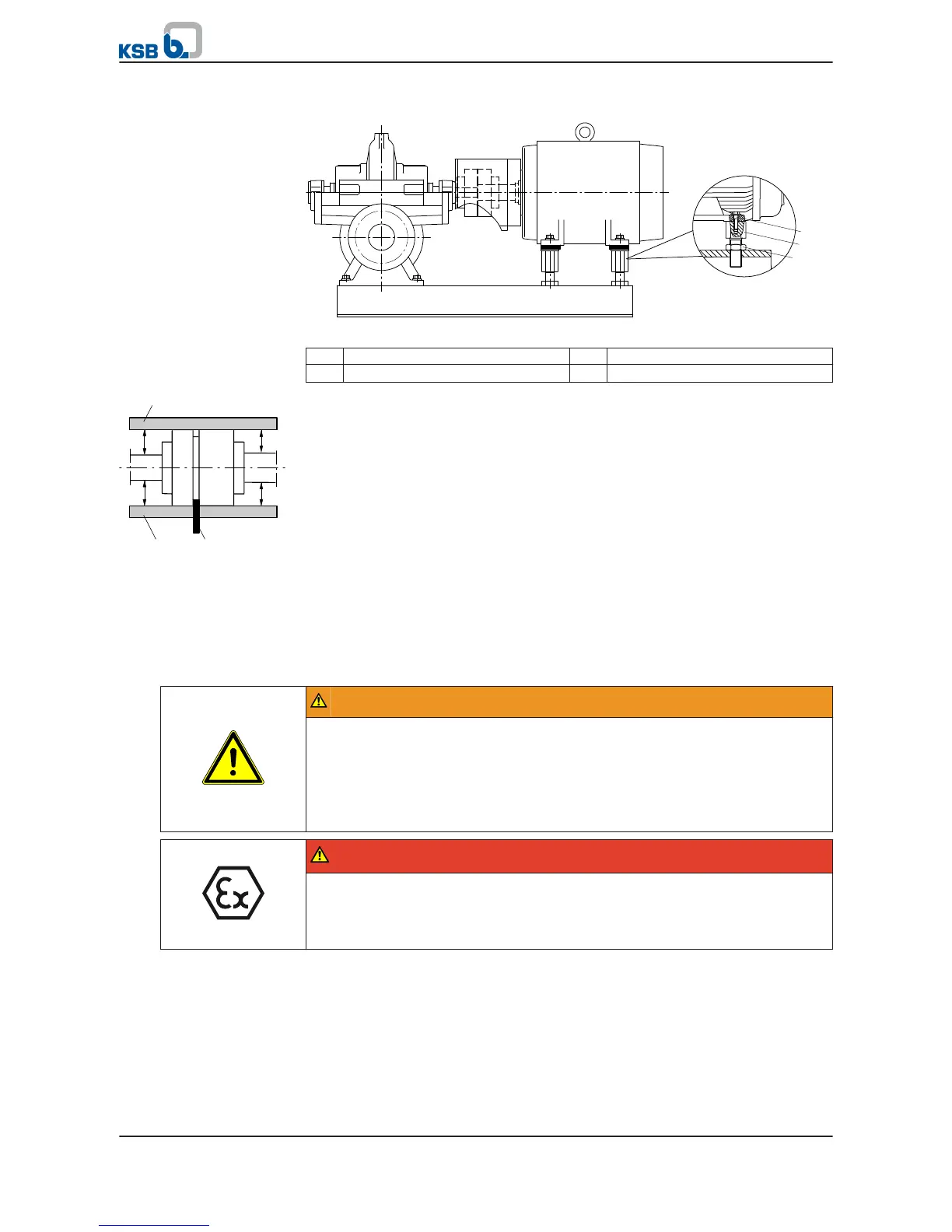

Fig. 14:

Aligning the motor with adjusting screws

1

Hexagon head bolt 2 Adjusting screw

3 Locknut

✓ The coupling guard and the footboard for the coupling guard, if any, have

been removed.

1. Place the straight-edge (c) axially on both coupling halves.

2. Leave the straight-edge (c) in this position and turn the coupling by hand.

⇨ The coupling is correctly aligned if the distances A and B to the respective

shafts are the same at all points around the circumference. The radial and

axial deviation of the two coupling halves must not exceed 0.05 mm. Observe

the coupling manufacturer's operating instructions!

3. Unscrew the hexagon head bolts (1) at the motor and the locknuts (3) at the

baseplate.

4. Turn the adjusting screws (2) by hand or by means of an open-end wrench until

the coupling alignment is correct and all motor feet rest squarely on the

baseplate.

5. Re-tighten the hexagon head bolts (1) at the motor and the locknuts (3) at the

baseplate.

6. Check that coupling/shaft can easily be rotated by hand.

WARNING

Unprotected rotating coupling

Risk of injury by rotating shafts!

▷ Always operate the pump set with a coupling guard.

If the customer specifically requests not to include a coupling guard in KSB's

delivery, then the operator must supply one!

▷ Observe all relevant regulations for selecting a coupling guard.

DANGER

Risk of ignition by frictional sparks

Explosion hazard!

▷ Choose a coupling guard material that is non-sparking in the event of

mechanical contact (see DIN EN 13463-1).

7. Re-install the coupling guard and the footboard for the coupling guard, if any.

8. Check the distance between coupling and coupling guard.

The coupling guard must not touch the coupling.

Loading...

Loading...