1

2

6-9C

Piston, cylinder

– Carefully oil the sliding points of all components before mounting.

– Insert the needle bearing into the conrod eye, mount the piston (the

arrow on the piston head indicates the direction of the exhaust port).

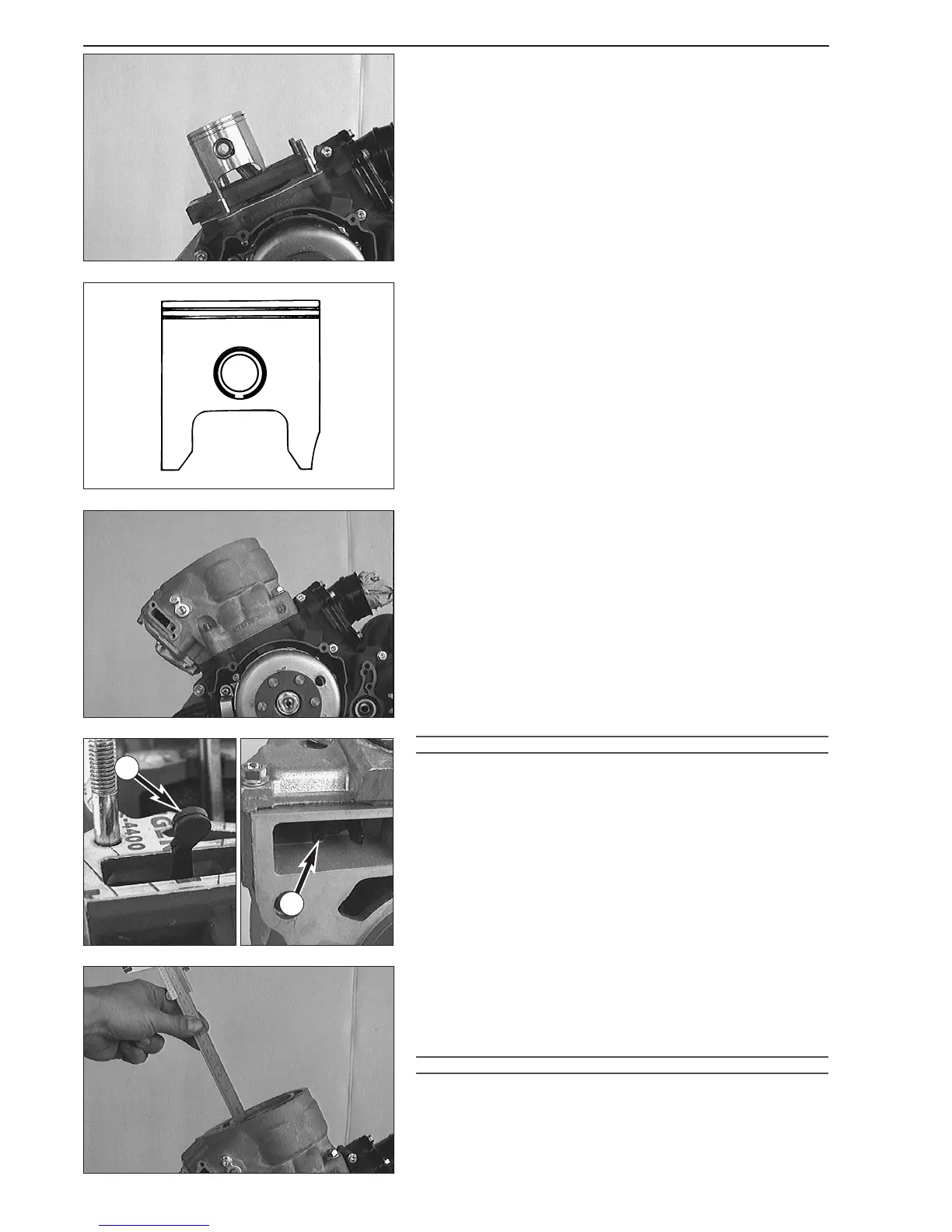

– Mount the piston pin and the wire circlips with the open side facing

downwards (see illustration).

– Mount the cylinder base gaskets (recommended gasket thickness:

approx. 0.60 mm / 0.024 in).

– Place the piston on a self-made wooden mounting device and align

the piston rings.

– Mount the preassembled cylinder, remove the mounting device and

clamp the cylinder down with two collar nuts.

!

CAUTION

!

