the 3-phase pump system must be installed with motor thermal overload

protection. Failur

e to install the 3-phase pump system without the specied

motor thermal overload protection could result in permanent damage to the

pump if subjected to sustained overload or fault conditions, e.g. a block

exhaust.

Furthermore, the pump housing surface temperature could reach levels

greater than 105 °C without this protection.

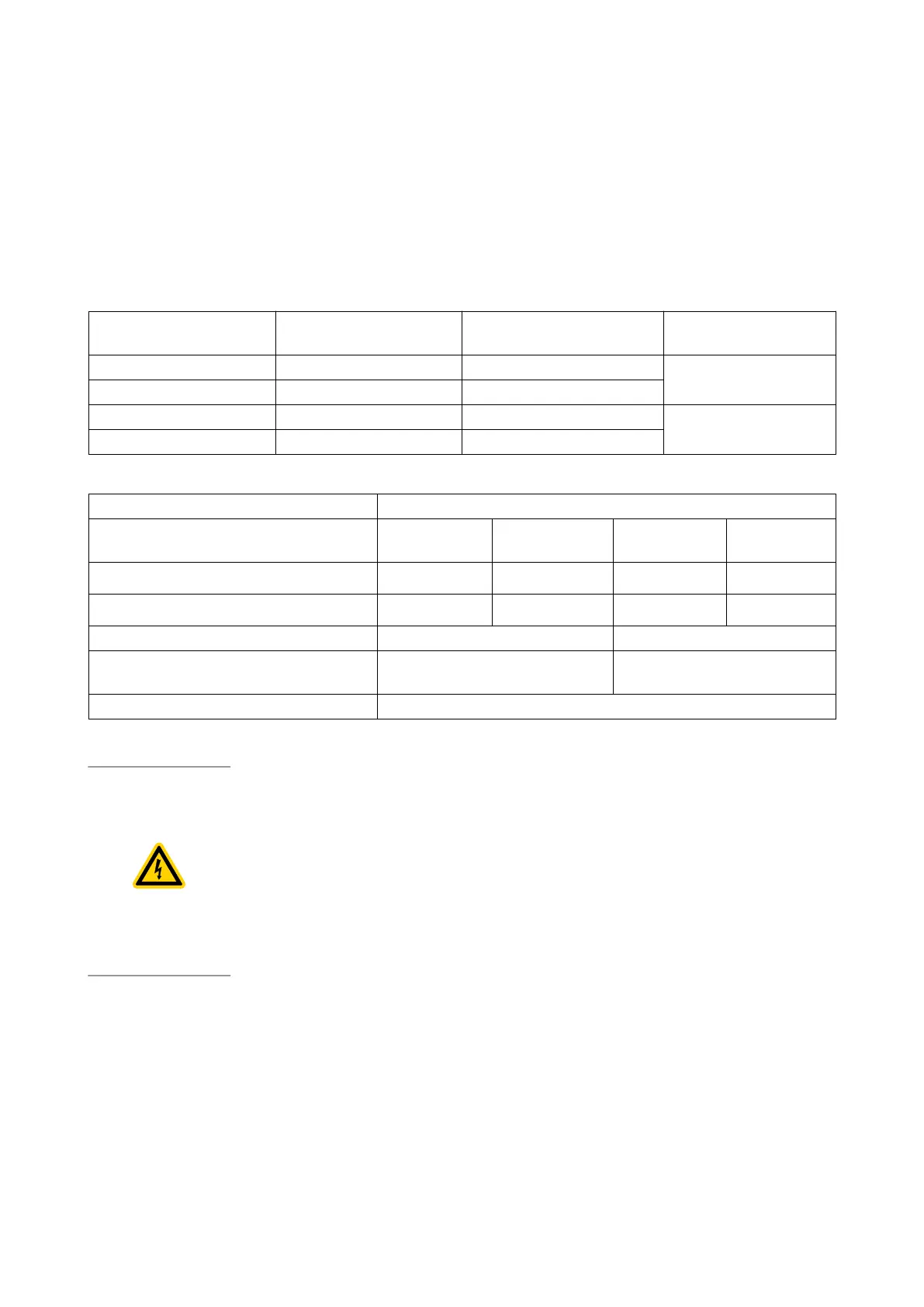

Table 6 Fuses and circuit breakers

Input supply

Rated system input cur‐

rent

Recommended external

fuse rating

Recommended fuse

type

200 V, 50 Hz 2.4 A rms 2.5 A, 250 V a.c

RK1 and RK5

200-230 V, 60 Hz 2.4 A rms 2.5 A, 250 V a.c

380-415 V, 50 Hz 1.5 A rms 1.6 A, 600 V a.c

RK1, RK5 and J

460 V, 60 Hz 1.5 A rms 1.6 A, 600 V a.c

Table 7 Recommended motor thermal overload protection

Parameter 3-phase SCROLLVAC 15, 18, 7 and 10 plus

Supply voltage and frequency

200 V,

50 Hz

200 - 230 V,

60 Hz

380 ‑ 415 V,

50 Hz

460 V,

60 Hz

Maximum COP current (A rms) 1.85 1.75 1.45 1.30

Maximum Atmospheric current (Arms) 2.15 2.75 1.55 1.50

Motor thermal overload setting (Arms) 2.40 1.50

Recommended motor thermal overload

device

ABB: T16 - 3.1 ABB: T16 - 1.7

Trip class 10

6.7.1Electrical supply connection

CAUTION: PUMP DAMAGE

The 3-phase pump system is delivered congured for high voltage use. High

voltage is dened as: 380 ‑ 415 V/50 Hz and 460 V/60 Hz. Make sure that the

pump is correctly congured for the electrical supply voltage and frequency. If not,

the embedded 3-phase motor within the pump can be damaged.

The 3-phase pump system is not designed to be powered directly from a variable

speed drive (VSD) using inverter technology. The direct use of inverter technology

will lead to increased heating within the pump system, resulting in long term

damage to the pump.

3-phase power must be connected to the 3-phase pump system. The

overall 3-phase cable must include 3 live wires and a protective earth (PE)

ground wire.

In addition to the primary 3-phase power supply connection to the pump,

the pump must also be earthed via the secondary earth connection on the

front of the pump housing using a M5x10 screw with a shake proof washer,

refer to

for more details.

The specication of this secondary earth wire must also meet the above

mentioned requirements.

300668736_002_C7 - © Leybold 31

Installation

Loading...

Loading...