If inverter technology is required; suitable in-line ltering between the inverter

and the pump system must be applied. The ltering must reduce the total

harmonic distortion of the supply voltage to less than 5%. Please consult the

inverter manufactur

er for more details on the type of lter required.

In addition to the in-line ltering, the correct fuse protection is still required.

Refer to tables in

on page 30.

Make sure the access to the pump electrical supply cable is not obstructed

when locating the pump.

If using an earth leakage current device, for example a Residual Current

Device (RCD), use a 30 mA (minimum) rated unit to avoid nuisance tripping

during start up.

Note:

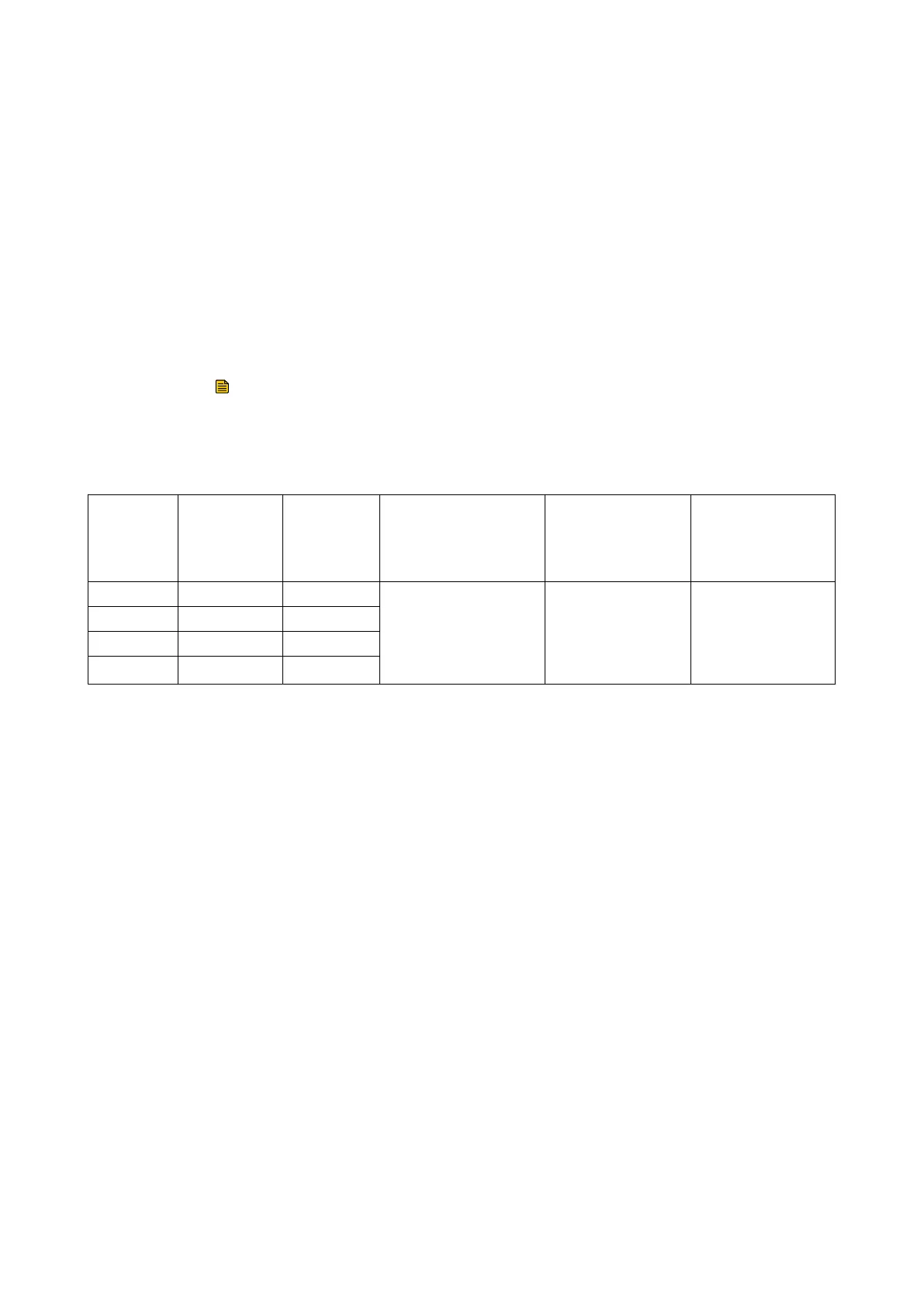

Table 8 Input supply

Voltage

(a.c. rms)

Frequency

(Hz)

Rated sys‐

tem input

curr

ent

(A rms)

Minimum wire gauge

(4 wire: 3-phase+PE)

Recommended

wire

temperature

Recommended UL

style number

200 50 2.5

16 AWG/1.5 mm

2

105 °C UL1015

200-208 60 2.5

380-415 50 1.25

460

60 1.25

The recommended overall cable gauge, including 3 live wires and a PE wire

with the individual wire specication dened in the table, is approximately

9.6 mm outer diameter. The M20 cable gland on the front panel of the pump

is suitable for a cable diameter range: 5‑12 mm.

Use the following procedure to connect a mains cable to the 3-phase pump:

32 300668736_002_C7 - © Leybold

Installation

Loading...

Loading...