5.4303.8558.0 -

7-10 Maintenance

The metal strip must be installed in its original place. If the machine does

not find the metal strip on the same location it can get lost on the route

and generate an alarm.

1. Take the machine out of operation.

2. Manually drive the machine to a clean and quiet location.

Examine

1. Examine if all metal strips in the route are installed correctly to the floor.

2. Determine if you must:

1. Replace screws.

2. Replace a metal strip.

Replace Screws

Do not use an impact wrench.

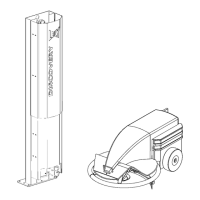

Only the hole (A) in the center is round. The holes B and C are slots to

allow the metal strip to shrink and expand a bit with temperature

changes. The metal strips are not symmetrical. If (after some time) a hole

in the concrete can not be used anymore, you can turn the strip over the

long side and drill new holes in the concrete.

If one or more screws must be replaced:

1. Remove all screws of the strip.

2. Turn the strip around over the long side so the holes in the strip do not match the old holes in the

floor.

3. Mark the position of the holes. Start to mark the hole in the center (A) of the strip. Mark the slotted

holes (B) and (C) in the center of the holes.

4. Drill new holes in the floor with a 10 mm drill and >65 mm deep.

5. Clean the holes.

6. Insert S10 plugs.

7. Use a bit T30 to tighten the metal strip with the screws (BT 6x65). Tighten only with a torque of 20 Nm.

It must still be possible that the metal strip can shrink and expand a bit when temperature changes

occur.

in n o vato rs in agriculture

Loading...

Loading...