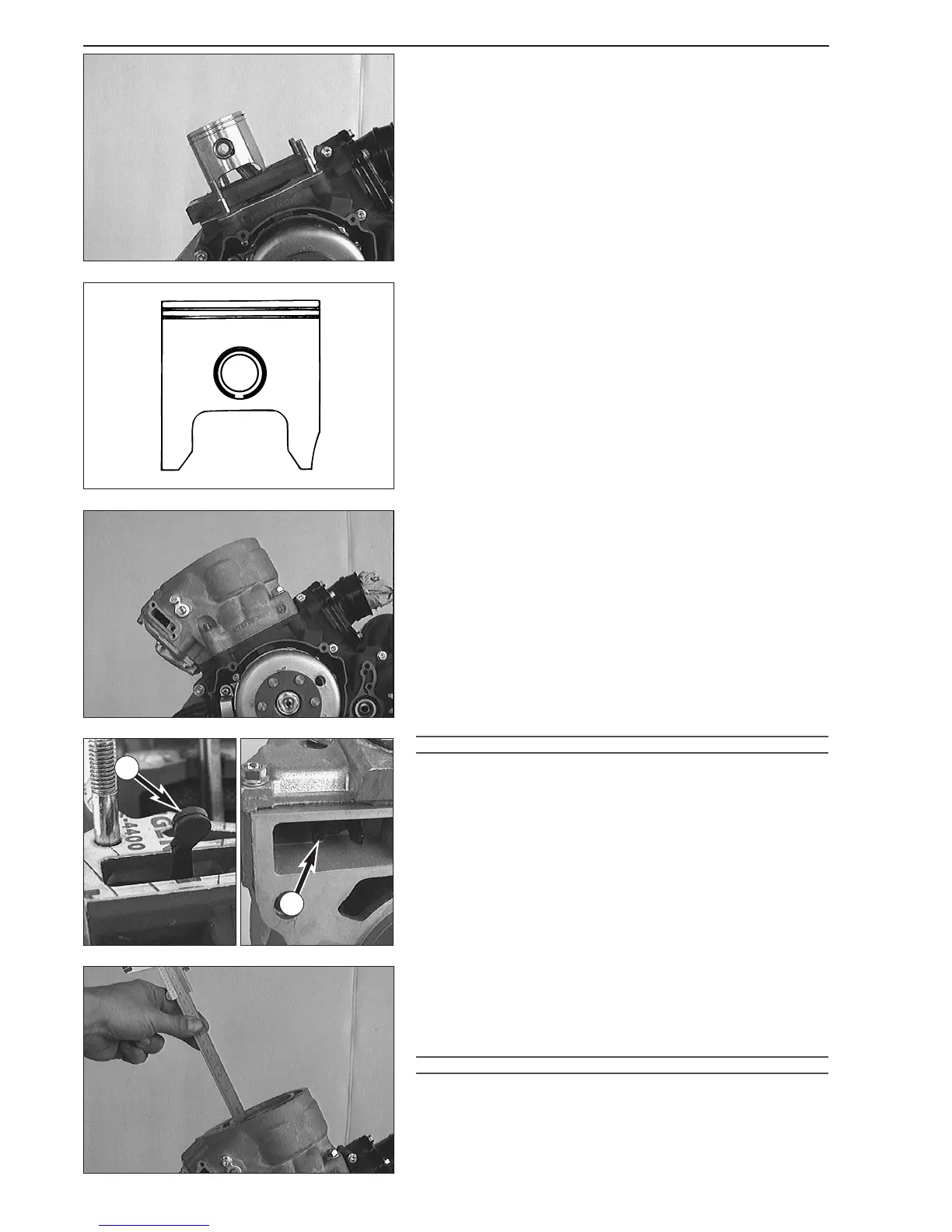

W

HEN MOUNTING THE CYLINDER MAKE SURE THAT THE ROCKER ARM 1 OF THE

CENTRIFUGAL TIMER IS LOCATED IN THE CORRESPONDING RECESS

2 OF THE CON-

TROL SEGMENT IN THE CYLINDER. IF NECESSARY REMOVE THE SMALL CAP ON THE

RIGHT SIDE OF THE CYLINDER AND CHECK

.

Adjusting dimension „X“

NOTE: Dimension „X“ is the distance between the upper piston edge

and the offset upper cylinder edge with the cylinder clamped down and

the piston in position TDC.

Dimension „X“ must be adjusted particularly carefully by inserting

cylinder base gaskets of different thicknesses.

!

CAUTION

!

I

F DIMENSION „X“ IS TOO LARGE, THE COMPRESSION VALUE WILL DECREASE, THUS

REDUCING THE OVERALL ENGINE OUTPUT

. IF DIMENSION „X“ IS TOO SMALL, THE

ENGINE WILL

„PINK“ AND OVERHEAT.

Loading...

Loading...