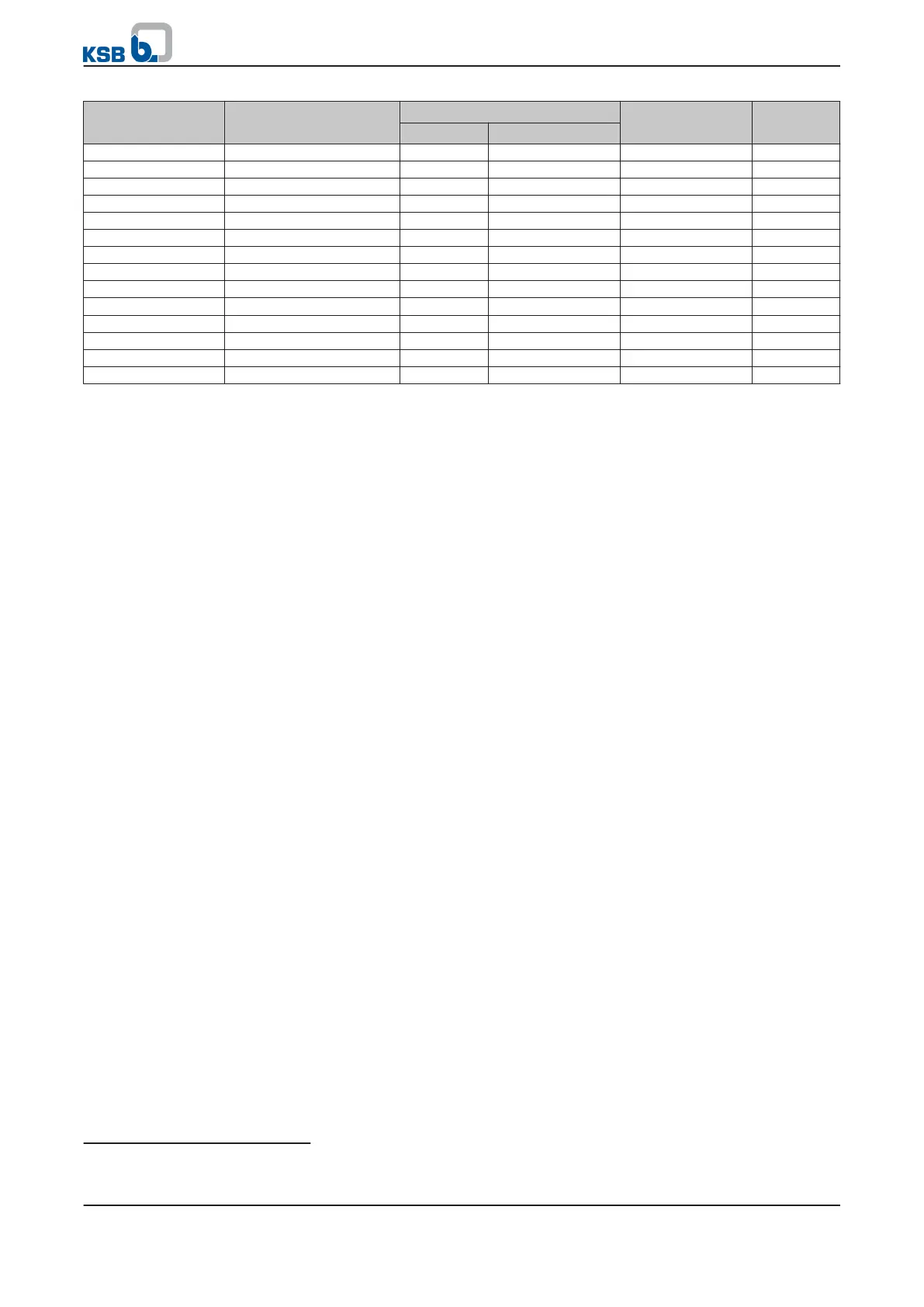

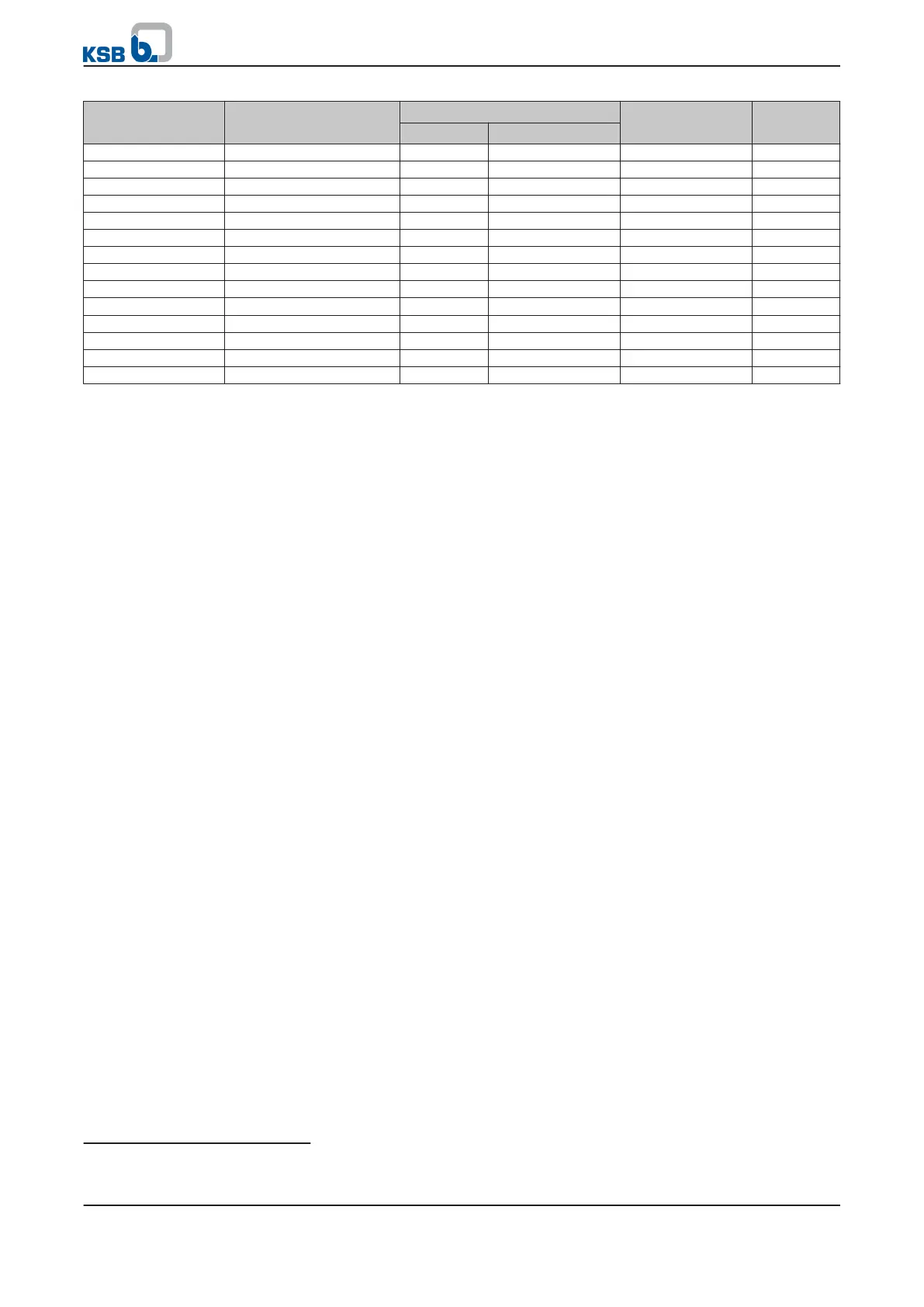

Parameter Description Possible settings Unit Factory

setting

33)

Min. Max.

3-12-3-14

H_0 0 9999 m 0

3-12-3-15

H_1 0 9999 m 0

3-12-3-16

H_2 0 9999 m 0

3-12-3-17

H_3 0 9999 m 0

3-12-3-18

H_4 0 9999 m 0

3-12-3-19

H_5 0 9999 m 0

3-12-3-20

H_6 0 9999 m 0

3-12-3-21

P_0 0 999 kW 0

3-12-3-22

P_1 0 999 kW 0

3-12-3-23

P_2 0 999 kW 0

3-12-3-24

P_3 0 999 kW 0

3-12-3-25

P_4 0 999 kW 0

3-12-3-26

P_5 0 999 kW 0

3-12-3-27

P_6 0 999 kW 0

7.2.2.2 Characteristic curve control based on the flow rate (Advanced function)

Characteristic curve control provides effective protection of the pump against

hydraulic overload or low load on the basis of the current flow rate. The current flow

rate for characteristic curve control can be determined by two methods:

▪ Measured: Via a flow rate sensor

▪ Estimated: Based on the pump characteristic curve parameterised (H/Q or P/Q).

For parameterising the pump characteristic curve/flow rate estimation (⇨ Section

7.2.2.1 Page 76) and (⇨ Section 7.2.2.3.1 Page 80)

If impermissible operating conditions are detected, PumpDrive can, after a specified

time delay, respond either with a warning or by tripping (Stop&Trip) or not respond

at all. (⇨ Section 7.2.3 Page 82)

In order to prevent starting and stopping of pumps in a multiple pump configuration

via flow rate estimation within the scope of characteristic curve control, the Q Hi

Timeout Fn

(3-12-4-3)

and Q Lo Timeout Fn

(3-12-4-6)

parameters must be set to No

Function in a multiple pump configuration, as otherwise the control quality will be

impaired.

Multiple pump

configuration

33)

Pump-specific values are preset during factory parameterisation.

7 Commissioning/shutdown

78 of 162

PumpDrive

Loading...

Loading...