2RV/2RW/2RX/2RY/3RA-3

7-66

J4211/J4212/J4213/J4218/J4219: Exit sensor stay jam

Condition: Paper jam at FD guide

When feeding from cassette 1-3, duplex or MP tray, paper jam occurs at the feed-shift section and the exit

sensor does not turn off.

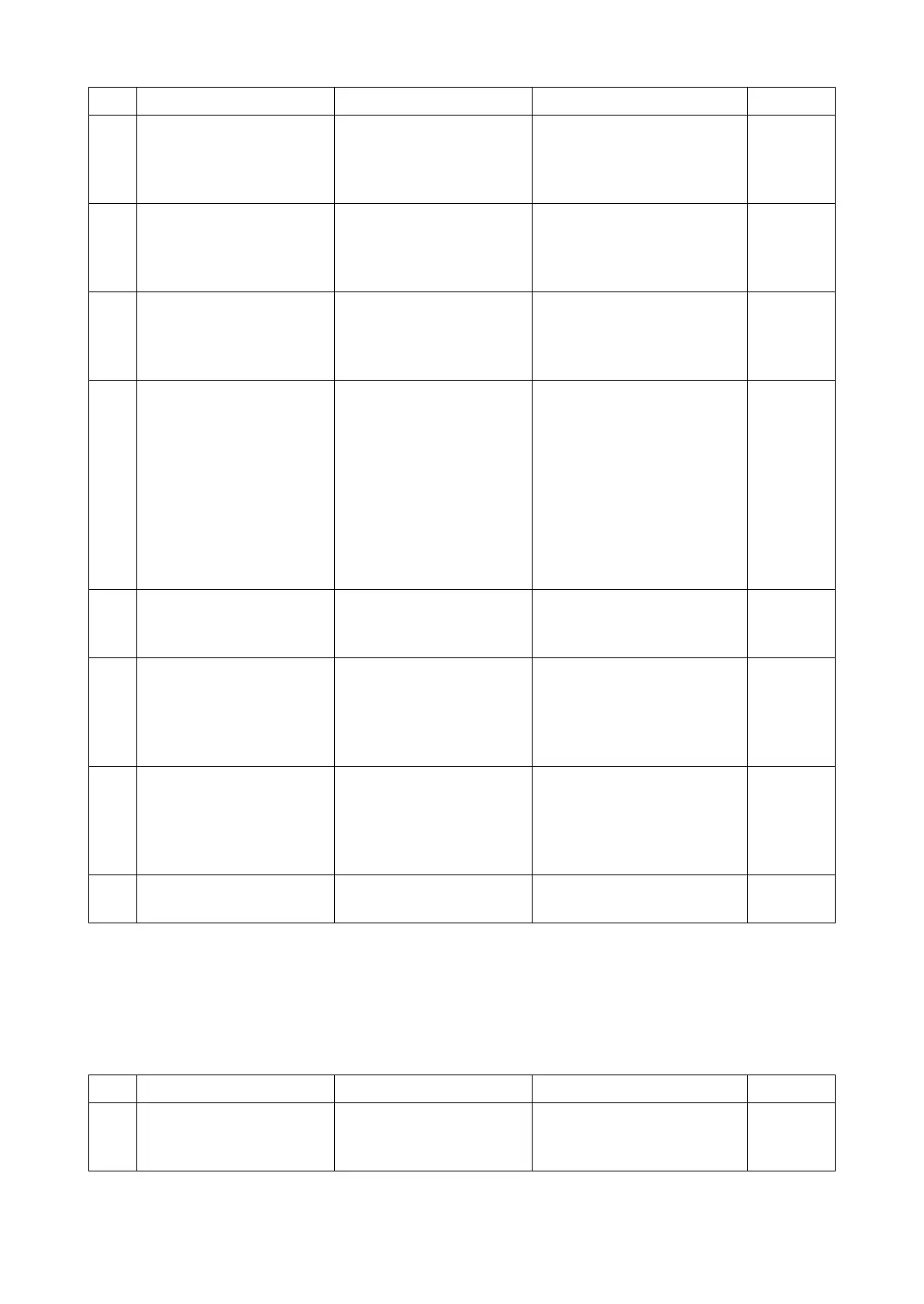

5 Checking the upper exit

roller and upper exit pulley

The upper exit roller con-

veying force is not enough.

Clean the surface of the

upper exit roller and upper

exit pulley. If worn down,

replace them.

6 Checking the driving parts The exit roller does not

rotate.

In case the drive gear is

deformed, torque limiter is

faulty or bushing is worn

down, replace the exit unit.

7 (In case the sensor does

not turn on with paper)

Reattaching the fuser unit

or exit unit

The fuser unit or exit unit is

not attached properly.

Reattach the fuser unit and

exit unit, and reconnect the

exit unit connector.

8 Checking the connection The connector is not prop-

erly connected or the wire

is faulty.

Clean the terminal of the fol-

lowing wire connectors and

reconnect the connectors. If

there is no continuity, replace

the wire.

