n Avoid chlorine content in the water at all costs. Do not add chlorine

to the water. Cleaning agents and disinfectants, for example, contain

chlorine.

n The water must be free of impurities. Water with iron content is unsuit-

able due to rust formation and untreated river water is unsuitable due to

algae growth.

n The addition of ammonia is not permitted.

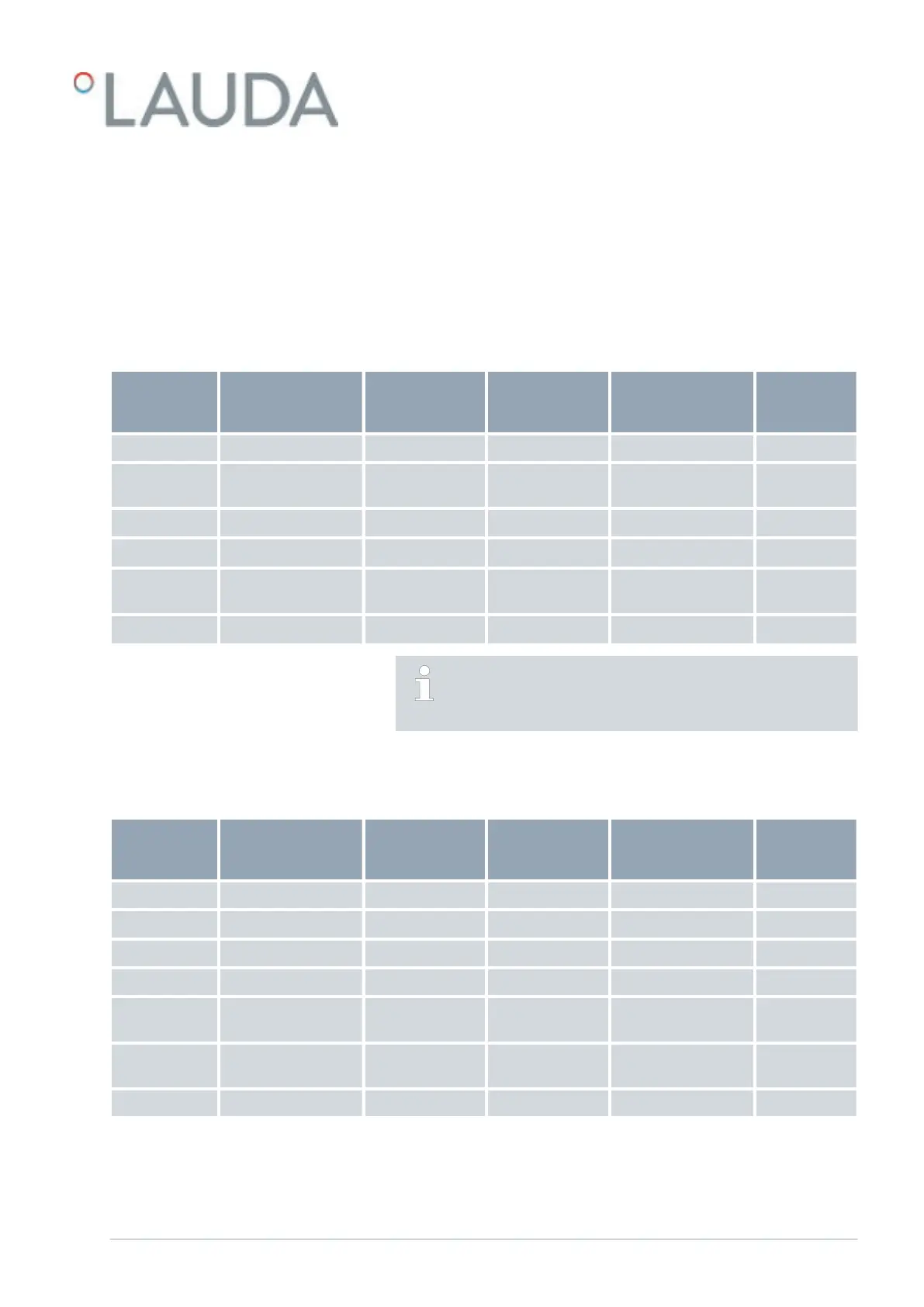

Table 4: Permissible heat transfer liquids for Integral T

Designation

Chemical characteri-

zation

Working tem-

perature range in

°C

Viscosity (kin) in

mm²/s at 20 °C

Viscosity (kin) in

mm²/s at tem-

perature

Flash point

in °C

Kryo 51 Silicone oil -50 – 120 5 34 at -50 °C 120

Kryo 30

Monoethylene glycol/

water mixture

-30 – 90 4 50 at -25 °C ---

Kryo 20 Silicone oil -20 – 170 11 28 at -20 °C 170

Aqua 90

1

Decalcified water 5 – 90 1 --- ---

Ultra 350

Aromatic hydro-

carbon

30 – 200 48 16 at 40 °C 212

Ultra 301

2

Mineral oil 40 – 230 76.5 35.4 at 40 °C 245

Please note:

1

Aqua 90 or water may only be used in the Integral 130 T and

230 T(W) devices.

2

Recommendation: Overlay with nitrogen at 150 °C and above

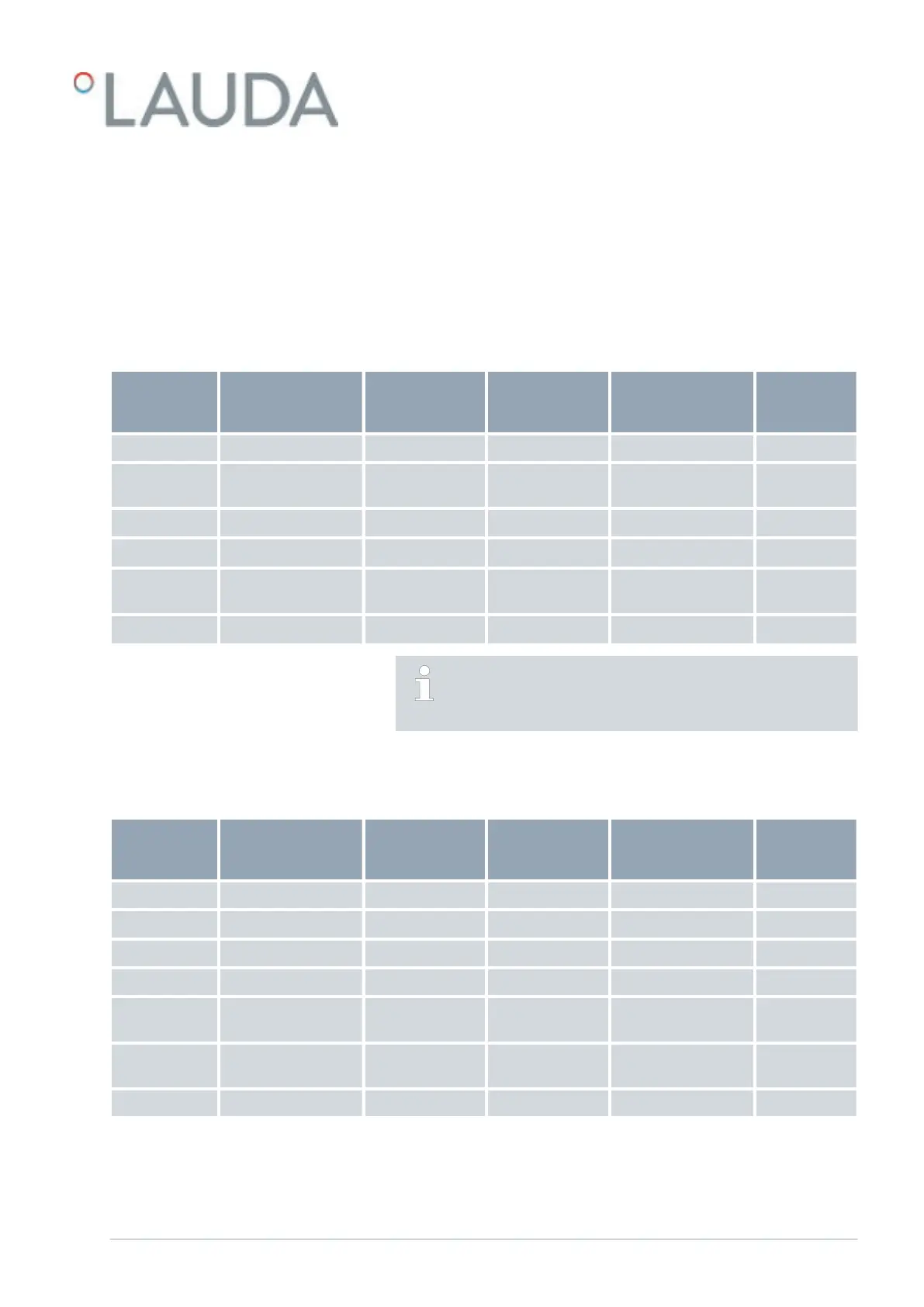

Table 5: Permissible heat transfer liquids for Integral XT (closed system)

Designation

Chemical characteri-

zation

Working tem-

perature range in

°C

Viscosity (kin) in

mm²/s at 20 °C

Viscosity (kin) in

mm²/s at tem-

perature

Flash point

in °C

Kryo 95 Silicone oil -95 – 160 1.6 20 at -80 °C 64

Kryo 71 Silicone oil -70 – 220 5.3 44 at -60 °C 125

Kryo 70 Silicone oil -70 – 220 5 42 at -60 °C 121

Kryo 65 Hydrocarbon -65 – 140 1.7 10 at -40 °C 62

Kryo 30

1

Monoethylene glycol/

water mixture

-30 – 90 4 50 at -25 °C ---

Ultra 350

2

Aromatic hydro-

carbon

30 – 350 48 16 at 40 °C 212

Ultra 301 Mineral oil 40 – 300 76.5 35.4 at 40 °C 245

Please note:

n

1

Do not use Kryo 30 in devices with cascade cooling.

n

2

Use Ultra 350 for the Integral high-temperature thermostats.

V6 Integral Process Thermostats and High-Temperature Thermostats 41 / 198

Loading...

Loading...