Repair manual KTM 125 / 200

Art No 3.206.005 -E

5-2C

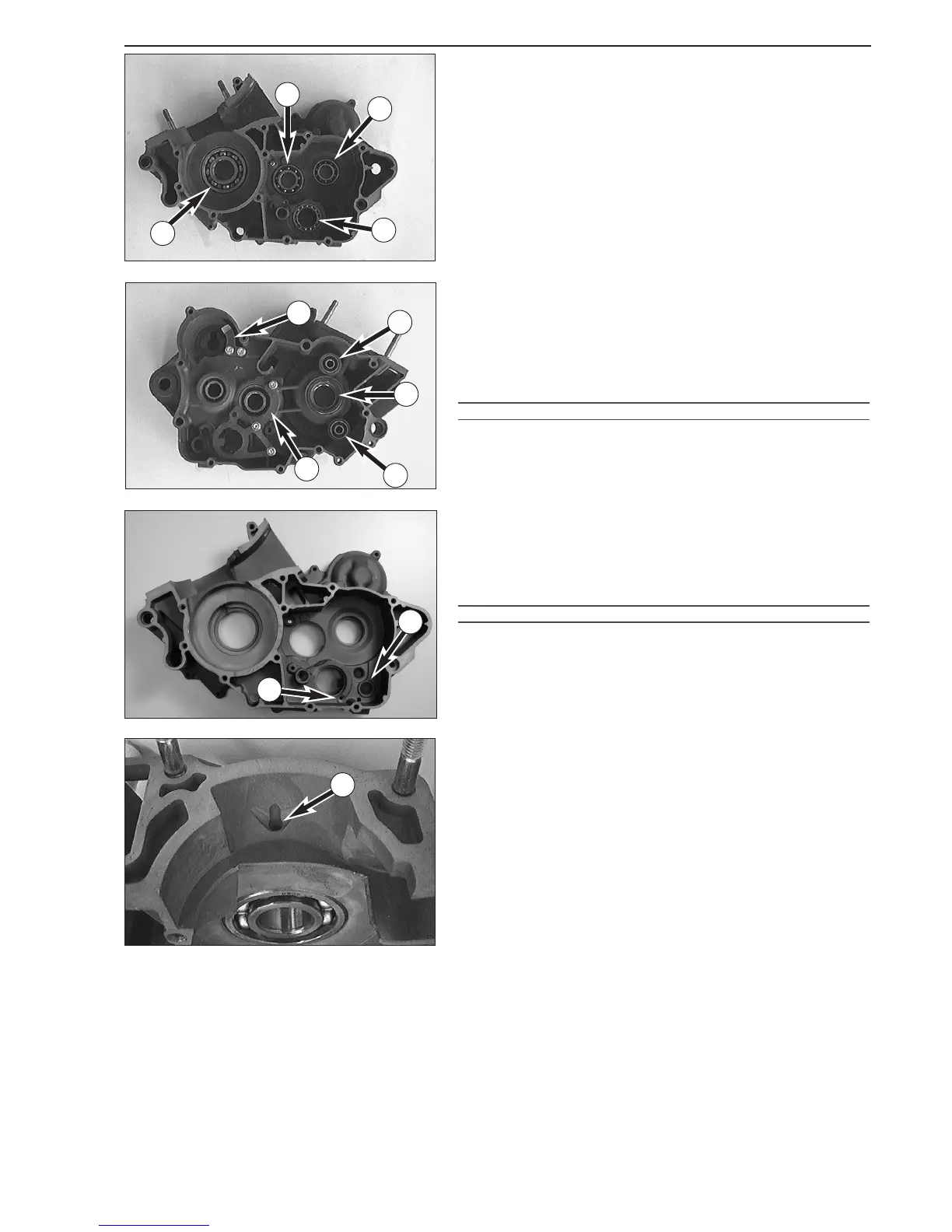

Right housing half

Remove the shaft seal rings and use a hot plate to heat the housing half

to a temperature of approximately 150° C.

NOTE: At a temperature of 150° C it is usually sufficient to tap the

housing half onto a plane wooden surface and the bearings will simply

drop out of the bearing seats. However, in some cases it is necessary to

press the bearings out of their seats. To prevent damaging of the

bearings, the device used to press in the new bearings must be designed

in such a way that it touches only the outer ring of the bearing.

Grooved ball bearing of the crankshaft

1

Press the old grooved ball bearing inwards from the outside. Insert a

new grooved ball bearing with the open side of the ball cage facing

downwards (i.e. towards the exterior) and press it all the way into the

seat.

Grooved ball bearing of the main shaft

2

Apply a suitable mandrel on the outside to press the grooved ball

bearing inwards.

Before pressing the new grooved ball bearing inwards, mount the gear

shifting gate

bk. Then, the grooved ball bearing can be pressed in from

the inside and up to the stop.

!

CAUTION

!

A

PPLY ONLY A LIGHT PRESSURE WHEN PRESSING IN THE GEAR SHIFTING GATE.

O

THERWISE

, YOU WILL DAMAGE THE SHIFTING GATE.

Grooved ball bearing of the countershaft

3

Apply a suitable mandrel on the outside to press the old grooved ball

bearing inwards. Insert a new grooved ball bearing from the inside and

press it all the way into the seat.

Grooved ball bearing of the shift roller

4

Apply a suitable mandrel on the outside to press the old grooved ball

bearing inwards. Insert a new grooved ball bearing from the inside and

press it all the way into the seat.

!

CAUTION

!

