7. Fit the bearing cover.

8. Apply Loctite 5203 to the contact face of the lower casing section.

9. Tighten the bolts at the casing split flange diagonally, starting with the bolts

nearest the volute.

10. Insert the key for the coupling into pump shaft 211.

11. Install the coupling in accordance with the manufacturer's operating

instructions.

7.5.3 Mounting the pump set on the baseplate

Refer to the corresponding sections on how to install the pump set. (⇨ Section 5.3

Page 23)

✓ Suitably dimensioned lifting tackle is available.

✓ The corresponding general assembly drawing and/or installation instructions are

available.

✓ The pump has been completely assembled.

1. Use lifting equipment to lift up the pump, position it vertically and place it on

foot 182 (base frame).

2. Tighten screwed connection 901.12 between pump 655 and foot 182.

3. Use lifting equipment to lift drive lantern 341 and position it on the pump.

Align drive lantern 341 with locking sleeve 531.01. Tighten screwed connection

901.13 / 920.06 between pump and drive lantern.

4. For DK installation, fasten support foot 183 to drive lantern 341 with screwed

connection 901.60 and to foot 182 with screwed connection 901.61.

5. Proceed with the installation as described in the corresponding sections.

(⇨ Section 5.3.2 Page 25) , (⇨ Section 5.3.4 Page 27)

7.6 Tightening torques

With the exception of the following screwed/bolted connections, all screws/bolts

must be tightened as per the table "Tightening torques".

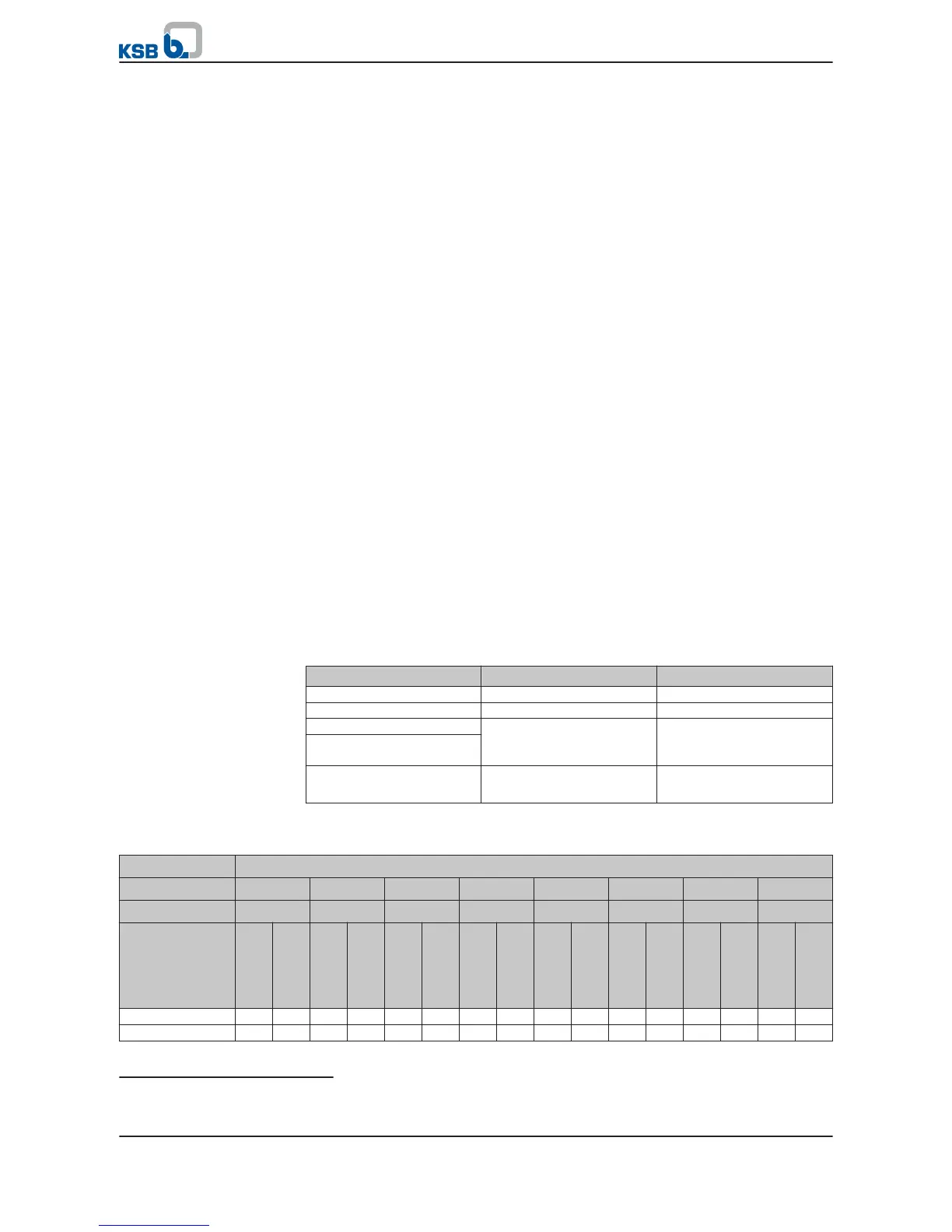

Part No. Description Tightening torque [Nm]

900.01 Foundation bolts (M16) 48

900.01 Foundation bolts (M20) 96

901.54 Motor screws/bolts Refer to the motor

manufacturer's product

literature.

