19. Sequence of Operation

Page 90

506457−01 05/10

AI1

D01

HUM

TMP

D02

DI1

DI2 DI3

DI4

SENSOR

IAQ

Y2

THERMOSTAT

24VAC

C

R

W1

W2 Y1GRC

24VAC

HUMIDISTAT

OUTPUTSSENSOR INPUTS

24VAC

R C

SMOKE

R R

C

G

OCP

O

L

1

AFTERMARKET

RTU CONTROL-

LER

1

SEE AFTERMARKET CONTROLLER INSTALLATION

INSTRUCTIONS FOR WIRING INFORMATION.

24VAC

COMMON

VENTILATION DEMAND

HEATING DEMAND ONE

HEATING DEMAND TWO

COOLING DEMAND ONE

COOLING DEMAND TWO

OCCUPIED DEMAND

1

BYPASS

DAMPER

1

SUPPLY STATIC

PRESSURE

SENSOR

1

OPTIONAL

BUILDING STATIC

PRESSURE SWITCH

OR SENSOR

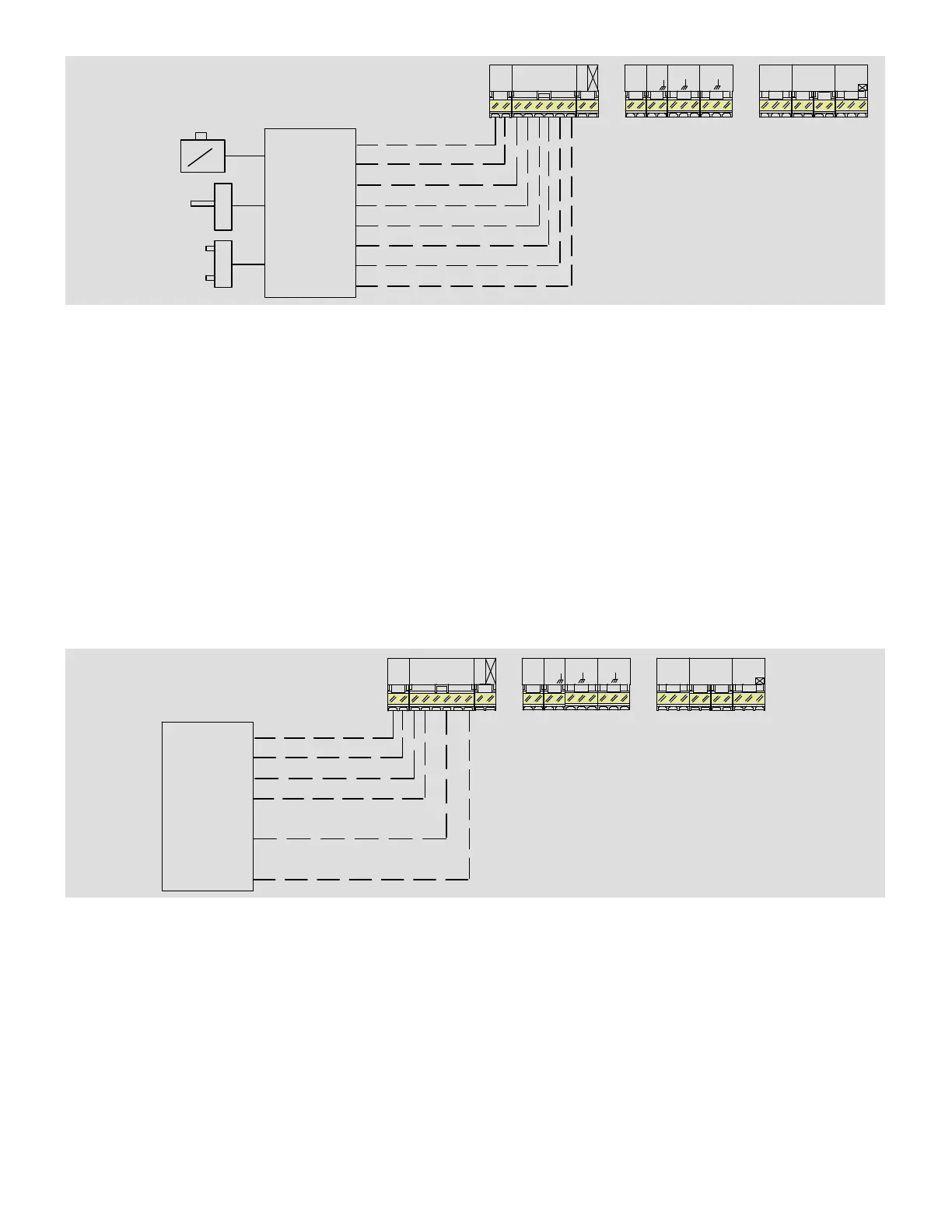

Figure 38. Constant Air Volume Unit in Bypass Zoning Application

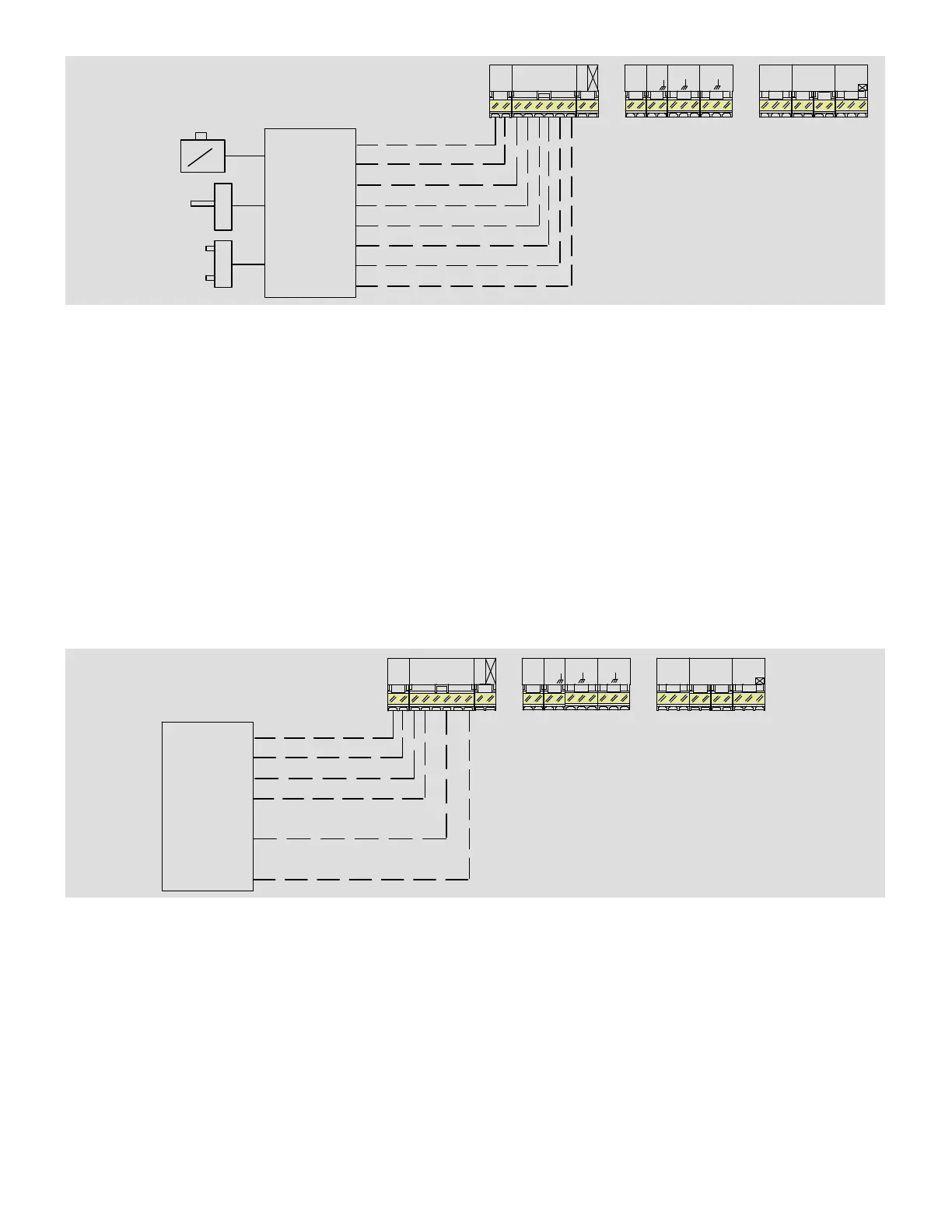

When in thermostat mode and configured for discharge air temperature control, the unit controller can provide up to four

stages of mechanical heating and cooling operation. Variable air volume units using a variable frequency drive on the supply

fan and operating in a zoning application must use this control mode. Although not as common, constant volume units in

either single zone or bypass zoning applications may also use this control mode. To operate correctly, a Lennox or third−

party thermostat or unit control must provide the following wiring connections to the unit controller:

1. Ventilation demand

2. Occupied demand

3. Heating demand

4. Cooling demand

In this control mode the unit controller will control all cooling and heating staging to maintain the the discharge air tempera-

ture setpoints set in the unit controller (typically 55°F for cooling and 110°F for heating). A third−party unit control, or a ther-

mostat can provide these inputs to the unit controller. For example, if the unit control passes along a demand for cooling then

