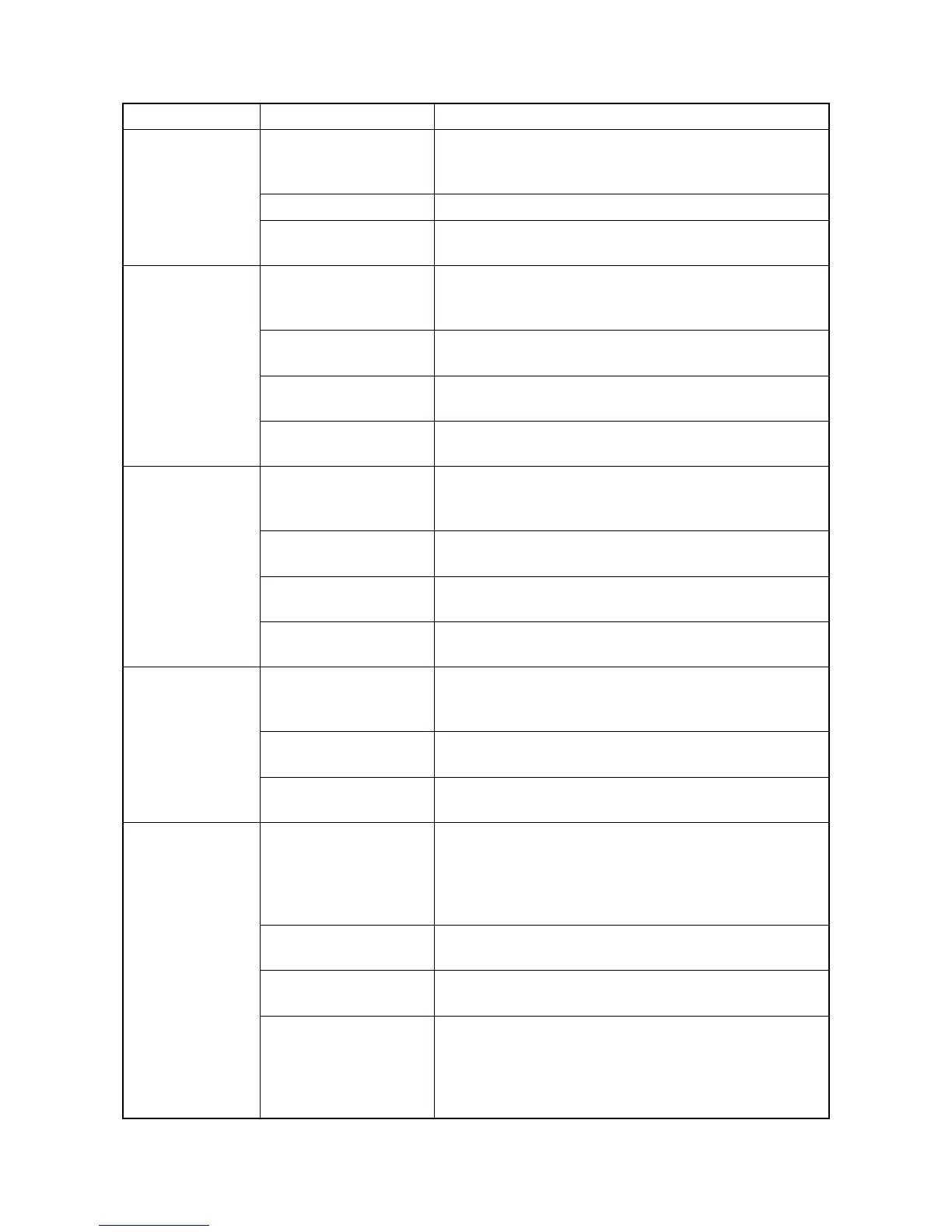

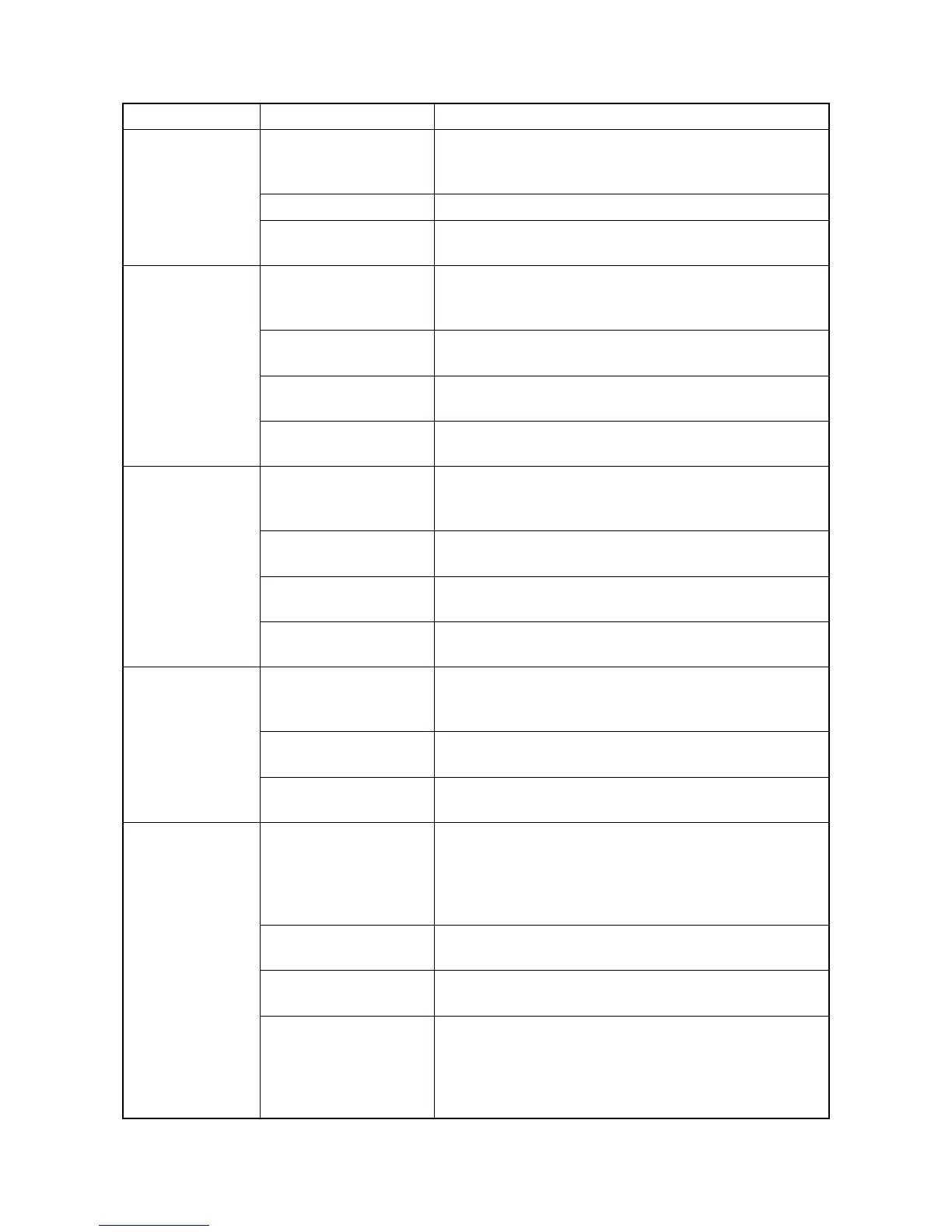

2KT/2KV

1-4-38

(11)

MP solenoid does

not operate.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

MP solenoid and engine PWB (YC4)

2. Defective solenoid. Replace the MP solenoid.

3. Defective PWB. Replace the engine PWB and check for correct operation

(see page 1-5-26).

(12)

The message

requesting paper to

be loaded is shown

when paper is

present on the cas-

sette.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

Cassette PWB (YC1) and engine PWB (YC21)

2. Deformed actuator of

the paper sensor.

Check visually and replace if necessary.

3. Defective paper sen-

sor.

Replace the cassette PWB.

4. Defective PWB. Replace the engine PWB and check for correct operation

(see page 1-5-26).

(13)

The message

requesting paper to

be loaded is shown

when paper is

present on the MP

tray.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

MP paper sensor and engine PWB (YC16)

2. Deformed actuator of

the MP paper sensor.

Check visually and replace if necessary.

3. Defective MP paper

sensor.

Replace the MP paper sensor.

4. Defective PWB. Replace the engine PWB and check for correct operation

(see page 1-5-26).

(14)

The size of paper

on the cassette is

not displayed cor-

rectly.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

Cassette size switch and engine PWB (YC17)

2. Defective cassette

size switch.

Replace the cassette size switch.

3. Defective PWB. Replace the engine PWB and check for correct operation

(see page 1-5-26).

(15)

A paper jam in the

paper feed, paper

conveying or eject

section is indi-

cated when the

main power switch

is turned on.

1. A piece of paper torn

from paper is caught

around registration

sensor, MP feed sen-

sor or eject sensor.

Check visually and remove it, if any.

2. Defective registration

sensor.

Replace the registration sensor.

3. Defective MP feed

sensor.

Replace the MP feed sensor.

4. Defective eject sen-

sor.

Replace the eject PWB.

Problem Causes Check procedures/corrective measures

Loading...

Loading...