901.14

920.2 Gland follower nuts (⇨ Section 6.1.4 Page 42)

Observe the following values:

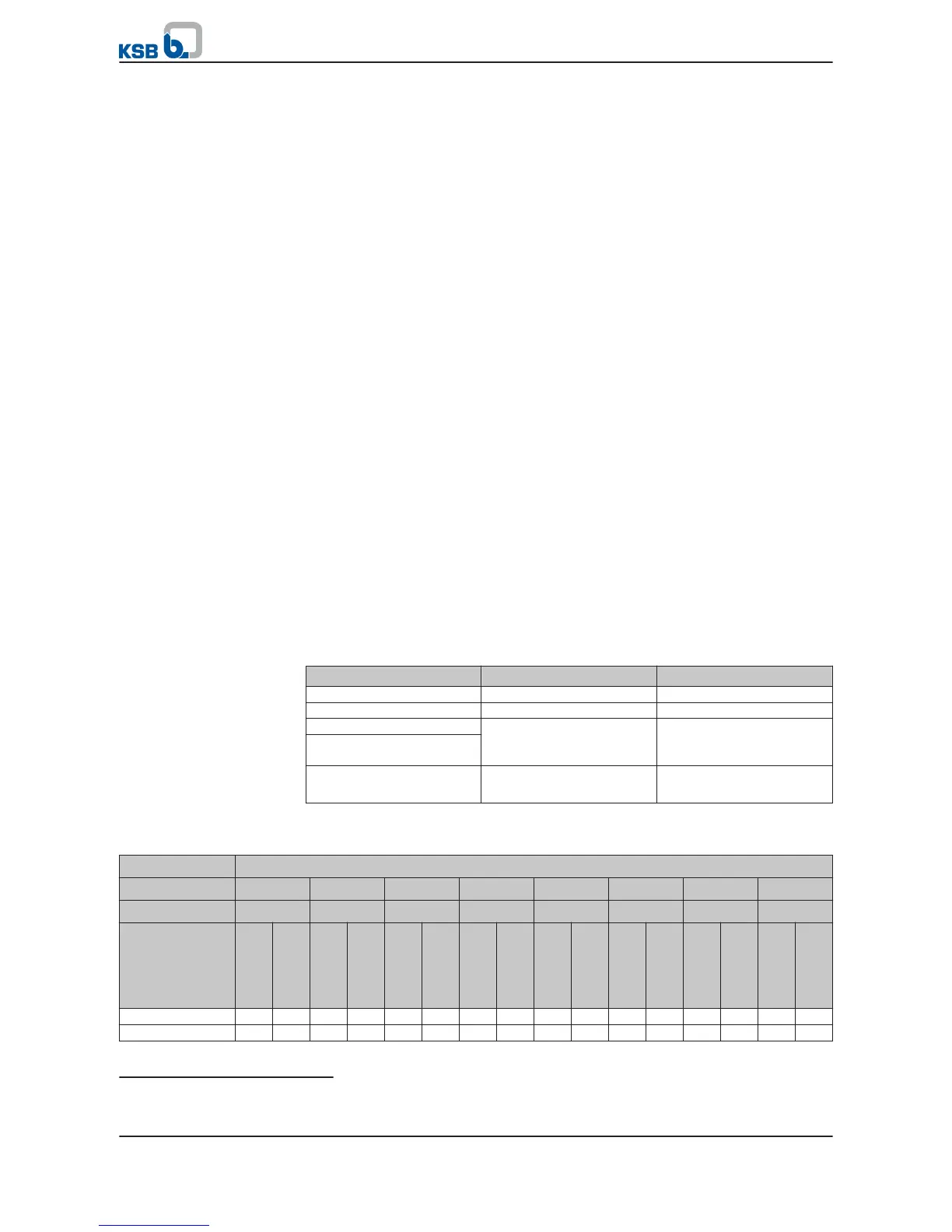

Table 18: Tightening torques

20)

Tightening torque M

A

[Nm]

Steel grade

A2, A4 A2, A4 A2, A4 C3 1.4410 1.4462

Property class 8.8 10.9 -50 -70 -80 -80

Thread

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

Minimum

Rated torque

M4 3,0 3,0 4,5 5,0 1,0 1,1 2,1 2,4 2,9 3,2 3,0 3,4 2,5 2,8 2,1 2,4

M5 6,1 6,8 9,0 9,9 2,0 2,2 4,3 4,8 5,7 6,3 6,1 6,8 5,0 5,6 4,3 4,8

Type of installation 3E

Type of installation DJ, DB

and DK

20)

For µTotal = 0.14 and 90 % of the minimum yield strength

7 Servicing/Maintenance

66 of 94

Omega / Omega V

Loading...

Loading...