–MODEL 2000 UPWARDS THE GROOVED BALL BEARING IS SECURED WITH A

SCREW

bl, THIS IS TO BE REMOVED BEFORE PRESSING OUTWARDS THE BEARING

AND TO BE MOUNTED AFTER PRESSING INWARDS THE BEARING

.

D

UE TO THIS SCREW THE SHIFT ROLLER HAS CHANGED, AN „OLD“ SHIFT ROLLER

IS NOT ABLE TO MOUNT WITH A SCREW SECURING THE BEARING

.

–D

O NOT APPLY EXCESSIVE FORCE WHEN PRESSING THE GROOVED BALL BEARINGS

FLUSH WITH THE COLLAR IN THE HOUSING

. THE COLLAR WALL IS VERY THIN AND

CAN EASILY BE DAMAGED

!

Needle bearing of the shifting shaft

5 (from model 2002 on)

Use a suitable mandrel to press out the needle bearing. Insert the new

needle bearing and press it all the way in.

Grooved ball bearing of the centrifugal timer

6

Use an interior extractor and a Ø 5-7 mm insert to pull the grooved ball

bearing out of the housing. Press a new grooved ball bearing all the way

into the seat.

Grooved ball bearing of the water pump shaft

7

Use an interior extractor and a Ø 5-7 mm insert to pull the grooved ball

bearing out of the housing. Press a new grooved ball bearing all the way

into the seat.

Kickstarter release plate

8

When exchanging the release plate keep in mind to apply Loctite 243 to

both bolts.

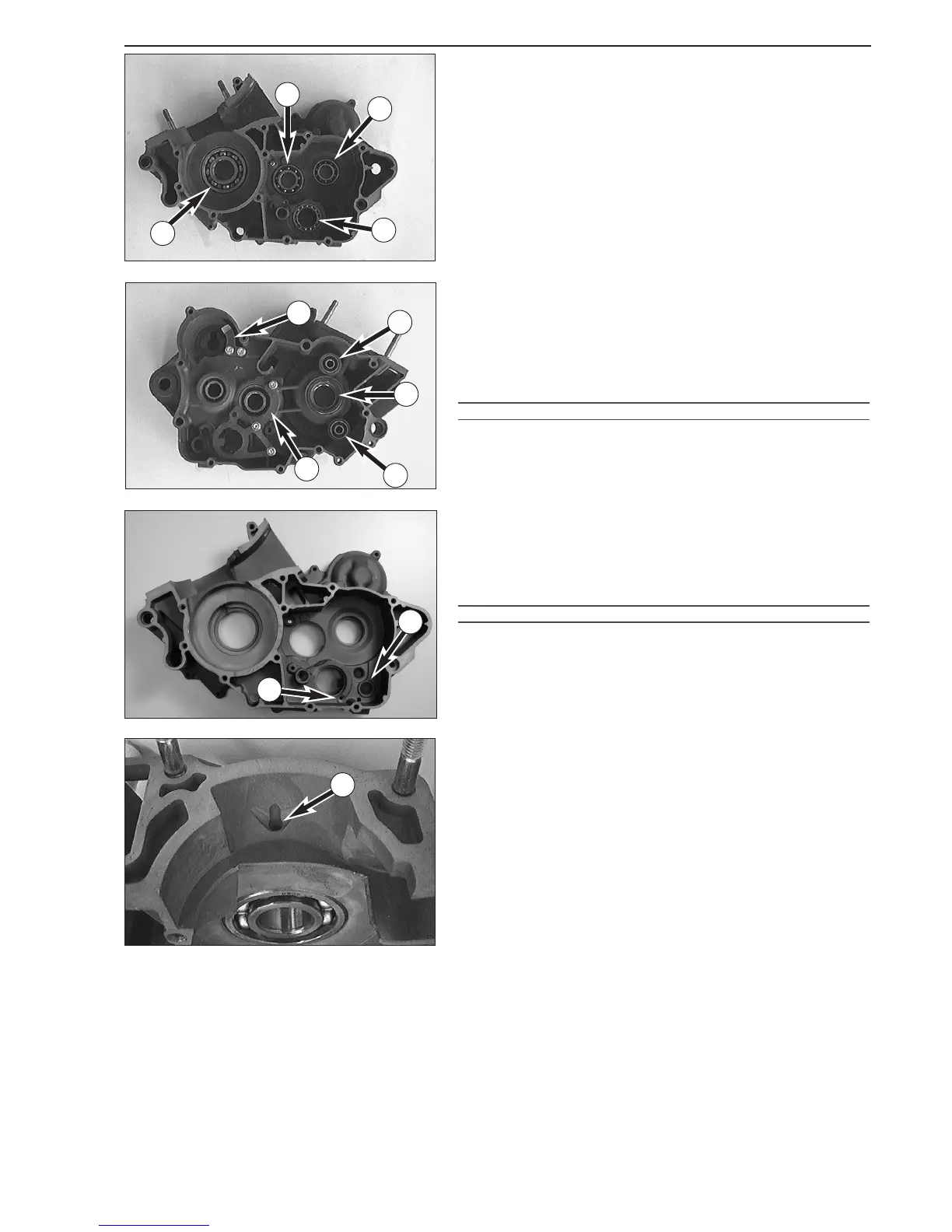

Shaft seal ring of the crankshaft

9

Insert a new shaft seal ring from the outside and press it in flush, the

open side facing inwards.

Then check the lubrication bore for the grooved ball bearing

S of the

crankshaft for obstructions.

1

2

3

4

6

7

8

9

S

10

5

11

Loading...

Loading...