• Main motor - Main/engine

PWB (YC9)

• Exit sensor - Main/engine

PWB (YC19)

9 Checking the main motor The main motor does not

operate properly.

Reattach the main motor and

reconnect the connector. If

not repaired, replace it.

10 Checking the actuator and

the spring

The actuator does not

operate properly.

Reattach the actuator and

spring for the exit sensor. If

faulty due to deformation,

etc., correct it. If not repaired,

replace the fuser unit.

11 Checking the exit sensor The exit sensor does not

properly operate.

Clean the exit sensor, reat-

tach it and reconnect the con-

nector. If not repaired,

replace the fuser unit (includ-

ing the exit sensor).

12 Replacing the main/engine

PWB

The main/engine PWB is

faulty.

Replace the main/engine

PWB.

Step Check description Assumed cause Measures Reference

1 Checking the paper Unspecified papers are

used.

Explain to the user to use the

paper within the specifica-

tions.

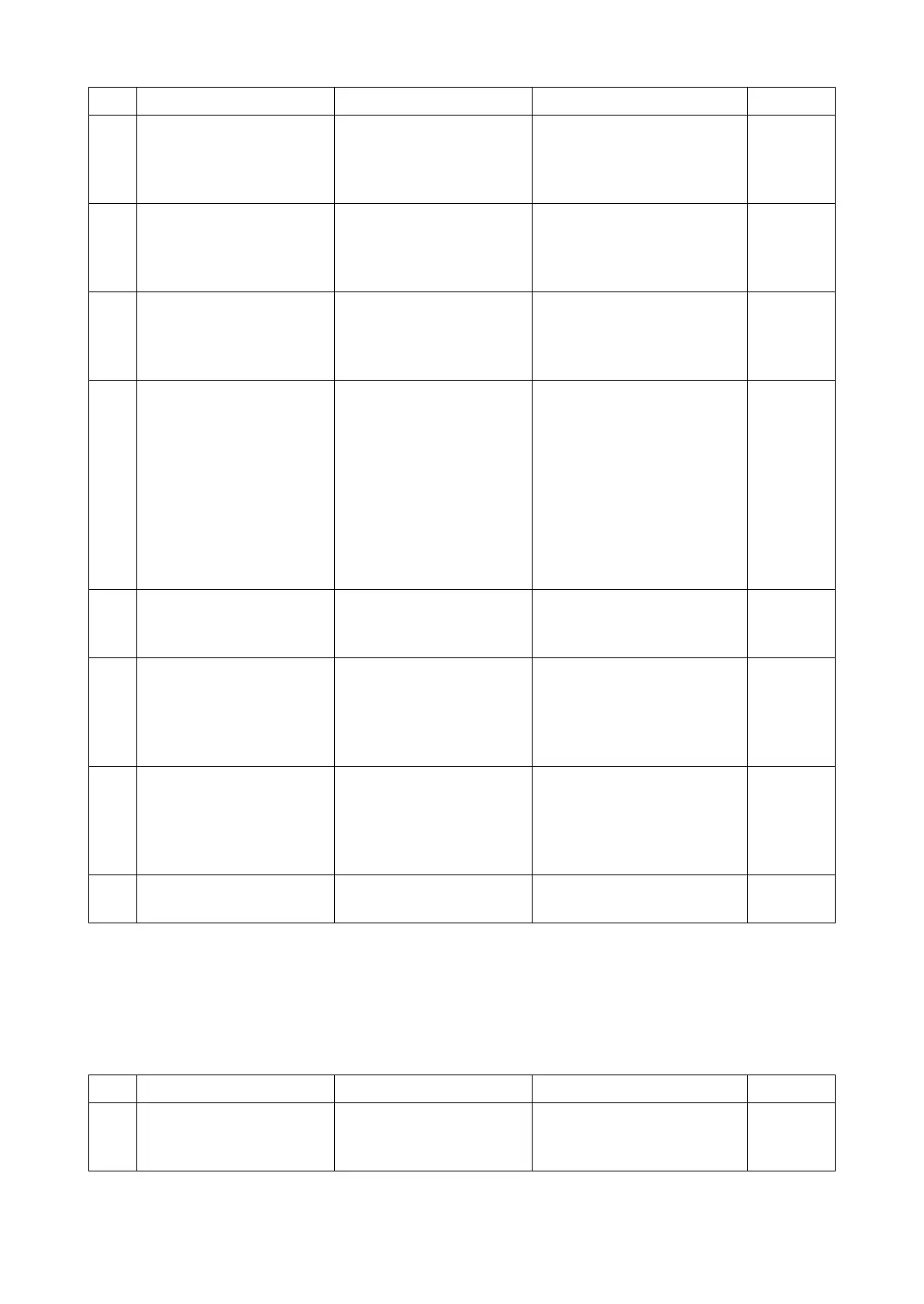

Step Check description Assumed cause Measures Reference

Loading...

Loading...