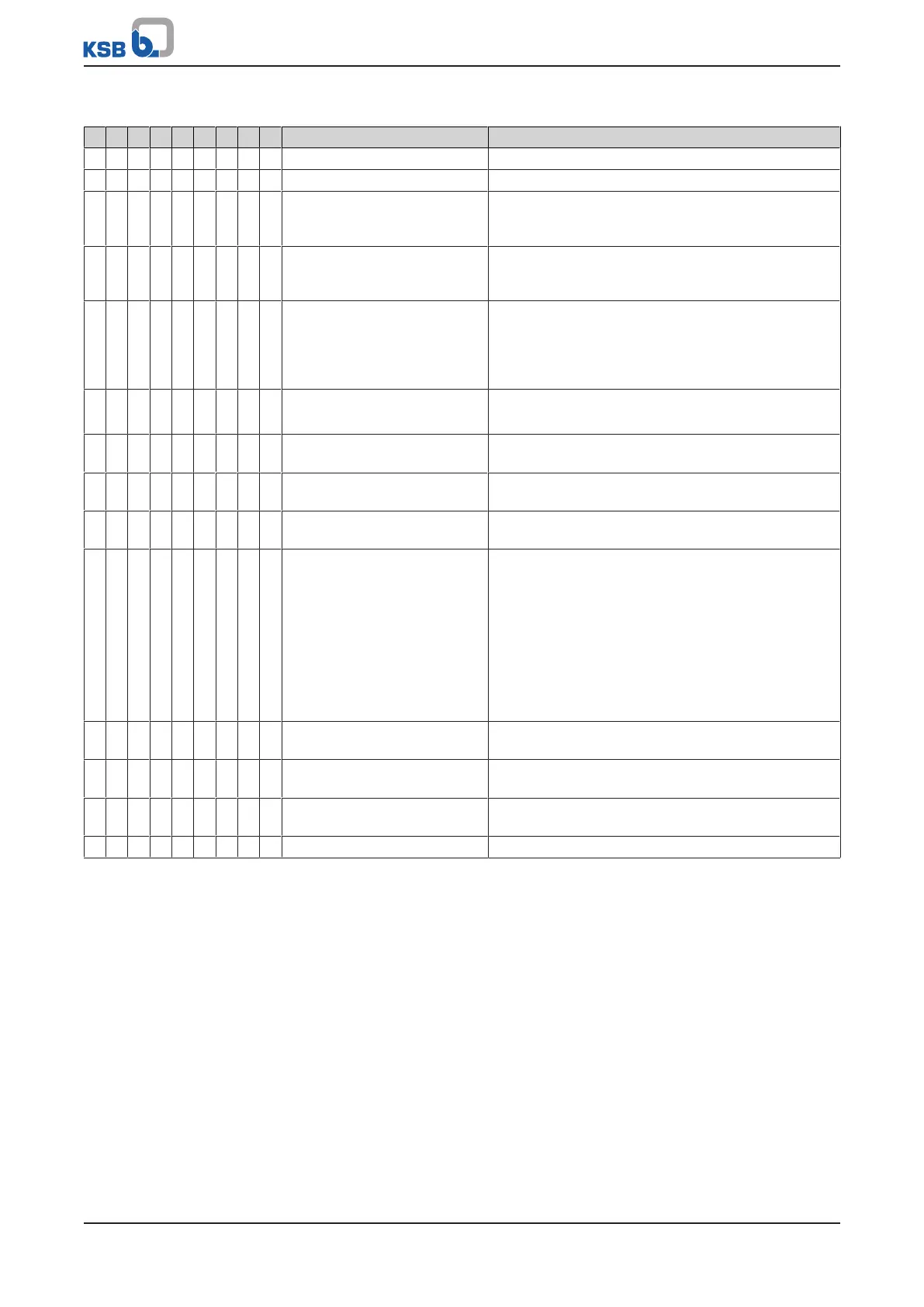

Table21: Trouble-shooting

A B C D E F G H I Possible cause Remedy

- ✘ - - - - ✘ - - No voltage Check the mains voltage; check the mains fuses.

- ✘ - - - - - - - No enable Check enable via DIGIN-EN and system start.

✘ - - - - - - - - Mains fuse rating too small for

frequency inverter input

current

Check design configuration of mains fuse.

- - - ✘ - - - - - No setpoint signal or setpoint

set too low / drive overloaded

and in i²t control mode

Check setpoint signal and operating point.

- - - - ✘ - - - - Process-related persistent

control deviation (actual value

smaller than setpoint) / no

actual value (e.g. due to

broken wire)

Check setpoint/actual value signal; check operating

point; check controller setting.

- ✘ -

-

- - - - - ✘ Permissible voltage range

undershot/exceeded

Check mains voltage; supply frequency inverter with

required voltage.

- - - - - - - ✘ - Wrong direction of rotation

setting

Change the direction of rotation.

- - ✘ ✘ - - - - ✘ Frequency inverter overloaded Reduce the power input by lowering the speed;

check the motor/pump for blockages.

- ✘ - - - - - - ✘ Short circuit in control cable/

pump blocked

Check/replace control cable connections. Remove the

blockage manually.

- - ✘ ✘ - - - - ✘ Temperature of power

electronics or motor winding

too high

Reduce the ambient temperature by improving

ventilation.

Improve cooling by cleaning the cooling fins.

Ensure the intake opening for the motor fans is not

blocked.

Ensure that the motor fans are working properly.

Reduce the power input by changing the operating

point (system-specific).

Check the permissible load and, if necessary, use

external cooling.

- - - - - - ✘ - ✘ 24 V supply overloaded Disconnect PumpDrive from the power supply and

eliminate the cause of the overload.

- - - - - - - - ✘ Dry running of pump Check the hydraulic system and rectify the fault on

PumpDrive.

- - - ✘ - ✘ - - ✘ Sensor signal error (e.g.

broken wire)

Check sensor and sensor cable.

- ✘ ✘ - - - - - ✘ Phase failure, drive side Check motor connection and motor winding.

Loading...

Loading...