the unit controller will activate the refrigeration system and increase or decrease cooling stages to maintain the discharge

supply air temperature setpoint. In this mode, the unit controller will also maintain the supply duct static pressure by directly

controlling the supply fan variable frequency drive. Along with providing control of the rooftop unit, the unit controller will also

provide error codes and diagnostic information.

AI1

D01

HUM

TMP

D02

DI1

DI2 DI3

DI4

SENSOR

IAQ

Y2

THERMOSTAT

24VAC

C

R

W1

W2 Y1GRC

24VAC

HUMIDISTAT

OUTPUTSSENSOR INPUTS

24VAC

R C

SMOKE

R R

C

G

OCP

O

L

AFTERMAR-

KET RTU CON-

TROLLER OR

THERMOSTAT

24VAC

COMMON

VENTILATION DEMAND

HEATING DEMAND

COOLING DEMAND

OCCUPIED DEMAND

Figure 39. Variable Air Volume Unit in Zoning Application

19.1.3. Operations Common to All Rooftop Units

The following sequence of operation information applies to all Energence rooftop units regardless of unit controller control

mode, unit type or zoning application.

19.1.3.1. Heating Operation (Modulating Gas)

The Energence unit features two separate gas burner sections, each with a modulating gas valve and a shut−off valve. The

modulating gas heat section can provide continuous operation from 25−100% of total heat capacity. Upon receiving a heat-

ing demand, the unit controller will instruct the modulating gas unit to maintain a discharge air temperature setpoint (default

110°F). The unit maintains this setpoint by feeding information from a discharge air temperature sensor located in the supply

duct back to the unit controller. Based on this information, the unit controller increases or decreases gas heat output to

maintain the desired heating setpoint.

Loading...

Loading...